Ultralow elastic modulus antibacterial medical tantalum alloy and preparation method thereof

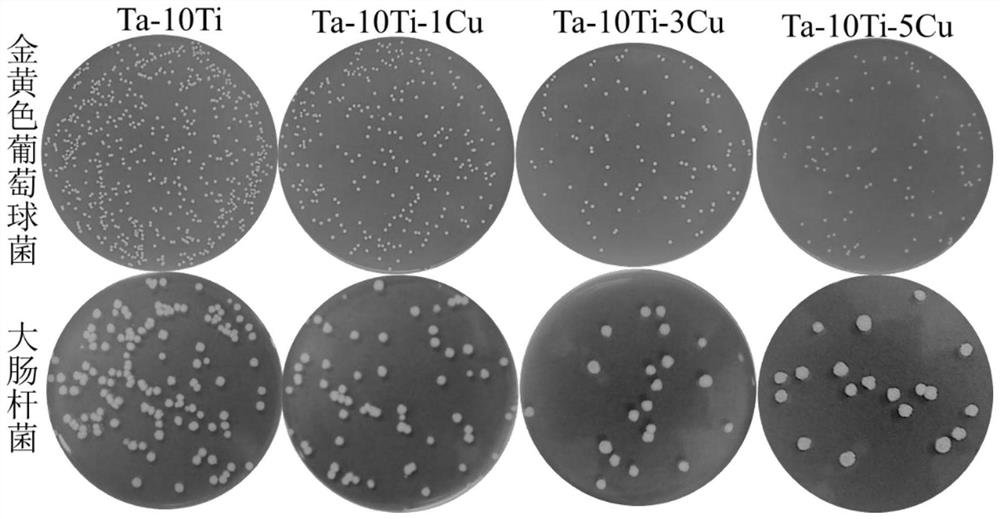

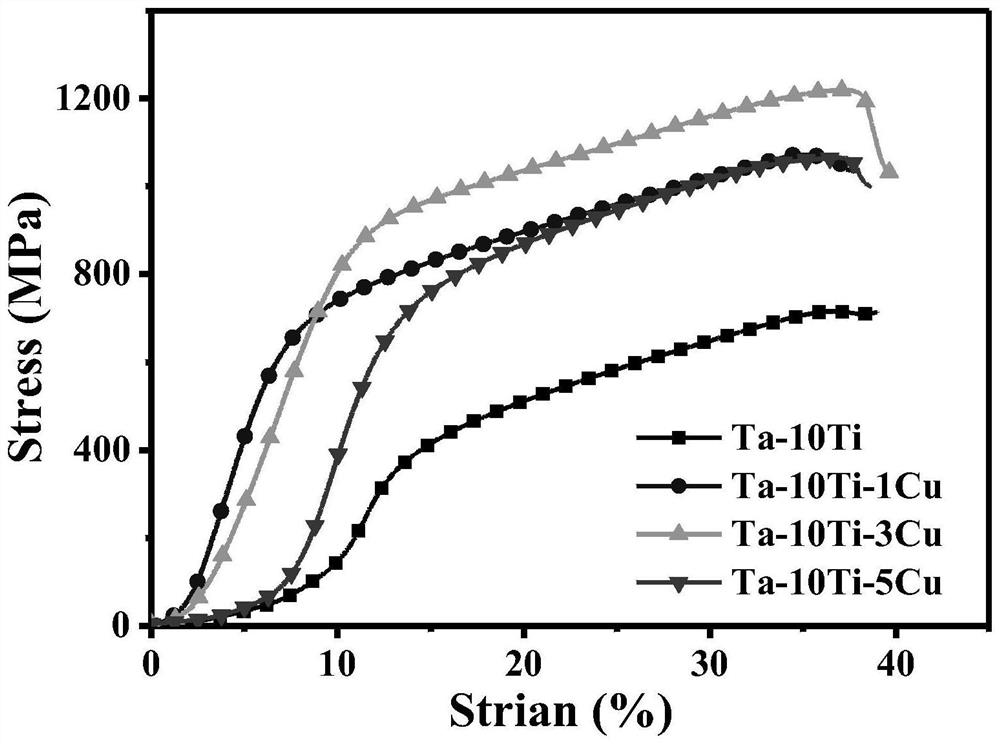

A technology of elastic modulus and tantalum alloy, which is applied in medical science, disease resistance to media transmission, prosthesis, etc., can solve the problems of frequent postoperative infection, titanium-tantalum alloy does not have antibacterial function, stress shielding effect and other problems, and achieves Long-lasting and efficient antibacterial and anti-infective properties, the effect of solving bacterial infections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1, Ta-10Ti-3Cu powder alloying

[0026] Weigh tantalum powder with a mass of about 34.8g, titanium powder with a mass of about 4.0g and copper powder with a mass of about 1.2g (the mass ratio of tantalum: titanium: copper is 87:10:3) Ball milling is carried out in a ball milling tank to obtain powder; the ball milling process parameters are the same as those in Comparative Example 1.

