Preparation method of low-temperature anti-freezing emulsion polymer thickening agent for fracturing

An emulsion polymer, thickener technology, used in chemical instruments and methods, drilling compositions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

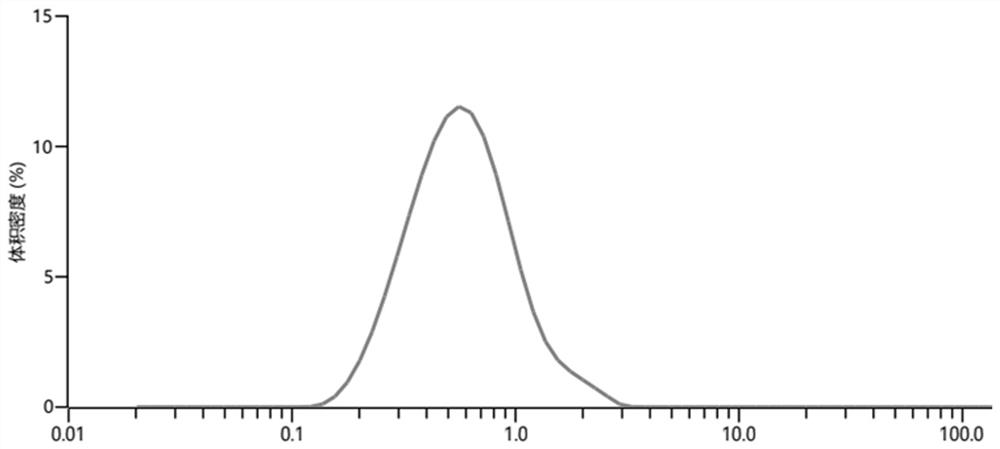

Embodiment 1

[0031] The invention provides a low-temperature antifreeze polymer emulsion thickener for fracturing, the preparation method of which is:

[0032] S1. Preparation of water phase: 20 parts by mass of acrylamide, 14 parts of acrylic acid, 5 parts of salt-resistant monomer 2-acrylamido-2-methylpropanesulfonate sodium, 0.002 parts of chain transfer agent sodium formate, chelate 0.04 part of pentasodium diethylenetriaminepentaacetic acid mixture, 0.001 part of water-soluble oxidant tert-butyl hydroperoxide, adjust the pH value to 6.2-6.5 with 9.5 parts of ammonia water, finally add 10 parts of distilled water, mix well to obtain an aqueous phase solution;

[0033] S2. Preparation of the oil phase: In the reaction kettle, according to the mass fraction ratio, 9 parts of mineral oil Exxsol D80, 17 parts of naphthenic white oil, 1.8 parts of emulsifier PEG-30 dipolyhydroxystearate, PPG-6- 0.9 parts of decyltetradeceth-12, and finally add 0.03 parts of oil-soluble initiator azobisisobu...

