Shielding permanent magnet synchronous motor direct connection waterwheel type oxygenation system

A permanent magnet synchronous motor, waterwheel type technology, applied in the direction of magnetic circuit shape/style/structure, electric components, electromechanical devices, etc., can solve the problems of poor cooling effect of the motor, good oxygen increasing effect, DC motor damage, etc. Achieve the effect of prolonging the cycle of maintenance and adding water, improving heat dissipation efficiency and heat dissipation effect, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

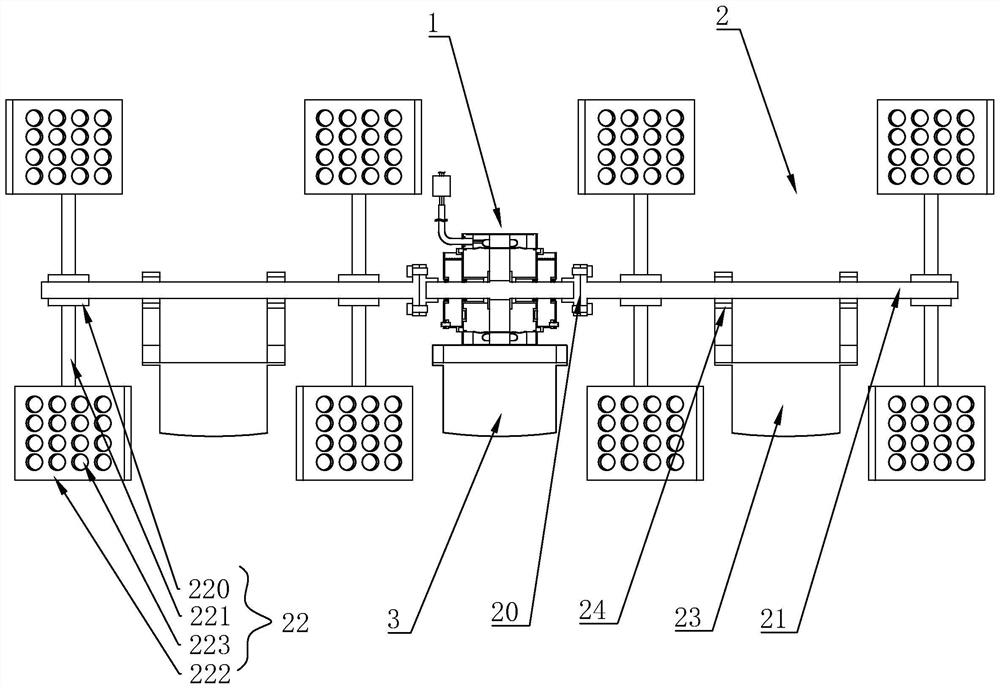

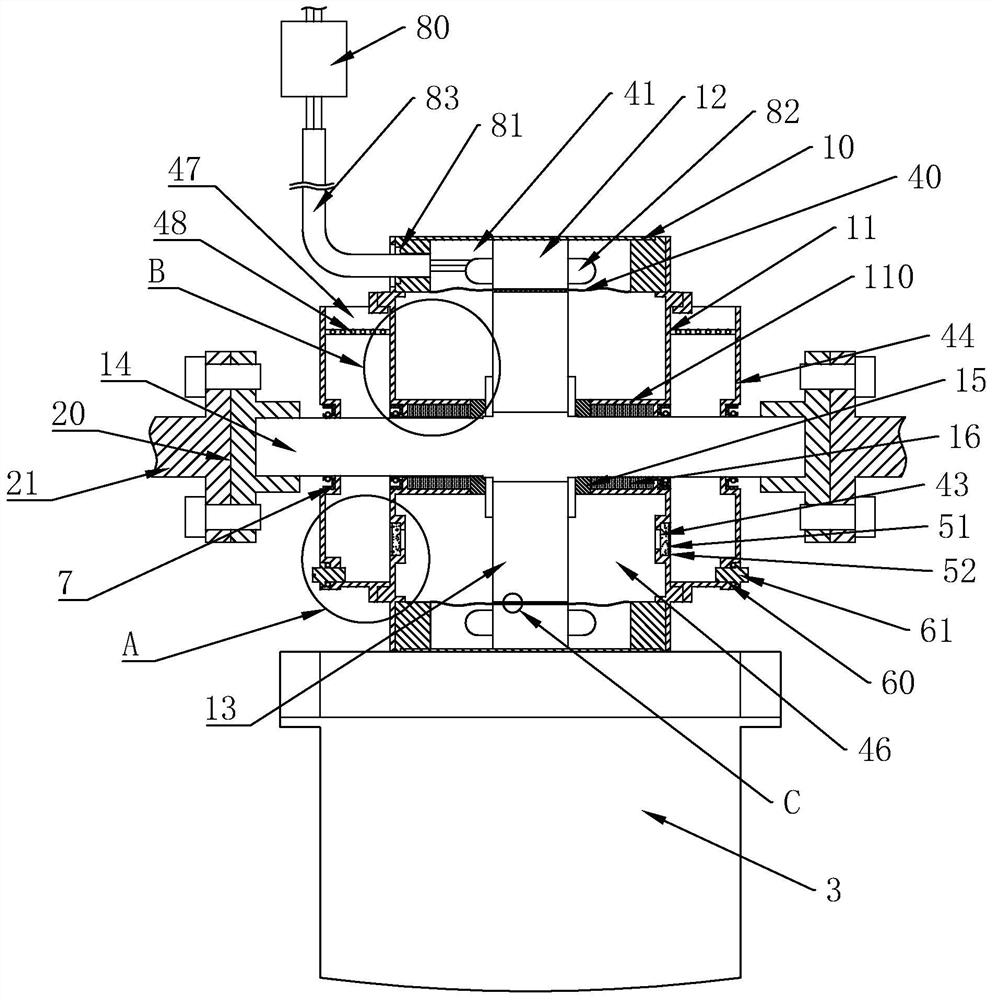

[0068] This embodiment provides a shielded permanent magnet synchronous motor 1 directly connected to the waterwheel type oxygenation system, including a motor 1, a waterwheel assembly 2 and a main pontoon 3, the motor 1 includes a casing 10, and is installed on both sides of the casing 10 The connection plate 11 at the end, the stator 12 fixed on the inner wall of the casing 10, and the rotor 13 coaxial with the stator 12 and movably connected, the rotor 13 is provided with a rotor shaft 14, and both ends of the rotor shaft 14 are connected through The disc 11 extends to the outside of the connecting disc 11, and the water wheel assembly 2 is installed at both ends of the rotor shaft 14, and also includes:

[0069] A shielding sleeve 40, the shielding sleeve 40 is installed between the two connection plates 11, and is connected with the side of the casing 10 close to the axis, and forms a shielding cavity 41 with the casing 10, the stator 12 is located in the shielding In the...

Embodiment 2

[0077] In this embodiment, in addition to including the structural features of Embodiment 1, it further includes:

[0078] A water inlet 47, the water inlet 47 is set on the top of the water storage tank 44;

