Antibacterial dentin adhesive and preparation method thereof

A technology of adhesives and dentin, applied in dental preparations, dentistry, pharmaceutical formulations, etc., to achieve the effect of controllable particle size and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

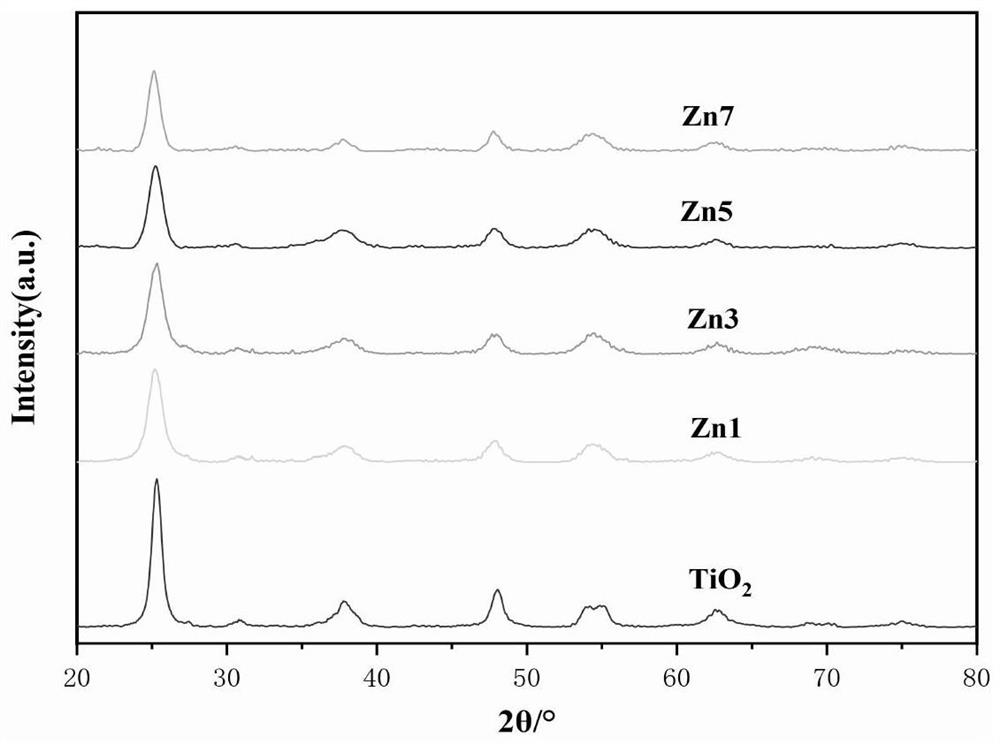

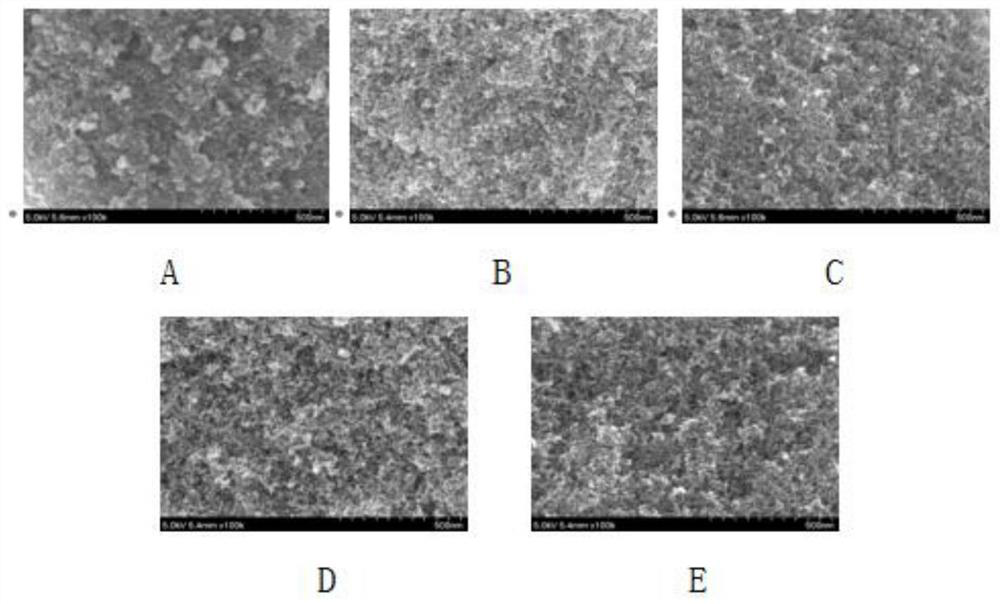

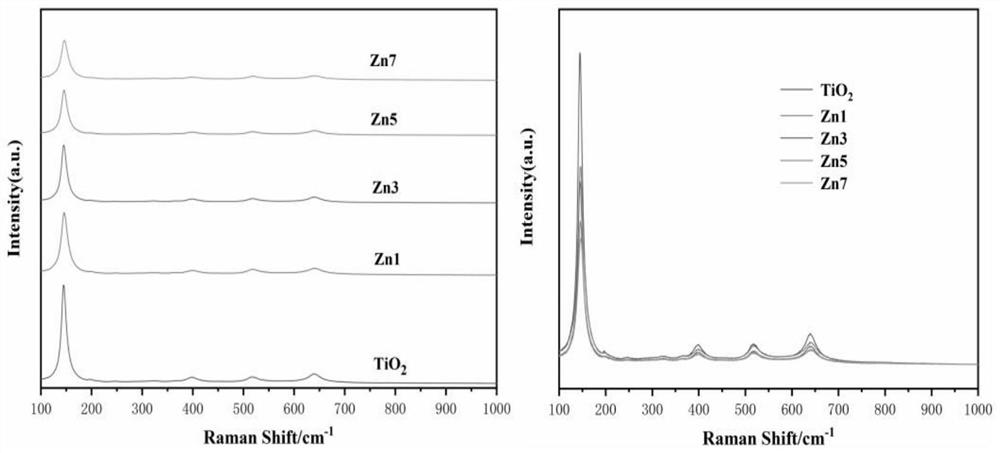

Method used

Image

Examples

Embodiment 1

[0055] (1) Preparation of solution A: add 5 mL of tetrabutyl titanate and 5 mL of absolute ethanol into the dropper respectively;

[0056] (2) Preparation of solution B: 20 mL of absolute ethanol, 5 mL of deionized water, 1 mL of concentrated nitric acid, 0.0130 mL of ammonia water, 0.1224 mL of zinc nitrate hexahydrate [Zn(NO 3 ) 2 6(H 2 O)] are added in the beaker respectively;

[0057] (3) Add solution A into solution B at a constant rate of 1 drop (0.25ml / min) every 2 seconds, and stir at the same time (rotation speed is 500r / min), and continue to stir after dropping (rotation speed is 500r / min) 2h, a pale yellow transparent sol was obtained;

[0058] (4) The obtained sol was transferred to a hydrothermal kettle, heated at 160° C. for 6h in an electric heating blast drying oven; after the reaction, it was placed in an ultrasonic cleaner and ultrasonically cleaned with absolute ethanol (ultrasonic cleaning power was 150w), and the reaction was carried out at 8000r Cen...

Embodiment 2

[0070] (1) Preparation of solution A: add 5 mL of tetrabutyl titanate and 5 mL of absolute ethanol into the dropper respectively;

[0071] (2) Preparation of solution B: 20 mL of absolute ethanol, 5 mL of deionized water, 1 mL of concentrated nitric acid, 0.014 mL of ammonia water, 0.1311 mL of zinc nitrate hexahydrate [Zn(NO 3 ) 2 6(H 2 O)] are added in the beaker respectively;

[0072] (3) Add solution A into solution B at a constant rate of 1 drop (0.25ml / min) every 2 seconds, and stir at the same time (rotation speed is 500r / min), and continue to stir after dropping (rotation speed is 500r / min) 2h, a pale yellow transparent sol was obtained;

[0073] (4) The obtained sol was transferred to a hydrothermal kettle, heated at 160° C. for 6h in an electric heating blast drying oven; after the reaction, it was placed in an ultrasonic cleaner and ultrasonically cleaned with absolute ethanol (ultrasonic cleaning power was 150w), and the reaction was carried out at 8000r Cent...

Embodiment 3

[0085] (1) Preparation of solution A: add 5 mL of tetrabutyl titanate and 5 mL of absolute ethanol into the dropper respectively;

[0086] (2) Preparation of solution B: 20 mL of absolute ethanol, 5 mL of deionized water, 1 mL of concentrated nitric acid, 0.0149 mL of ammonia water, 0.1398 mL of zinc nitrate hexahydrate [Zn(NO 3 ) 2 6(H 2 O)] are added in the beaker respectively;

[0087] (3) Add solution A into solution B at a constant rate of 1 drop (0.25ml / min) every 2 seconds, and stir at the same time (rotation speed is 500r / min), and continue to stir after dropping (rotation speed is 500r / min) 2h, a pale yellow transparent sol was obtained;

[0088] (4) The obtained sol was transferred to a hydrothermal kettle, heated at 160° C. for 6h in an electric heating blast drying oven; after the reaction, it was placed in an ultrasonic cleaner and ultrasonically cleaned with absolute ethanol (ultrasonic cleaning power was 150w), and the reaction was carried out at 8000r Cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com