Method and device for deoxidizing melt in converter in converter tapping process

A steel tapping process and converter technology, applied in the field of metallurgy, can solve the problems of increased heat dissipation in the molten pool, longer smelting cycle, etc., and achieve the effects of improving quality, reducing smelting blow loss, and reducing oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

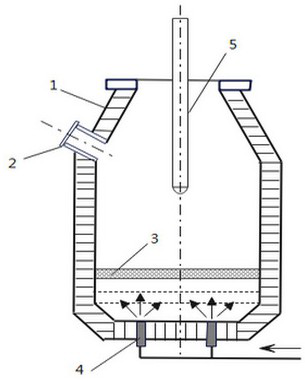

Embodiment 1

[0038] The 120-ton top-bottom combined blowing converter uses only one tapping injection element, which is buried about 450 mm directly below the tapping hole when the converter is vertical. The stirring nitrogen blown in is also used as the carrier gas for injecting carbon powder. When tapping the steel, when the tilting angle of the converter is rotated from 0° to 70° and 85°, respectively start to increase the gas flow rate (the total gas supply intensity is 0.02Nm 3 / t*min) and start toner dilute phase injection (powder gas ratio is 1.5kg / m 3 ); when the tilting angle of the tapping converter is rotated to 93° and 94°, respectively reduce and stop the carbon powder injection; when the tapping is rotated to 95°, switch to the set flow rate of the purge gas; throttle after blocking the slag at the tapping port When the proportion of steel slag in the stream increases, the furnace is lifted to stop tapping. The tapping time of the converter (the molten steel flows out from t...

Embodiment 2

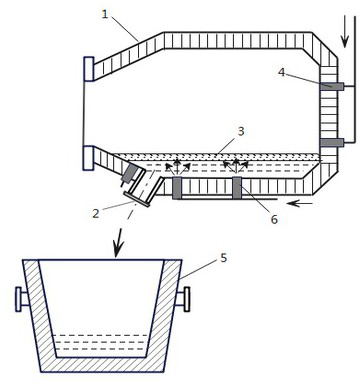

[0040] The 300-ton compound blowing converter uses three tapping injection elements, which are arranged in a row and buried in the furnace cap area directly above the tapping port when the converter is vertical, and one at about 350 mm and about 1500 mm directly below the tapping port. Spray in toner while stirring. The original process stipulates that at the end of the blowing, the oxygen blowing is stopped, and then the argon gas is blown at the bottom and stirred for 60 seconds to start shaking the furnace to tap. The embodiment of the present invention is changed to shake the furnace to start tapping after the oxygen lance is lifted out of the furnace mouth, and the smelting cycle time is correspondingly reduced. 45 seconds. The tapping blowing deoxidation process is as follows: when the tilting angle of the tapping converter is rotated from 0° to 50°, 55° and 60° at the beginning of tapping, the gas flow rate of each component is increased from bottom to top to the set va...

Embodiment 3

[0042] The 210-ton compound blowing converter uses two tapping injection elements, which are arranged in tandem and buried at about 350mm and about 1200mm directly below the tapping hole when the converter is vertical, and the gas is stirred. The original process is that at the end of blowing, the oxygen blowing lance is stopped and the furnace mouth is raised, and then the furnace is shaken to start tapping, and the melt in the stirring furnace is not deoxidized. The scheme of the embodiment: the tapping blowing deoxidation process is as follows: when the tilting angle of the tapping converter is rotated from 0° to 55° and 60° at the beginning of tapping, the gas flow rate of the two injection elements is respectively increased from the purge set value from bottom to top To the blowing set value, the air supply intensity is 0.03Nm 3 / t*min; when the tilting angle of the converter is rotated to 93° and 95°, switch the blowing flow of the two blowing elements from bottom to top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com