Batch production method of large-size electromagnetic shielding glass based on composite micro-nano additive manufacturing

An electromagnetic shielding and additive manufacturing technology, applied in the fields of magnetic field/electric field shielding, additive manufacturing, additive processing, etc. Shielding performance, excellent shielding performance, the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

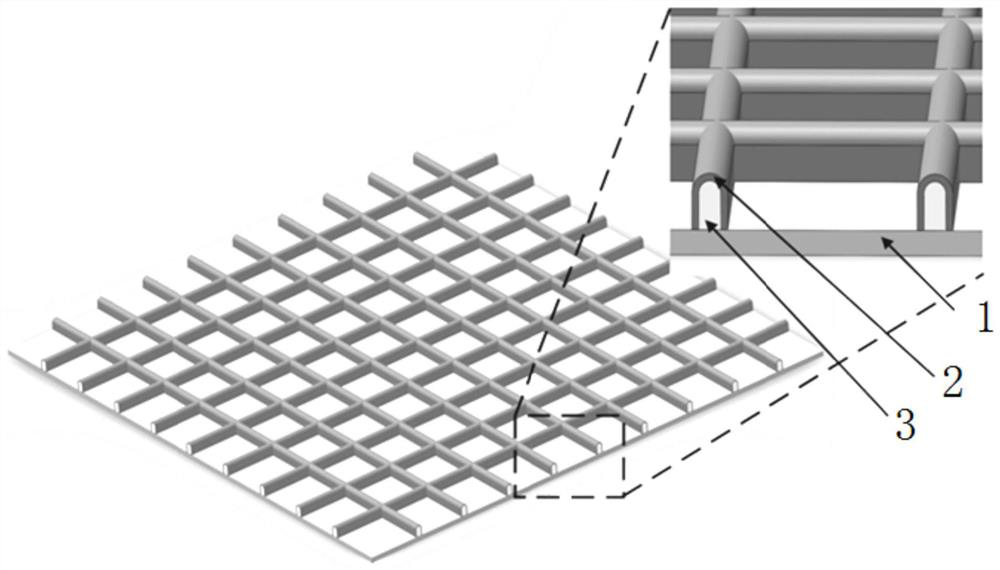

[0071] figure 1 It is a schematic diagram of a kind of Ag / Ni composite double-layer metal grid transparent electromagnetic shielding glass to be manufactured in the present invention, including: glass 1, nickel 2 and silver 3, the parameters of the Ag / Ni composite transparent electromagnetic shielding glass to be manufactured in this implementation example : Line width 7 μm, period 200 μm.

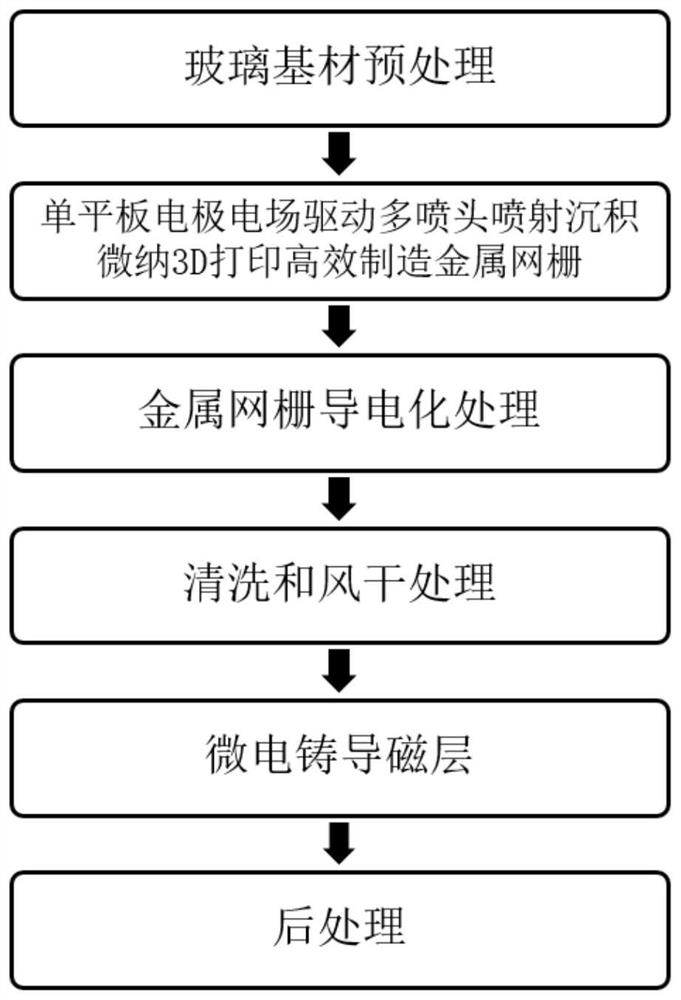

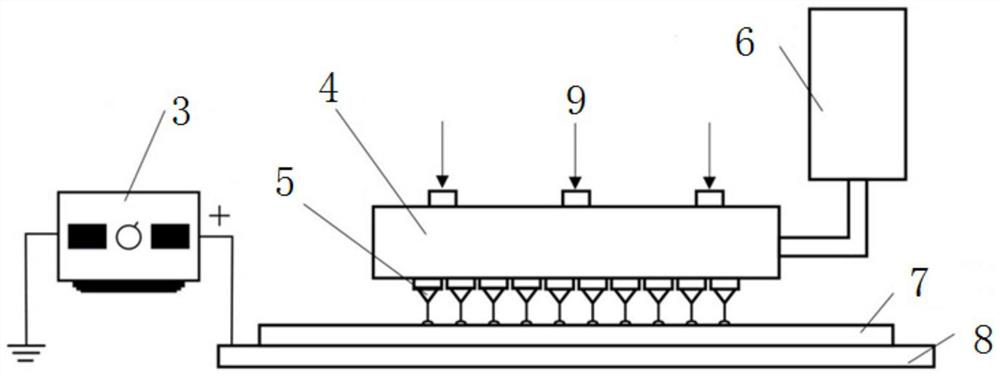

[0072] Taking the Ag / Ni composite transparent electromagnetic shielding glass described in this embodiment as an example, in combination with figure 1 , figure 2 , image 3 with Figure 4 , specifically explain the specific process of manufacturing Ag / Ni composite transparent electric shielding glass based on the method and equipment proposed in this embodiment.

[0073] S1: Pretreatment of glass substrate.

[0074] (1) Cleaning, repeatedly clean the printing substrate with deionized water to completely remove the dirt and dust on the surface.

Embodiment 2

[0100] The parameters of the copper / iron-nickel alloy composite transparent electromagnetic shielding glass to be manufactured in this implementation example: the line width is 10 μm and the period is 150 μm. The specific process of manufacturing copper / iron-nickel alloy composite transparent electric shielding glass based on the proposed method and equipment is as follows:

[0101] S1: Pretreatment of glass substrate.

[0102] (1) Cleaning, repeatedly clean the printing substrate with deionized water to completely remove impurities such as dust on the surface.

[0103] (2) Drying, and then drying in a heating oven at 70°C for 30 minutes to remove residual deionized water on the surface and ensure the cleanliness of the surface.

[0104] (3) Hydrophobic treatment. Float glass with a thickness of 2mm and a size of 400mm×400mm was selected as the printing substrate, ultrasonically cleaned with deionized water for 10 minutes, and then dried with nitrogen to ensure the cleanliness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com