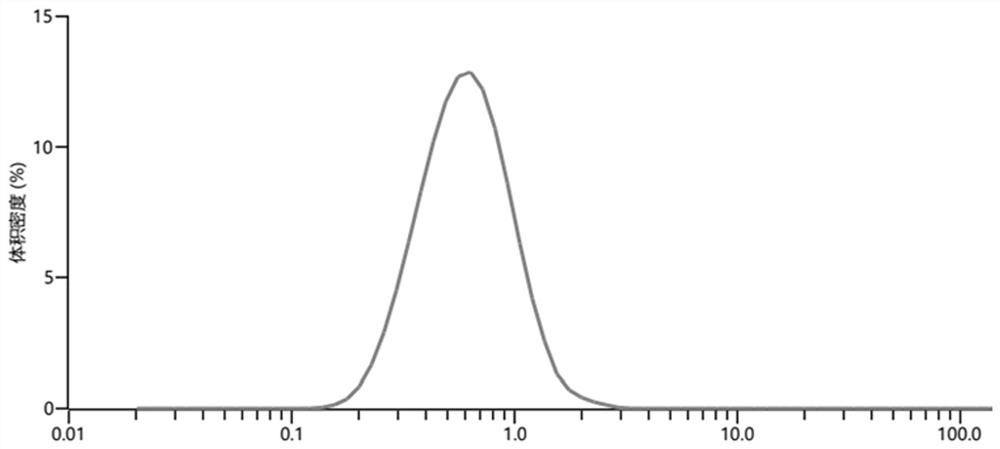

Embodiment 2

[0038] S1. Preparation of water phase: 15 parts by mass of acrylamide, 20 parts of acrylic acid, 6 parts of salt-resistant monomer 2-acrylamido-2-methylpropanesulfonate sodium, 0.002 parts of chain transfer agent sodium formate, chelate 0.04 part of pentasodium diethylenetriaminepentaacetic acid mixture, 0.001 part of water-soluble oxidant tert-butyl hydroperoxide, adjust the pH value to 6.2-6.5 with 12 parts of ammonia water, and finally add 7 parts of distilled water, mix well to obtain an aqueous phase solution;

[0039] S2. Preparation of the oil phase: In the reaction kettle, according to the mass fraction ratio, 9 parts of mineral oil Exxsol D80, 17 parts of naphthenic white oil, 1.7 parts of emulsifier PEG-30 dipolyhydroxystearate, PPG-6- 1.0 parts of decyltetradeceth-12, and finally add 0.03 parts of oil-soluble initiator azobisisobutyronitrile, and mix well to obtain a yellow transparent oil phase;

[0040] S3. Emulsification and homogeneity: the preparation process i...

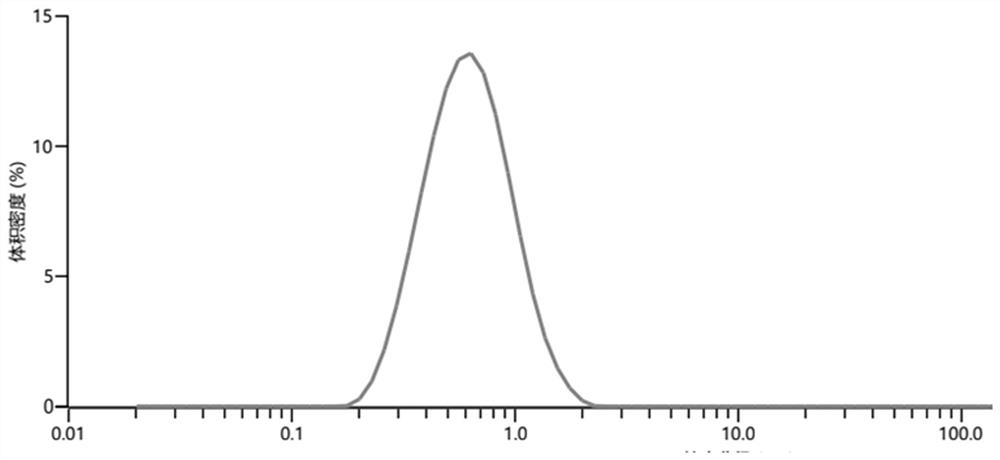

Embodiment 3

[0044] The invention provides a low-temperature antifreeze polymer emulsion thickener for fracturing, the preparation method of which is:

[0045] S1. Preparation of water phase: in parts by mass, 13 parts of acrylamide, 15 parts of acrylic acid, 6 parts of salt-resistant monomer 2-acrylamido-2-methylpropanesulfonate sodium, 0.002 parts of chain transfer agent sodium formate, chelate 0.04 part of pentasodium diethylenetriaminepentaacetic acid mixture, 0.001 part of water-soluble oxidant tert-butyl hydroperoxide, adjust the pH value to 6.2-6.5 with 10.2 parts of ammonia water, finally add 10 parts of distilled water, mix well to obtain an aqueous phase solution;

[0046] S2. Preparation of the oil phase: In the reaction kettle, according to the mass fraction ratio, 9 parts of mineral oil Exxsol D80, 17 parts of naphthenic white oil, 2.0 parts of emulsifier PEG-30 dipolyhydroxystearate, PPG-6- Decyl tetradeceth-12 0.8 parts of emulsifier, finally add 0.03 parts of oil-soluble in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brookfield viscosity | aaaaa | aaaaa |

| Pour point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com