Trihydrate crystal of disodium adenosine triphosphate and preparation method thereof

A technology of adenosine triphosphate disodium trihydrate and adenosine triphosphate disodium trihydrate, which is applied in the field of medicine and can solve the problems of unfavorable industrial production and storage, complex preparation process, and low crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

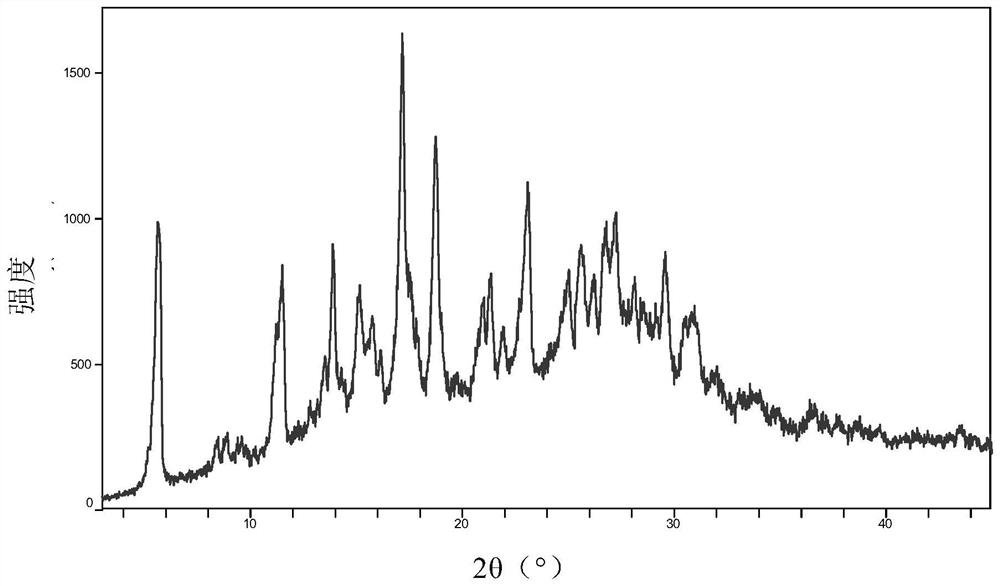

[0063] In a preferred embodiment, the crystal also has one or more X-ray powder diffraction characteristic peaks selected from the following group: 13.9°±0.2°, 27.3°±0.2°, 15.2°±0.2° , 26.8°±0.2°, 29.6°±0.2°, 21.4°±0.2°, 25.6°±0.2°, 21°±0.2°, 15.7°±0.2°, 31°±0.2°, 25°±0.2°, 30.6 °±0.2°, 26.2°±0.2°, 13.5°±0.2°, 16.2°±0.2°, 28.6°±0.2°, 33.6°±0.2°, 36.6°±0.2°, 34°±0.2°, 33.1°± 0.2°, 38.8°±0.2°, 37.2°±0.2°, 39.7°±0.2°.

[0064] In another preferred embodiment, the crystal has X-ray powder diffraction characteristic peaks selected from the following group: 17.2°±0.2°, 5.6°±0.2°, 18.7°±0.2°, 23.1°±0.2° , 11.5°±0.2°, 13.9°±0.2°, 27.3°±0.2°, 15.2°±0.2°, 26.8°±0.2°, 29.6°±0.2°, 21.4°±0.2°, 25.6°±0.2°, 21 °±0.2°, 15.7°±0.2°, 31°±0.2°, 25°±0.2°, 30.6°±0.2°, 26.2°±0.2°, 13.5°±0.2°, 16.2°±0.2°, 28.6°± 0.2°, 33.6°±0.2°, 36.6°±0.2°, 34°±0.2°, 33.1°±0.2°, 38.8°±0.2°, 37.2°±0.2°, 39.7°±0.2°.

[0065] In another preferred embodiment, the crystals have X-ray powder diffraction characteristic...