[0079] A shielding frame 48, which is installed on the inner wall of the water storage tank 44 close to the water inlet 47;

[0080] Wherein, the shielding frame 48 is formed by crossing a plurality of round rods; the water storage tank 44 and the shielding frame 48 are preferably made of plastic material, and the plurality of round rods are preferably integrally formed, and preferably between the water storage tank 44 Bonding is used.

[0081] In this embodiment, it can be seen that by opening a water inlet 47 at the top of the water storage tank 44, and setting a shield frame 48 at the water inlet 47, through the operation of the water wheel assembly 2, part of the splashed water enters the water storage tank from the water inlet 47. 44, it can prolong the cycle of m...

Embodiment 3

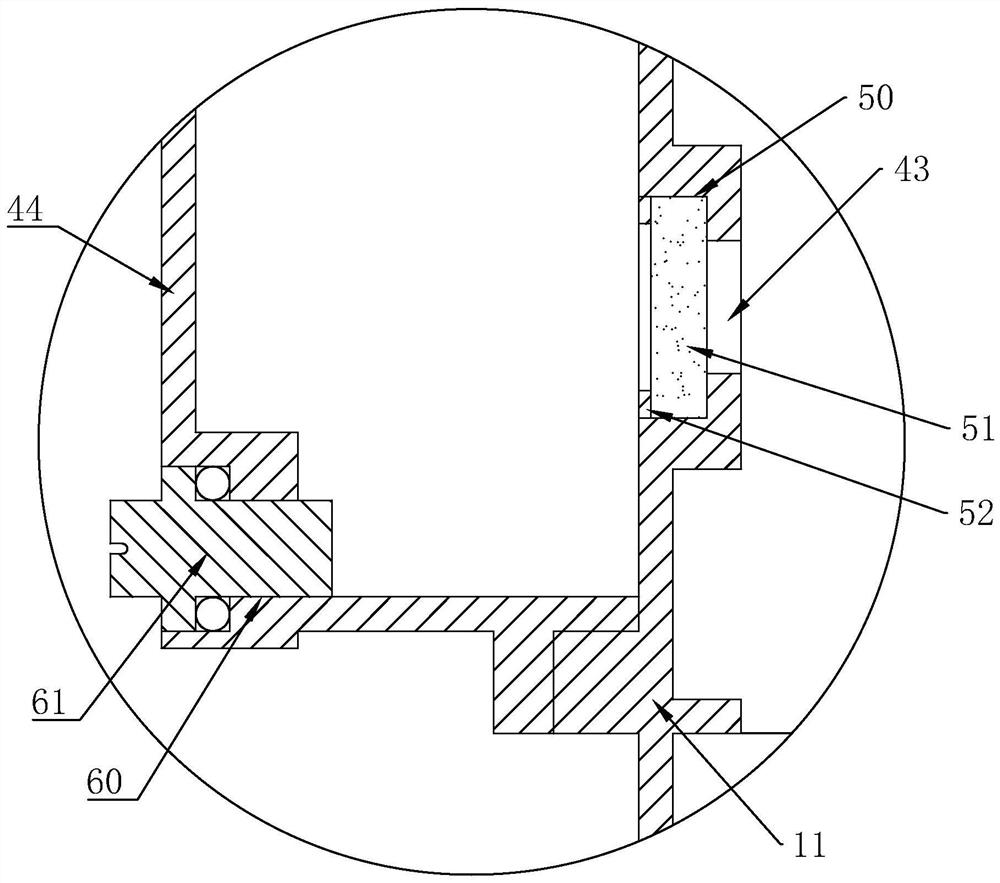

[0083] In this embodiment, in addition to including the structural features of Embodiment 2, it further includes:

[0084] The installation groove 50, the installation groove 50 is opened on the side of the connection plate 11 close to the water storage tank 44, and is coaxially arranged with the water hole 43;

[0085] Filter cotton 51, the filter cotton 51 is installed in the installation groove 50;

[0086] A retaining ring 52, the retaining ring 52 is detachably connected to the inner wall of the installation groove 50, and is used to install the filter cotton 51 in the installation groove 50;

[0087] Wherein, the retaining ring 52 and the inner wall of the installation groove 50 are preferably clamped, and interference fit or threaded connection may also be used.

[0088] It can be seen from this embodiment that by setting the filter cotton 51 at the water hole 43, the water entering the water storage chamber 46 and the water gap 45 can be filtered, thereby preventing i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com