Production device and production process for carbon fiber paper of hydrogen fuel cell

A carbon fiber paper and fuel cell technology, which is applied in the manufacturing of final products, sustainable manufacturing/processing, and other household appliances, etc., can solve the problems of low strength and high brittleness of carbon fiber paper, and achieves the improvement of brittleness, high strength, low strength, and improved brittleness. The degree of curing and the effect of improving the exhaust efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following is attached Figure 1-3 The application is described in further detail.

[0037] The embodiment of the present application discloses a production device and production process of hydrogen fuel cell carbon fiber paper.

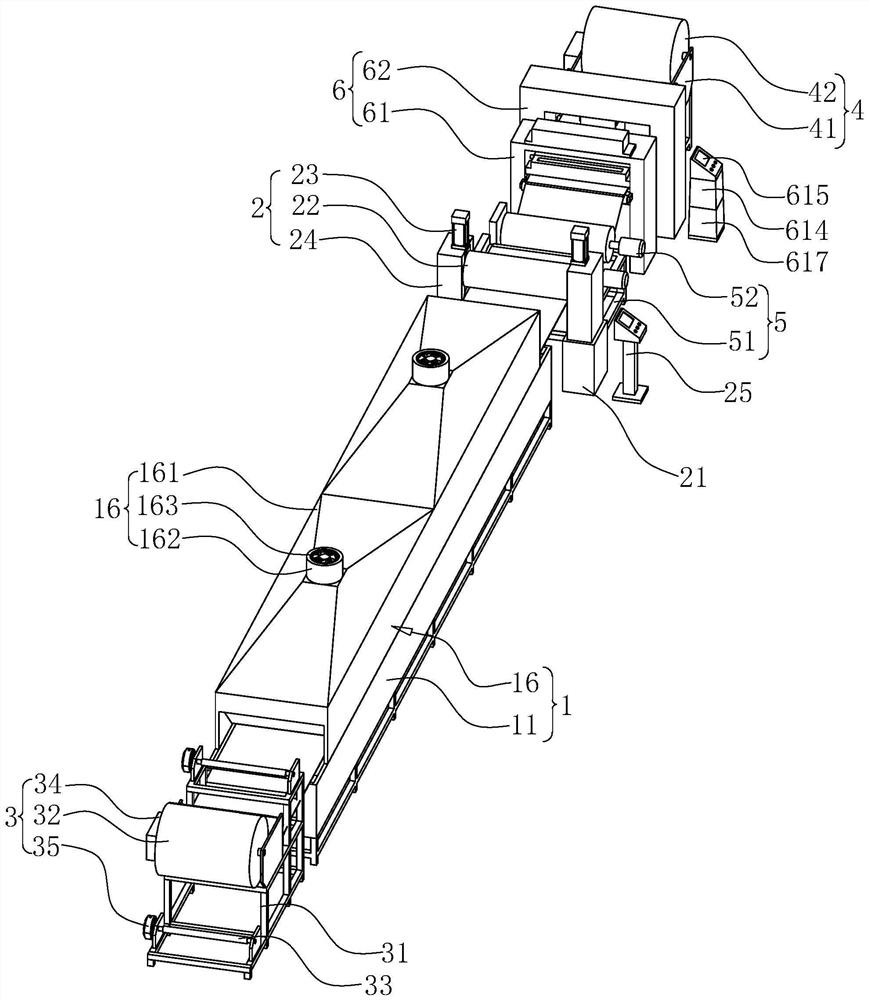

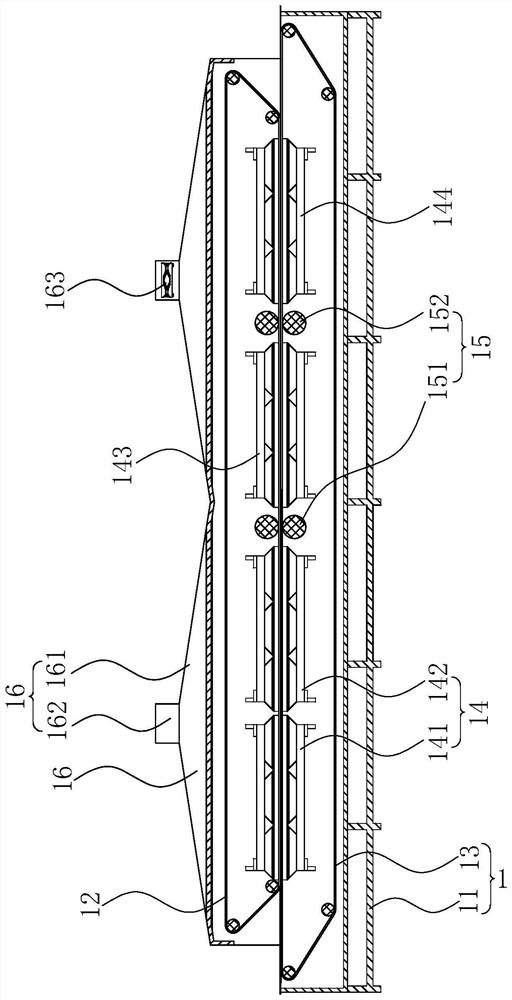