Embodiment 2

[0036] Embodiment 2, the preparation of Ta-10Ti-3Cu bulk alloy, the steps are as follows:

[0037] Step 1) Mechanical alloying of powders: Weigh out tantalum powder with a mass of about 34.8 g, titanium powder with a mass of about 4.0 g, and copper powder with a mass of about 1.2 g (the mass ratio of tantalum: titanium: copper is 87:10). 3) put into the ball-milling tank of inert gas protection and carry out ball-milling, obtain powder; Ball-milling process parameter is identical with embodiment 1;

[0038]Step 2) Spark plasma sintering: put the powder obtained in step 1) into a graphite mold with a diameter of 20 mm, and then put the mold into a spark plasma sintering furnace for sintering to obtain a medical tantalum alloy; sintering forming process parameters: sintering temperature: 900 ℃, pressure: 50MPa, hold for 5min. The Ta-10Ti-1Cu alloy is obtained, which is denoted as Ta-10Ti-3Cu alloy, and its density is 98% after measurement.

Embodiment 3

[0042] Example 3. Preparation of Ta-5Ti-3Cu bulk alloy. The difference between its preparation method and Example 2 is that the content of Ti added in step 1) is changed from 3% to 5%, that is, tantalum powder with a mass of about 36.8g, titanium powder with a mass of about 2.0g and Copper powder with a mass of about 1.2g (the mass ratio of tantalum:titanium:copper is 92:5:3) is obtained after the ball-milled powder is sintered by spark plasma.

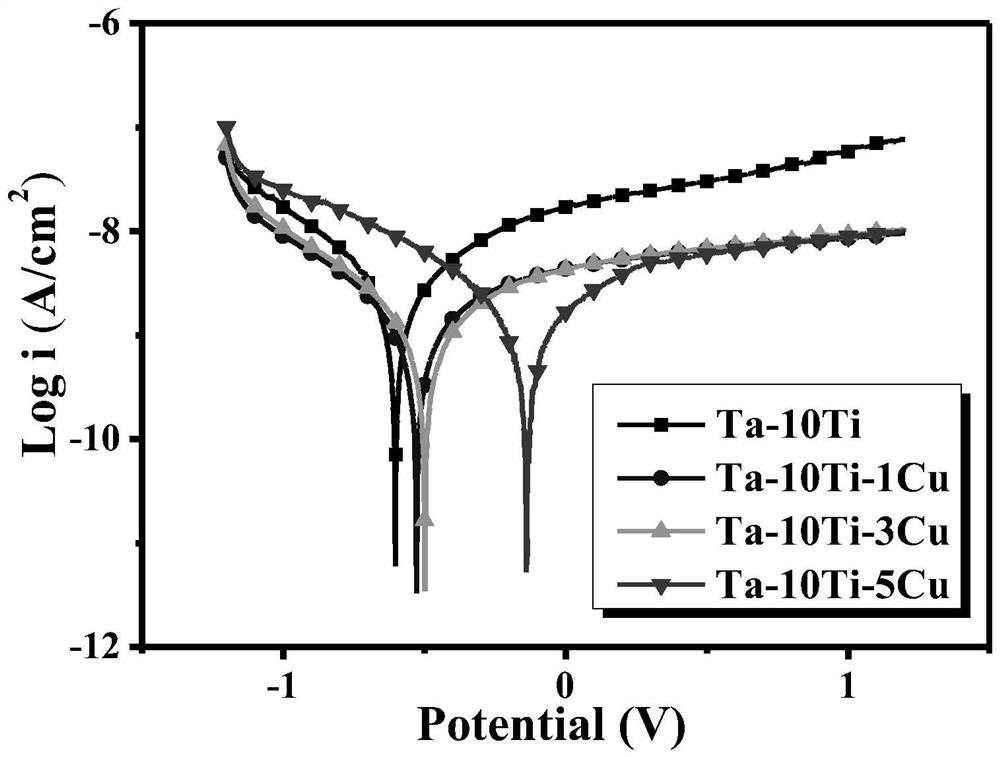

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion potential | aaaaa | aaaaa |

| Corrosion current density | aaaaa | aaaaa |

| Corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com