Method for preparing ethylene sulfite by using microchannel reactor

A vinyl sulfite, micro-channel reactor technology, applied in chemical instruments and methods, chemical/physical/physical-chemical reactors, organic chemistry, etc., can solve the problem of ethylene oxide being inflammable and explosive, affecting product selectivity , the problem of high local reaction temperature, to achieve the effect of stable product quality, improved automation and safety, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

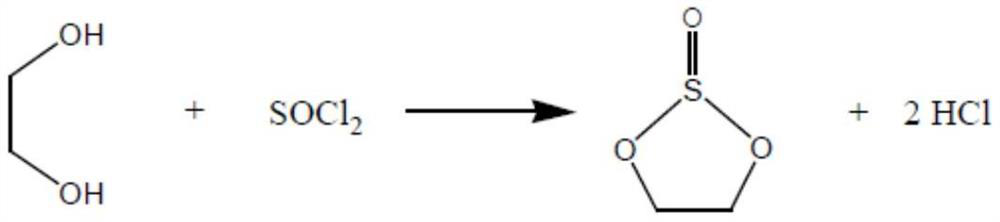

Image

Examples

Embodiment

[0017] A method for preparing vinyl sulfite in a microchannel reactor comprises mixing 10 g of ethylene glycol and 50 g of dichloromethane to form a solution; and preparing 20 g of thionyl chloride. The two feed liquids were simultaneously pumped into the microchannel reactor for reaction, the reaction temperature was controlled at 50°C, and the residence time was 60s. The effluent of the microchannel reactor was collected to obtain the crude vinyl sulfite, and the selectivity of the product was 97.89% as detected by gas chromatography. The crude vinyl sulfite is separated, and a high-purity vinyl sulfite product can be obtained through precipitation and rectification. The yield of the target product is 96%, and the content is greater than 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com