Embodiment 1

[0100] At room temperature, 2.00 g of adenosine triphosphate disodium raw material was added to 8 mL of water to prepare a 20% aqueous solution. Under stirring, 25 mL of absolute ethanol was added dropwise to the 60° C. aqueous solution, and the stirring speed was 250 rpm. After the dropwise addition, the solution was cooled to 30°C, and a solid was precipitated. After suction filtration, the filter cake was washed with about 20 mL of absolute ethanol, and dried under vacuum at 25°C to obtain 1.62 g of dry product adenosine disodium triphosphate trihydrate crystal, the total yield was 81.0%, and the purity measured by HPLC was 99.24%.

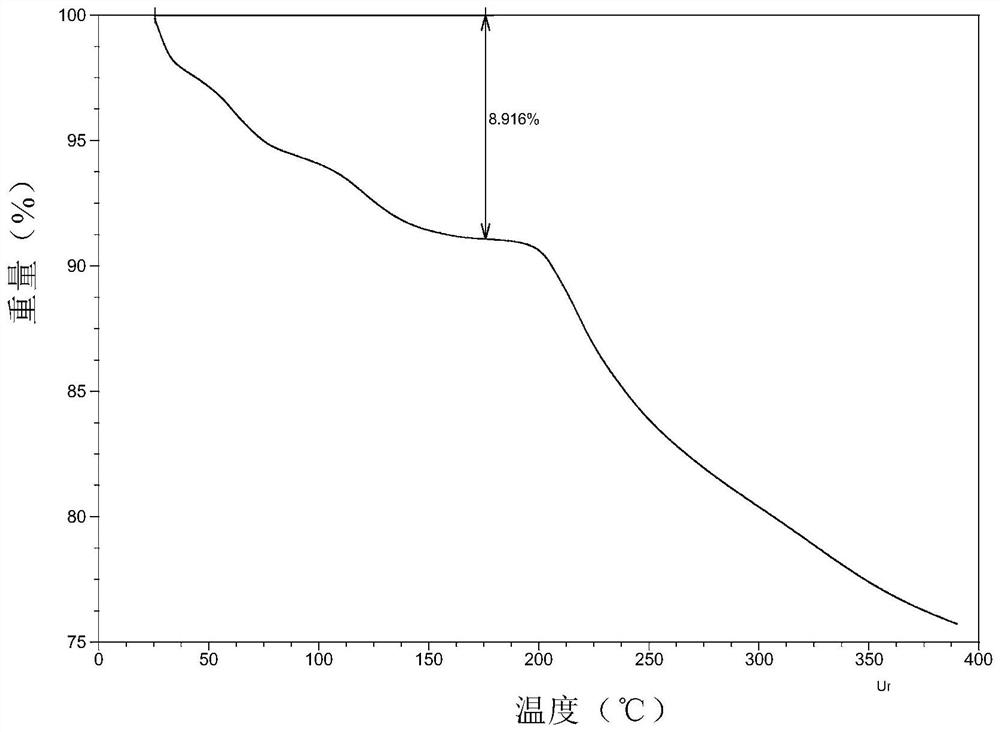

[0101] The obtained crystals of adenosine triphosphate disodium trihydrate were tested by XRPD, and the results were as follows figure 1 The spectral data are shown in Table A. TGA test was carried out on the obtained solid, and the results were as follows figure 2 As shown, the results show that in the TGA spectrum of the adenosine triphos...

Embodiment 2

[0106] At room temperature, 1.01 g of adenosine triphosphate disodium raw material was added to 9 mL of water to prepare a 10% aqueous solution. Under stirring, 10 mL of acetone was added dropwise to the 40° C. aqueous solution, and the stirring speed was 250 rpm. After the dropwise addition, the solution was cooled to 30°C, and a solid was precipitated. After suction filtration, the filter cake was washed with about 10 mL of absolute ethanol, and dried in vacuum at 25°C to obtain 0.83 g of dry product adenosine disodium triphosphate trihydrate crystal, the total yield was 82.2%, and the purity measured by HPLC was 99.52%.

[0107] The obtained crystals of adenosine disodium triphosphate trihydrate were tested by XRPD, and the results were roughly as follows figure 1 shown. TGA test was performed on the obtained solid, and the result showed that in the TGA spectrum of the adenosine triphosphate disodium trihydrate crystal, the weight loss before decomposition was 8.921%.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com