Process for removing low-boiling-point organic matters in high-concentration wastewater

A technology for high-concentration wastewater and organic matter, applied in the fields of water pollutants, energy wastewater treatment, water/sewage multi-stage treatment, etc. The effect of concentration, increasing flux, and speeding up filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

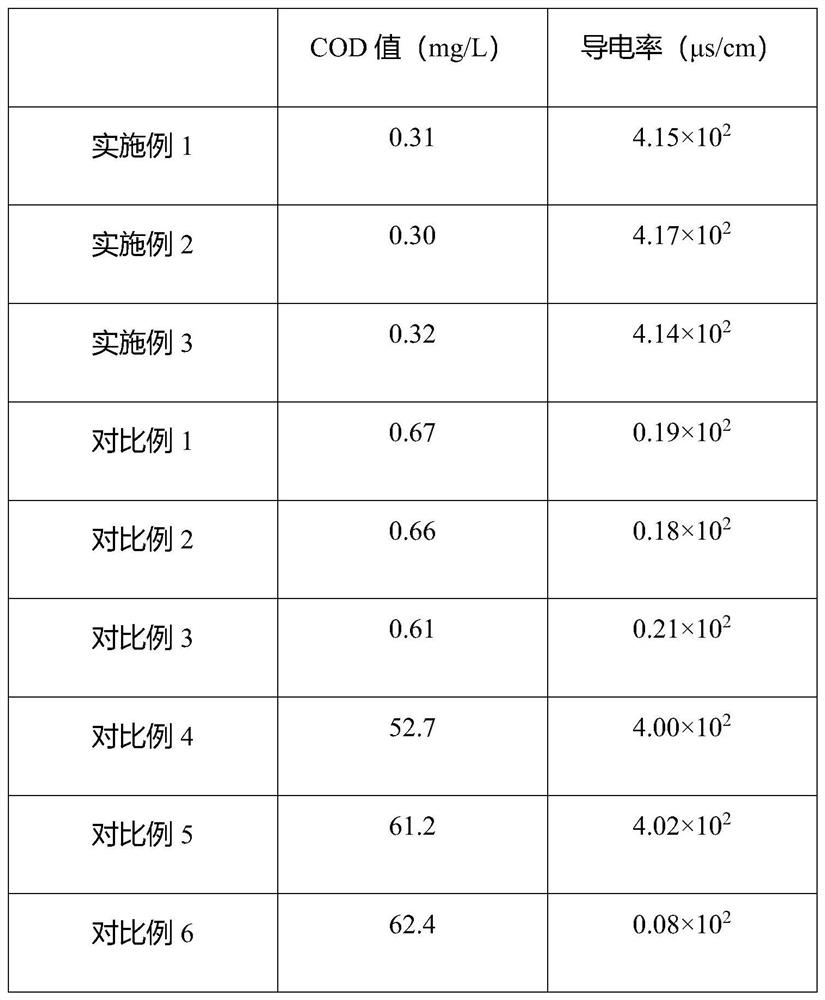

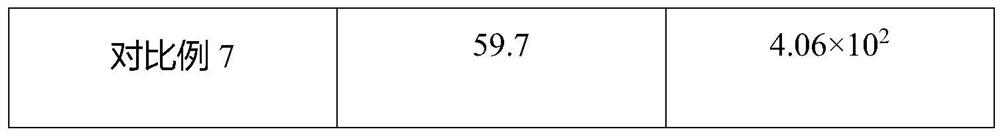

Examples

Embodiment 1

[0037] A process for removing low-boiling organic matter in high-concentration wastewater mainly comprises the following process steps:

[0038] (1) Dispose of high-concentration wastewater at 2.5m 3 / h into the ozone generator, the air flow rate is 450mL / min, the reaction temperature is 30°C, the gas phase ozone concentration is 55mg / mL, after staying for 160min, placed at room temperature for 24h to obtain pretreated wastewater;

[0039] (2) Disperse activated carbon in a hydrogen peroxide solution with 21 times the mass of activated carbon. The mass ratio of hydrogen peroxide and deionized water in the hydrogen peroxide solution is 1:6.7. After stirring for 2 hours at 50 °C and 100 rpm, vacuum thermal activation at 800 °C and 100Pa for 2 hours , washed 4 times with deionized water, filtered, and dried at 80 °C for 1 h to obtain pretreated activated carbon;

[0040] (3) place the pretreated waste water in a closed heating container, the top of the closed heating container i...

Embodiment 2

[0049] A process for removing low-boiling organic matter in high-concentration wastewater mainly comprises the following process steps:

[0050] (1) The high-concentration wastewater is 3.1m 3 / h into the ozone generator, the air flow rate is 480mL / min, the reaction temperature is 33°C, and the gas phase ozone concentration is 58mg / mL. After staying for 188min, it is placed at room temperature for 25.5h to obtain pretreated wastewater;

[0051] (2) Disperse the activated carbon in a hydrogen peroxide solution with a mass of 22 times the activated carbon. The mass ratio of hydrogen peroxide and deionized water in the hydrogen peroxide solution is 1:6.7. After stirring for 1.5 hours at 57 °C and 170 rpm, vacuum thermal activation at 861 °C and 120Pa for 2.5 After h, washed 6 times with deionized water, filtered, and dried at 80 °C for 2 h to obtain pretreated activated carbon;

[0052] (3) place the pretreated wastewater in a closed heating container, the top of the closed heat...

Embodiment 3

[0061] A process for removing low-boiling organic matter in high-concentration wastewater mainly comprises the following process steps:

[0062] (1) Dispose of high-concentration wastewater at 3.5m 3 / h into the ozone generator, the intake flow rate is 500mL / min, the reaction temperature is 35°C, the gas phase ozone concentration is 60mg / mL, after staying for 200min, placed at room temperature for 26h to obtain pretreated wastewater;

[0063] (2) Disperse the activated carbon in a hydrogen peroxide solution with a mass of 23 times the activated carbon. The mass ratio of hydrogen peroxide and deionized water in the hydrogen peroxide solution is 1:6.7. After stirring for 1 hour at 60 °C and 200 rpm, at 900 °C and 150Pa vacuum thermal activation for 3 hours , washed 7 times with deionized water, filtered, and dried at 80 °C for 3 h to obtain pretreated activated carbon;

[0064] (3) place the pretreated waste water in a closed heating container, the top of the closed heating con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com