Preparation method of mixed anhydride and industrial preparation method of tauroursodeoxycholic acid dihydrate

A technology of oxycholic acid dihydrate and ursodeoxycholic acid, which is applied in the field of tauroursodeoxycholic acid synthesis, can solve the problems affecting the yield and product quality, and easy to generate impurities, so as to achieve recovery and recycling , avoid the generation of impurities, and reduce the use of solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

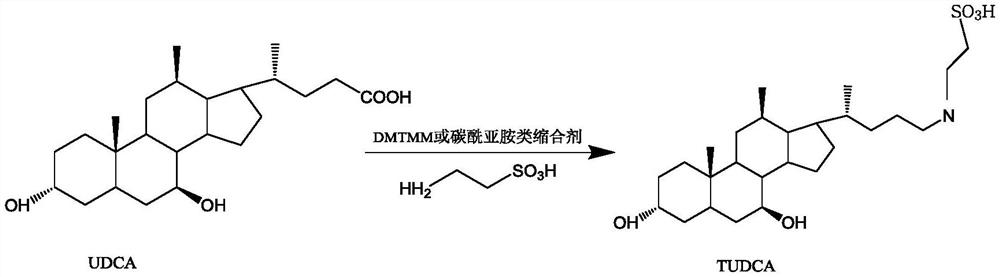

[0035] This embodiment provides a method for preparing a mixed acid anhydride, including the following steps: using ursodeoxycholic acid and alkyl chloroformate as raw materials to react in an organic solvent to generate a mixed acid anhydride, the key is that the alkyl chloroformate includes chloroformic acid Propyl and / or isopropyl chloroformate; organic solvents include propanol and / or isopropanol.

[0036] The key technical core of the present invention is: using propanol or isopropanol as the organic solvent for reaction, and using UDCA and alkyl chloroformate (formula (1)) as starting materials to prepare UDCA mixed acid anhydride. The prepared mixed acid anhydride is used for alkaline water-soluble reaction with taurine to prepare TUDCA. R in the formula (1) is propyl group or isopropyl group, and the solvent in the mixed anhydride preparation system is corresponding propanol or isopropanol (Table 1); the UDCA mixed anhydride is prepared without further treatment, and c...