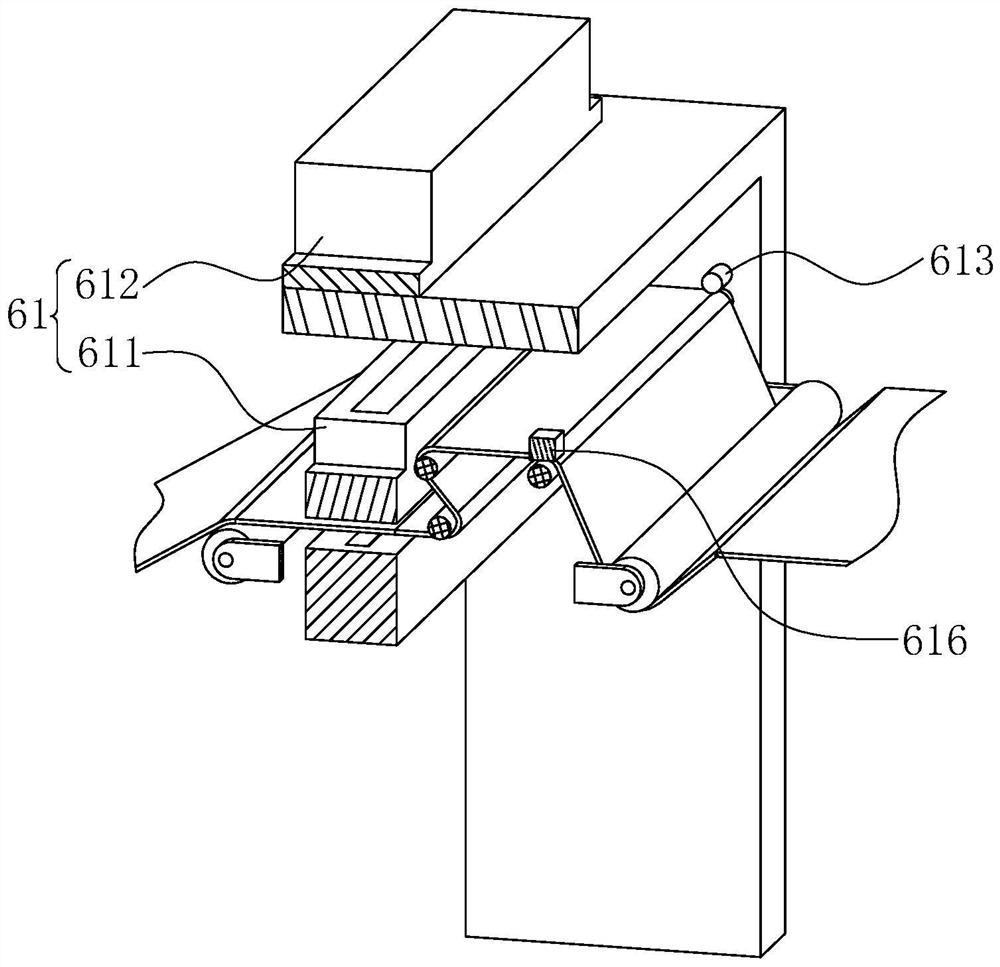

[0038] refer to figure 1 and figure 2 A hydrogen fuel cell carbon fiber paper production device and production process comprising unwinding equipment 3, curing equipment 1, hot pressing equipment 2, cooling equipment 5, testing equipment 6 and winding equipment arranged sequentially along the carbon fiber paper processing process device4.

[0039] The unwinding device 3 includes an unwinding machine base 31 fixedly placed on the ground, a plurality of magnetic powder brakes 35 fixedly installed on the side walls of the unwinding machine base 31, an unwinding machine fixedly installed on the output shaft of the magnetic powder brake 35 through a coupling. The winding roller 32 and the winding roller 33 and the tension controller 34 conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com