Preparation method of red direct blending dye

A direct and red technology, applied in the direction of organic dyes, azo dyes, chemical instruments and methods, etc., can solve the problems of complex components, difficult to handle, low strength, etc., and achieve superior dyeing performance, clean production promotion, and less environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a preparation method of a red direct blended dye, which comprises the following steps:

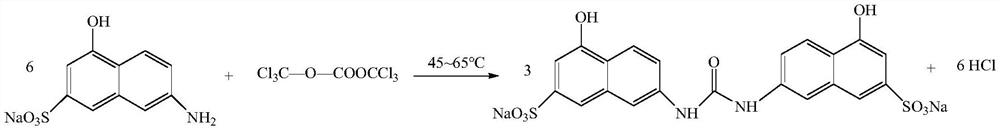

[0034] The step of obtaining scarlet acid: making the salt solution of J salt react with bis(trichloromethyl) carbonate to obtain scarlet acid reaction product, and obtain clear scarlet acid in the scarlet acid reaction product;

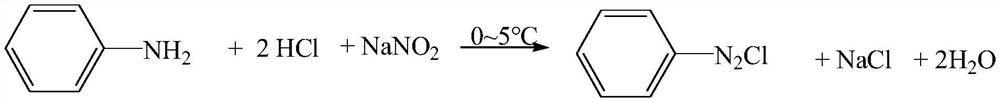

[0035] The step of obtaining diazonium salt A: making aniline carry out diazotization reaction to obtain diazonium salt A;

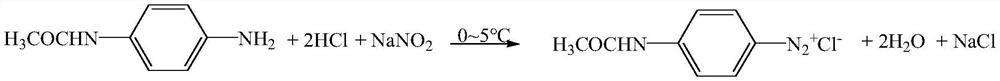

[0036] The step of obtaining diazonium salt B: making p-aminoacetanilide carry out diazotization reaction to obtain diazonium salt B;

[0037] Coupling reaction step: make clear scarlet acid and diazonium salt A and diazonium salt B carry out coupling reaction to obtain coupling product;

[0038] Post-processing step: after post-processing the coupling product, a red direct blended dye is obtained.

[0039] The red direct blended dye of the present invention has high strength and excellent dyeing performance,...

Embodiment 1

[0080] Step (1): add 600 g of bottom water to the three-necked flask, then add 85 g of J acid, start stirring, stir for 1 hour and then heat up to 45 ° C, adjust the pH to 7 with liquid caustic soda and dissolve it for later use. Add 23 g of bis(trichloromethyl) carbonate to the dissolved J salt solution, while keeping the temperature of the system at 45 °C, adjust the pH to 7 with baking soda, react for 3 hours and then raise the temperature to 55 °C to keep the pH The reaction was performed at a pH of 7 for 15 hours, then the temperature was raised to 60° C., and the reaction was maintained at a pH of 7 for 3 hours to reach the end point to obtain a scarlet acid reaction product. The scarlet acid reaction product was adjusted to pH 8 with liquid caustic soda and dissolved, then 20 g of baking soda was added, stirred for 30 min, and then closed for stirring and sedimentation. Reserve after reaching 15°C.

[0081]Step (2): Dissolve 11.5g of sodium nitrite in 35g of water, sti...

Embodiment 2

[0086] Step (1): add 600 g of bottom water to the three-necked flask and then add 85 g of J acid, turn on stirring, stir for 1 hour and then heat up to 40 ° C, adjust the pH to 6.5 with liquid caustic soda and dissolve it for later use. Add 23 g of bis(trichloromethyl) carbonate to the dissolved J acid solution, while keeping the temperature of the system at 45 °C, adjust the pH value to 5 with baking soda, react for 3 hours and then heat up to 55 °C to maintain the pH value The reaction is carried out for 5 hours for 15 hours, then the temperature is raised to 60° C., the pH value is maintained at 5, and the reaction reaches the end point after 3 hours to obtain the scarlet acid reaction product. The scarlet acid reaction product was adjusted to pH 8 with liquid caustic soda and dissolved, then 20 g of baking soda was added, stirred for 30 min, and then closed for stirring and sedimentation. Reserve after reaching 15°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com