Preparation method of metal-based porous ceramic composite membrane

A technology of porous ceramics and porous ceramics, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve problems such as internal stress, large wall thickness, ceramic tube fracture, etc., to achieve improved mechanical strength, simple process, and good penetration sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] In order to solve the above problems in the prior art, it is imminent to develop a method for preparing a metal-ceramic composite membrane with simple process and cost saving, and it is hoped that the prepared metal-based porous ceramic composite membrane has high strength and complete membrane layer. The invention provides a method for preparing a metal-based porous ceramic composite membrane, comprising the following steps:

[0032] S1. Obtain a suspension containing ceramic powder (generally composed of ceramic powder, binder, dispersant, and solvent in proportion; the suspension containing ceramic powder can use the formula of the prior art); The suspension is coated on the porous ceramic tube 3 (single channel or multi-channel, the average pore diameter of the pores on the wall of the porous ceramic tube 3 is 0.05 ~ 5 μm; the outer diameter of the single channel porous ceramic tube is 4 ~ 50 mm, and the wall thickness is 0.2 μm. ~ 2 mm; the outer diameter of the mu...

Embodiment 1

[0045] This embodiment provides a method for preparing a metal-based porous ceramic composite membrane, comprising the following steps:

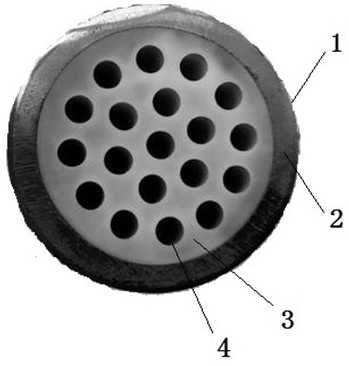

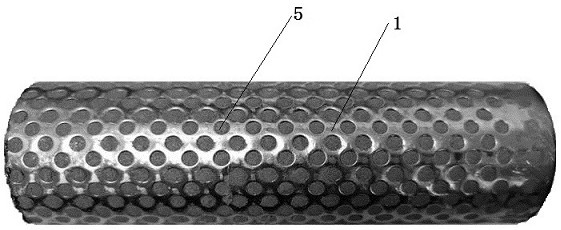

[0046] S1, obtain the suspension that comprises ceramic powder; Suspension is coated on porous ceramic tube 3 (19 passages, external diameter 31mm, cross-section opening ratio 59.8%; Porous average aperture on the porous ceramic tube 3 tube wall is 5 μm) to form a ceramic inner coating to obtain a porous ceramic tube 3 with a ceramic inner coating;

[0047] S2. Prepare the porous metal punching tube 2 (stainless steel, with an inner diameter of 36 mm and a wall thickness of 2 mm, and the hole diameter on the wall of the porous metal punching tube 2 is 3 mm), and wrap the metal wire outside the porous metal punching tube 2 Mesh 1 (stainless steel, the mesh number of hole is 200 meshes), the porous ceramic pipe 3 that has ceramic inner coating is inserted into porous metal perforated pipe 2, and an annular connector is set at one end of porous...

Embodiment 2

[0051] This embodiment provides a method for preparing a metal-based porous ceramic composite membrane, comprising the following steps:

[0052] S1, obtain the suspension that comprises ceramic powder; Suspension is coated on porous ceramic tube 3 (61 passages, external diameter 50mm, cross-sectional opening ratio 73.8%, the porous average aperture on the porous ceramic tube 3 tube wall is 3 μm) to form a ceramic inner coating to obtain a porous ceramic tube 3 with a ceramic inner coating;

[0053] S2. Prepare the porous metal punching tube 2 (stainless steel, with an inner diameter of 60 mm and a wall thickness of 2 mm, and the hole diameter on the wall of the porous metal punching tube 2 is 3 mm), and wrap the metal wire outside the porous metal punching tube 2 Mesh 1 (stainless steel, the mesh number of hole is 200 meshes), the porous ceramic pipe 3 that has ceramic inner coating is inserted into porous metal perforated pipe 2, and an annular connector is set at one end of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com