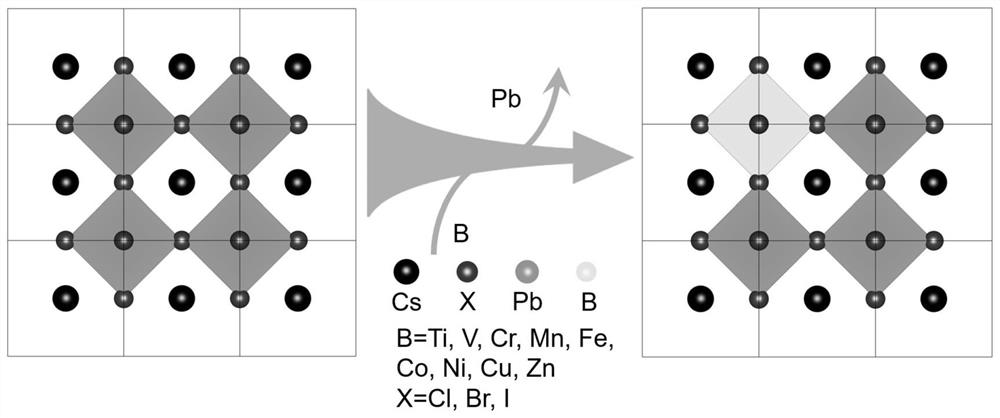

Transition metal ion doped perovskite quantum dot material and preparation method thereof

A quantum dot material, transition metal technology, applied in luminescent materials, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve the problems of unstable crystal structure of all-inorganic perovskite quantum dot materials, etc. To achieve the effect of simple and efficient adjustment of reaction parameters, excellent luminescence performance, and improved water stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

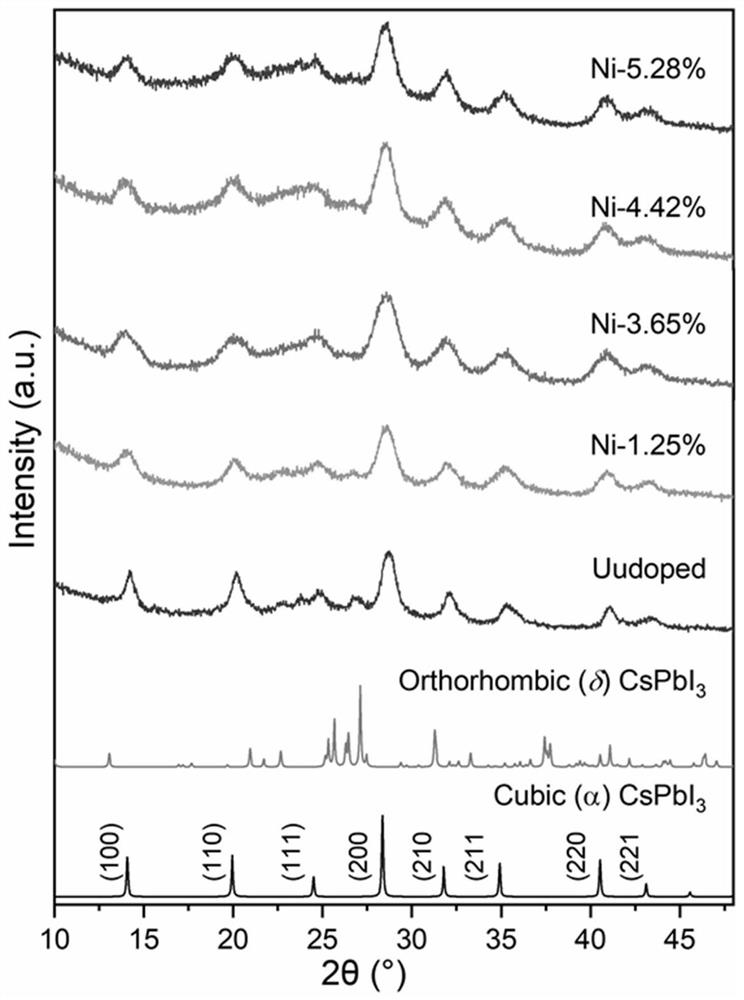

Embodiment 1

[0060] This embodiment provides a perovskite quantum dot material, and the preparation method includes the following steps:

[0061] (1) Preparation of cesium oleate precursor solution; 0.2g of cesium carbonate, 0.7ml of oleic acid and 10ml of 1-octadecene were weighed and put into a 25ml three-necked flask, and after vacuum drying at 120 ° C for 1h, under an inert gas environment Heating to 150℃, after the cesium carbonate is completely dissolved, adjust the temperature back to 120℃ for subsequent use;

[0062] (2) prepare the mixed solution of lead iodide and nickel iodide: 92.2mg lead iodide and 62.5mg nickel iodide are weighed and loaded into a 25ml three-necked flask, and 5ml 1-octadecene and 1ml tri-n-octyl are added Phosphine, after vacuum drying at 120 °C for 1 h, inject 1 ml of dry oleylamine and oleic acid respectively, and heat the solution to 170 °C under an inert atmosphere when the solution is clear and transparent;

[0063] (3) take 0.4ml of the cesium oleate p...