specific Embodiment 2

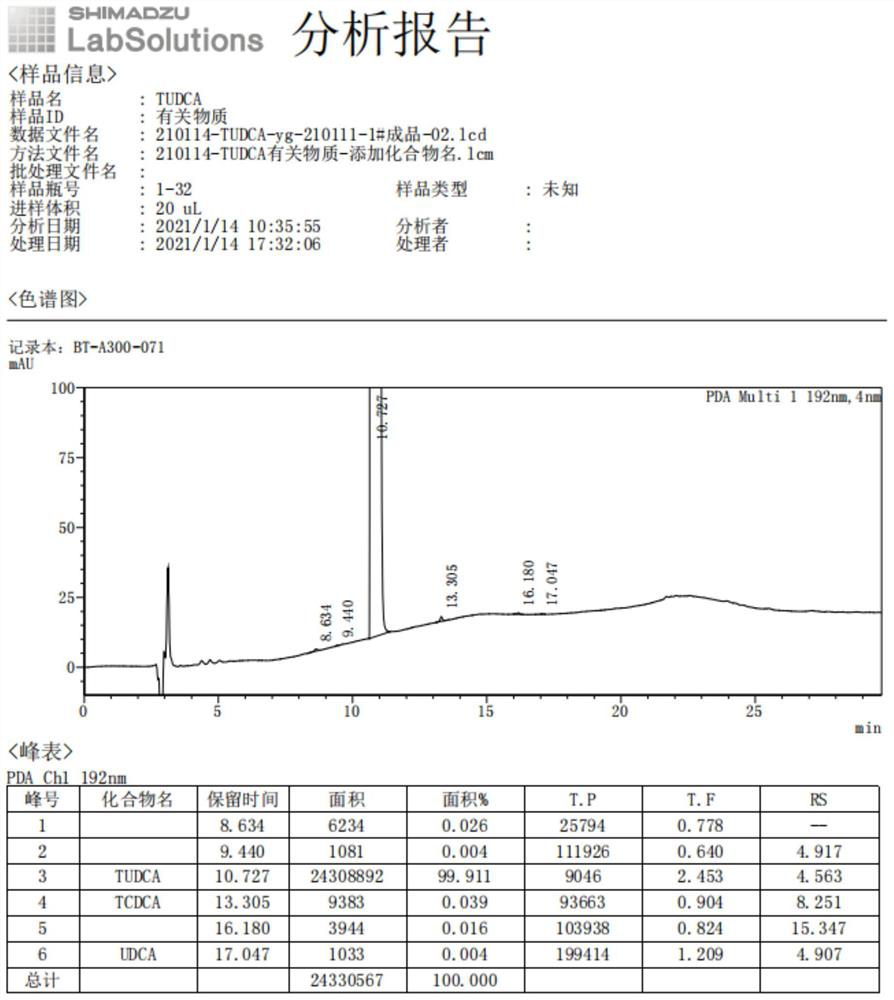

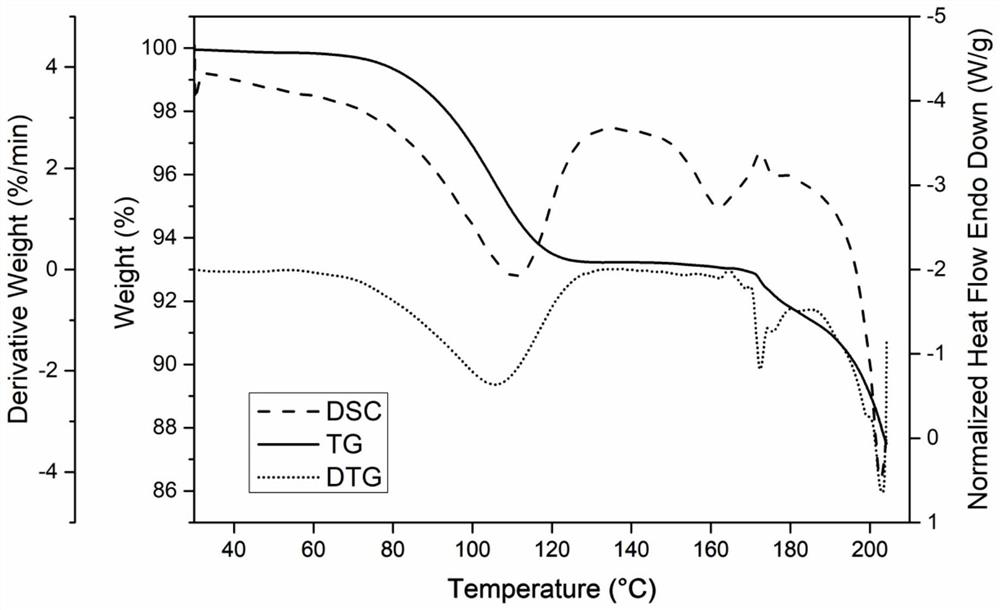

[0043] This embodiment provides a tauroursodeoxycholic acid dihydrate (TUDCA.2H) suitable for industrial production 2 O) production process, emphasizing that ursodeoxycholic acid (Ursodeoxycholic acid, UDCA) is used as the starting material, and propanol or isopropanol, propyl chloroformate or isopropyl chloroformate are used as reagents to prepare UDCA mixed acid anhydride; UDCA The mixed acid anhydride is directly reacted with sodium taurine in water to obtain the crude product of TUDCA. The crude TUDCA product is purified by water+alcohol+acetone system to obtain TUDCA dihydrate. The whole process has mild and controllable reaction, high yield and high product purity (above 99.5%). The solvent recovery is convenient, reducing the pressure on environmental protection.

[0044] TUDCA purification: The obtained crude TUDCA (more than 99%) was purified according to EP1985622A1 and JPH07267985A. The invention is further improved by adding a certain proportion of alcohol to th...

Embodiment 1

[0046] The present embodiment provides an industrialized preparation method of tauroursodeoxycholic acid dihydrate, and the specific steps are as follows:

[0047] Get UDCA 20.0kg, n-propanol 180kg and triethylamine 8kg, add in the 1000L reactor, stir, and be cooled to -10 ℃ (± 2 ℃); Slowly add propyl chloroformate 7kg, dropwise process temperature Must not exceed -5°C. After dripping, the temperature should not exceed -10°C, and the reaction of tracking UDCA was completed. Keeping the temperature, a pre-cooled aqueous solution of taurine sodium hydroxide (containing 7.5 kg of taurine, 2.6 kg of NaOH, and 80 kg of water) was added dropwise. After the dropwise addition was completed, the temperature was raised to 20-25° C. to continue the reaction until the mixed anhydride disappeared. The temperature was raised to 50°C, and the TUDCA oil was obtained by distillation under reduced pressure. Cool to 20°C (±2°C), add 80kg of pure water, stir to dissolve, add concentrated hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com