Anti-fogging UV (ultraviolet) over-printing varnish for bathroom mirror and preparation method of anti-fogging UV over-printing varnish

A varnish and mirror technology, applied in coatings, polyurea/polyurethane coatings, epoxy resin coatings, etc., can solve the problems of user inconvenience, cumbersomeness, and long-lasting anti-fogging, etc., and achieve improved yellowing resistance Effect of changing sex, increasing durability, and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

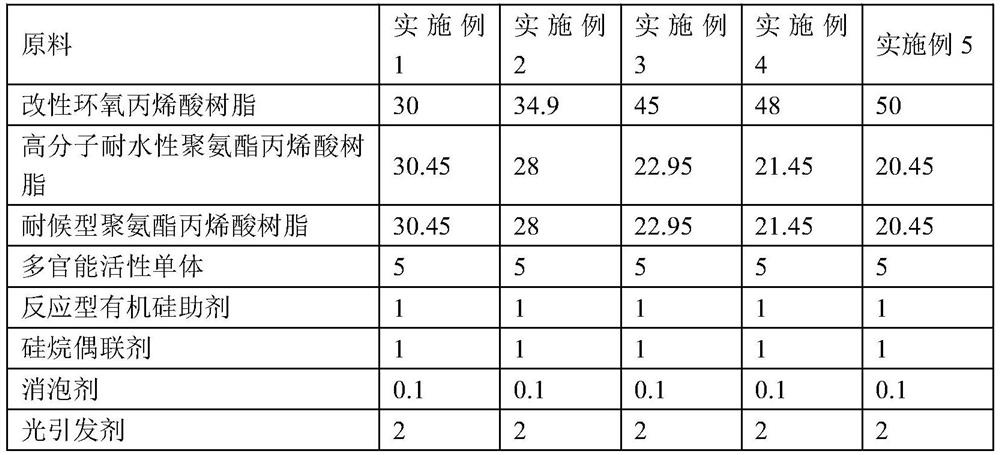

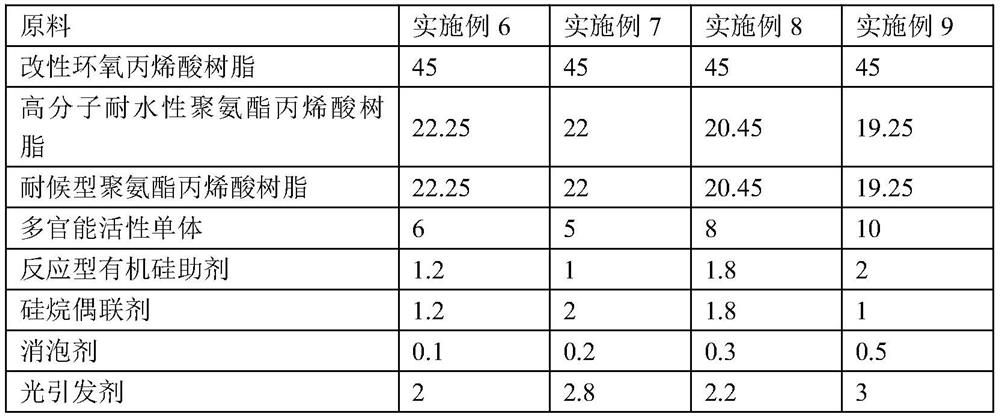

Method used

Image

Examples

preparation example 1

[0040] A kind of modified epoxy acrylic resin, it adopts following method to prepare:

[0041] The epoxy acrylic resin is heated to 82° C., triethylamine and phthalic anhydride are added and mixed, stirred for 25 minutes, and cooled to 26° C. to obtain the modified epoxy acrylic resin, wherein the weight ratio of epoxy acrylic resin, triethylamine and phthalic anhydride is is 1:0.028:0.6.

preparation example 2

[0043] A kind of modified epoxy acrylic resin, it adopts following method to prepare:

[0044] Add epoxy acrylic resin to acetone, stir for 30 minutes, then add nano-silica, stir for 15 minutes, heat to 70 ° C, and keep reacting for 4 hours to obtain modified epoxy acrylic resin, wherein acetone, epoxy acrylic resin, nano-dioxide The weight ratio of silica is 6:3:2.

preparation example 3

[0046] A kind of modified nano titanium dioxide, it adopts following method to prepare:

[0047] Put the nano titanium dioxide into absolute ethanol and mix, stir for 12min, ultrasonically disperse for 30min, add dimethyldimethoxysilane, stir for 35min, adjust the pH to 10 with 90% sodium hydroxide solution, at 80 ℃ Condensed and refluxed for 3h under the condition of 100 °C, then centrifuged, washed the solid 4 times, and dried to obtain modified nano-titanium dioxide;

[0048] Wherein, the weight ratio of nano titanium dioxide, anhydrous ethanol and dimethyldimethoxysilane is 1:8:0.3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com