Embodiment 2

[0067] This embodiment provides a perovskite quantum dot material, and the preparation method includes the following steps:

[0068] (1) Preparation of cesium oleate precursor solution; 0.2g of cesium carbonate, 0.7ml of oleic acid and 10ml of 1-octadecene were weighed and put into a 25ml three-necked flask, and after vacuum drying at 120 ° C for 1h, under an inert gas environment Heating to 150℃, after the cesium carbonate is completely dissolved, adjust the temperature back to 120℃ for subsequent use;

[0069] (2) prepare the mixed solution of lead iodide and nickel iodide: 92.2mg lead iodide and 187.5mg nickel iodide are weighed and loaded into a 25ml three-necked flask, and 5ml 1-octadecene and 1ml tri-n-octyl are added Phosphine, after vacuum drying at 120 °C for 1 h, inject 1 ml of dry oleylamine and oleic acid respectively, and heat the solution to 170 °C under an inert atmosphere when the solution is clear and transparent;

[0070] (3) take 0.4ml of the cesium oleate ...

Embodiment 3

[0074] This embodiment provides a perovskite quantum dot material, and the preparation method includes the following steps:

[0075] (1) Preparation of cesium oleate precursor solution; 0.2g of cesium carbonate, 0.7ml of oleic acid and 10ml of 1-octadecene were weighed and put into a 25ml three-necked flask, and after vacuum drying at 120 ° C for 1h, under an inert gas environment Heating to 150℃, after the cesium carbonate is completely dissolved, adjust the temperature back to 120℃ for subsequent use;

[0076] (2) prepare the mixed solution of lead iodide and nickel iodide: 92.2mg lead iodide and 187.5mg nickel iodide are weighed and loaded into a 25ml three-necked flask, and 5ml 1-octadecene and 1ml tri-n-octyl are added Phosphine, after vacuum drying at 120 °C for 1 h, inject 1 ml of dry oleylamine and oleic acid respectively, and heat the solution to 185 °C under an inert atmosphere when the solution is clear and transparent;

[0077] (3) take 0.4ml of the cesium oleate ...

PUM

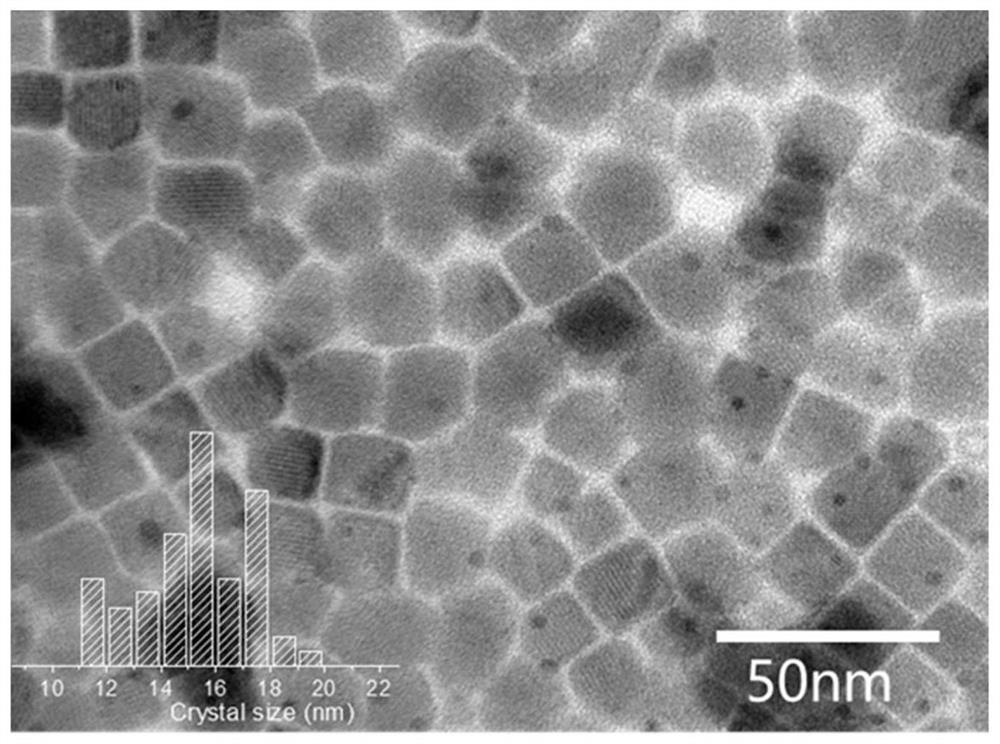

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com