Brass alloy and preparation method thereof

A brass alloy and a technology for preparation steps, applied in the field of copper alloys, can solve problems such as poor welding performance, inability to apply, and lead cannot be implemented on a large scale, and achieve the effects of excellent polishing performance, improved cutting performance, and obvious market competitive advantages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

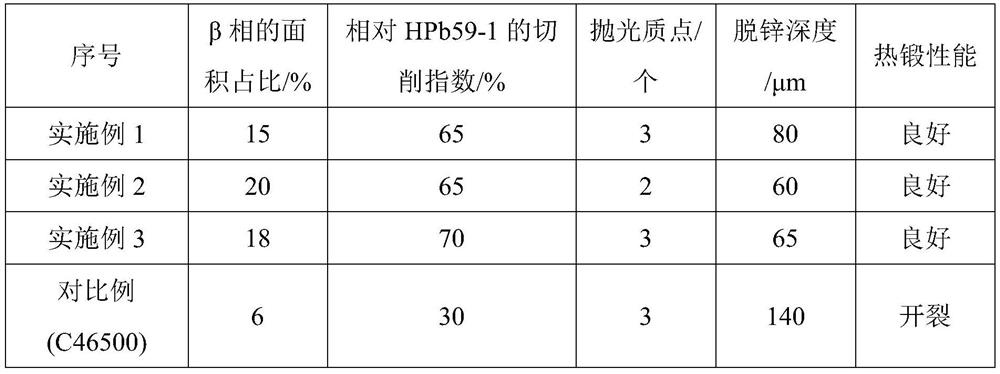

Examples

Embodiment 1

[0028] The brass alloy has a composition of 61.5wt% Cu, 0.3wt% Si, 0.6wt% Sn, 0.1wt% Pb, 0.1wt% Al, 0.1wt% As, and the balance is Zn.

[0029] The preparation steps of this brass alloy are as follows:

[0030] 1) Ingredients: Weigh Cu, Si, Sn, Pb, Al, Zn, copper-arsenic master alloy, and aluminum rare earth, wherein the copper content of the copper-arsenic master alloy is 70 wt%, and the aluminum content of aluminum rare earth is 90 wt%.

[0031] 2) Smelting: Add Cu, Si and Sn into a power frequency smelting furnace with a voltage of 380V, and perform stirring and melting. After melting, reduce the power of the smelting furnace to control the temperature at 1000-1050 ° C, and mix Pb, Al, Zn And the copper-arsenic alloy is added into the furnace to be melted, and after the above-mentioned materials are melted, they are stirred, and a brass slag cleaning agent is added, and the slag is removed by using a slag fishing tool.

[0032] 3) Composition test: Take samples in the coppe...

Embodiment 2

[0037] The brass alloy has a composition of 61.7wt% Cu, 0.35wt% Si, 0.7wt% Sn, 0.13wt% Pb, 0.1wt% Al, 0.12wt% As, and the balance is Zn.

[0038] The preparation steps of this brass alloy are as follows:

[0039] 1) Ingredients: Weigh Cu, Si, Sn, Pb, Al, Zn, copper-arsenic master alloy, and aluminum rare earth, wherein the copper content of the copper-arsenic master alloy is 70 wt%, and the aluminum content of aluminum rare earth is 90 wt%.

[0040]2) Smelting: Add Cu, Si and Sn into a power frequency smelting furnace with a voltage of 380V, and perform stirring and melting. After melting, reduce the power of the smelting furnace to control the temperature at 1000-1050 ° C, and mix Pb, Al, Zn And copper-arsenic alloy is added into the furnace for melting. After the above materials are melted, stirring is carried out and a brass slag cleaning agent is added, and the slag is removed by using a slag fishing tool.

[0041] 3) Composition test: Take samples in the copper water to ...

Embodiment 3

[0046] The brass alloy has a composition of 62.5wt% Cu, 0.2wt% Si, 0.6wt% Sn, 0.1wt% Pb, 0.1wt% Al, 0.1wt% As, and the balance is Zn.

[0047] The preparation steps of this brass alloy are as follows:

[0048] 1) Ingredients: Weigh Cu, Si, Sn, Pb, Al, Zn, copper-arsenic master alloy and aluminum rare earth, wherein the copper content of the copper-arsenic master alloy is 70wt%, and the aluminum content of aluminum rare earth is 90wt%.

[0049] 2) Smelting: Add Cu, Si and Sn into a power frequency smelting furnace with a voltage of 390V, and perform stirring and melting. After melting, reduce the power of the smelting furnace to control the temperature at 1000-1050 ° C, and mix Pb, Al, Zn And copper-arsenic alloy is added into the furnace for melting. After the above materials are melted, stirring is carried out and a brass slag cleaning agent is added, and the slag is removed by using a slag fishing tool.

[0050] 3) Composition test: Take samples in the copper water to detec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap