Water-based antifouling treatment agent

An antifouling, water-based technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of high curing temperature, inconvenient construction, high price, poor adhesion, etc., achieve excellent antifouling performance, improve compatibility The effect of low resistance and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

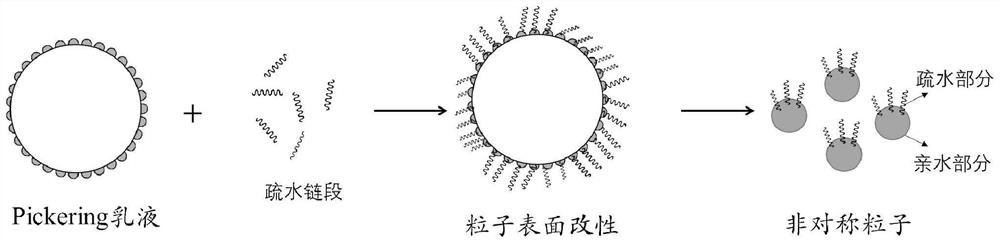

[0024] Asymmetric Amphiphilic Nanoparticle Synthesis

[0025] S1. At room temperature, take 1g of SiO 2 Nanoparticles were added to 20 mL of deionized water, and ultrasonically dispersed for 30 min. Stir and heat to 75°C, then add 10 g of paraffin, and after the paraffin is melted, homogeneously emulsify at high speed. After cooling to below 25°C, a Pickering emulsion was obtained.

[0026] S2. Disperse 0.2 g of butyltrimethoxysilane in methanol solution, add it into the Pickering emulsion of silica, continue stirring, add a small amount of ammonia water for catalysis, and maintain the reaction for 24 hours. The surface of the nanoparticles on the paraffin surface is modified by silylation to obtain nanoparticles with asymmetric structure.

[0027] S3, post-processing: the modified asymmetric structure nanoparticles are carried out. After the reaction is completed, the paraffin balls after the reaction are dissolved by using a solvent, centrifuged, washed with absolute eth...

Embodiment 2

[0030] Asymmetric Amphiphilic Nanoparticle Synthesis

[0031] S1. At room temperature, take 2g of TiO 2 Nanoparticles were added to 20 mL of deionized water, and ultrasonically dispersed for 30 min. Stir and heat to 75°C, then add 15 g of paraffin, and after the paraffin is melted, homogeneously emulsify at high speed. After cooling to below 25°C, a Pickering emulsion was obtained.

[0032] S2. Disperse 1 g of (3,3,3-trifluoropropyl)methyldimethoxysilane in methanol solution, add it to the Pickering emulsion of titanium dioxide, continue stirring, add a small amount of ammonia for catalysis, and maintain the reaction for 24h. The surface of the nanoparticles on the paraffin surface is modified by silylation to obtain nanoparticles with asymmetric structure.

[0033] S3, post-processing: the modified asymmetric structure nanoparticles are carried out. After the reaction is completed, the paraffin balls after the reaction are dissolved by using a solvent, centrifuged, washed...

Embodiment 3~6

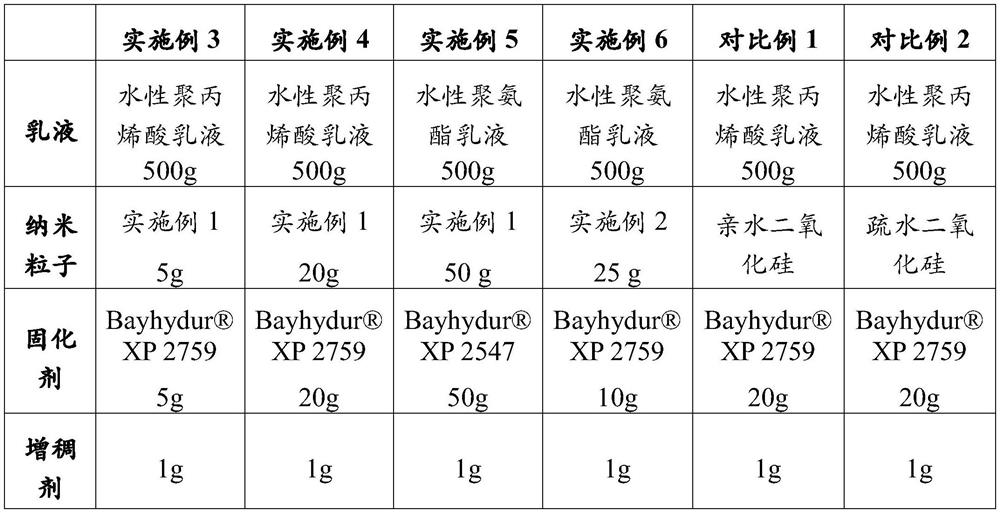

[0036] Synthesis of water-based antifouling treatment agent

[0037] The proportions of Examples 3 to 6 and Comparative Examples 1 to 2 are shown in Table 1. After mixing the components in proportion, they were uniformly coated on the PU leather and cured at 130° C. for 10 minutes. Test surface tension (water drop angle), adhesion, as shown in Table 2.

[0038] Table 1

[0039]

[0040]

[0041] The above-mentioned thickener is a nonionic hydrophobically modified polyurethane rheological thickener, and the defoamer is a silicone defoamer.

[0042] Table 2

[0043]

[0044] The test results show that the water-based antifouling treatment agent made of asymmetric amphiphilic nanoparticles has high contact angle and good adhesion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com