A kind of preparation method of samarium cobalt base nanocrystalline permanent magnet material

A permanent magnet, samarium-cobalt technology, applied in the field of preparation of new samarium-cobalt-based nanocrystalline permanent magnets, can solve the problems of difficult control of nanocrystal size, quantity and distribution, high alloy manufacturing cost, and long preparation cycle , to achieve the effects of controlling the uniformity of the grain, enhancing the stability of the crystal structure, increasing the coercive force and saturation magnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

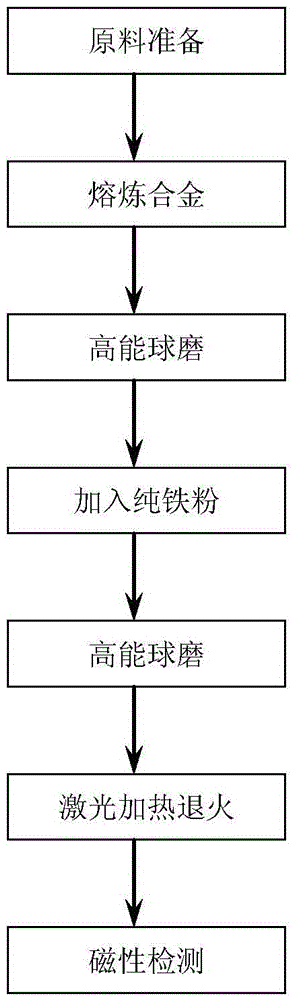

Method used

Image

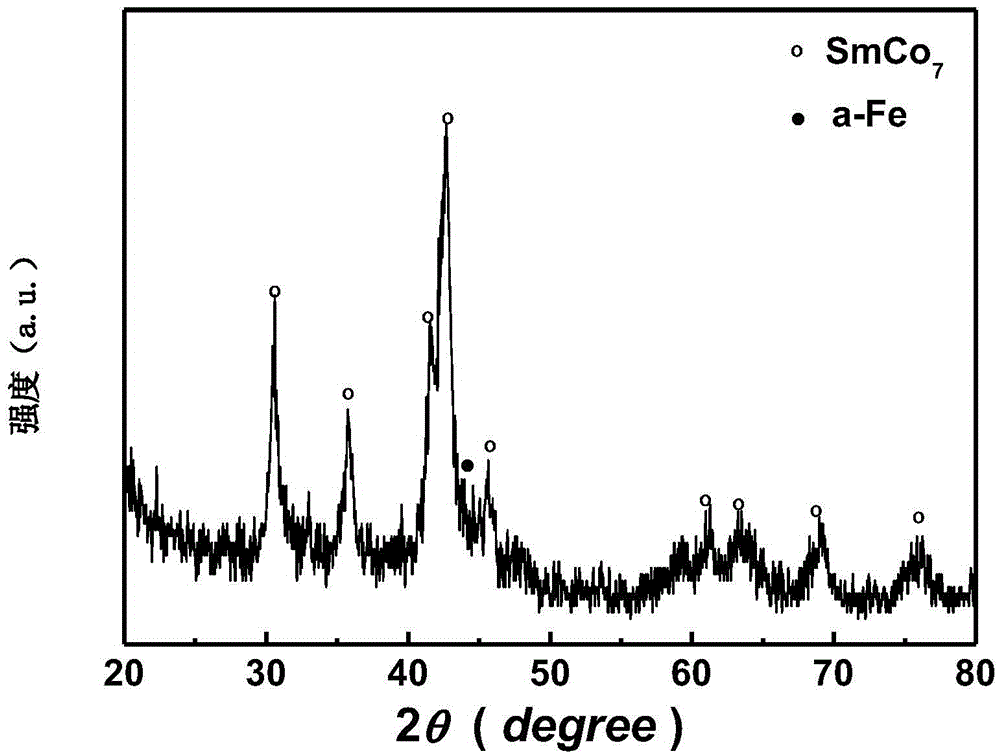

Examples

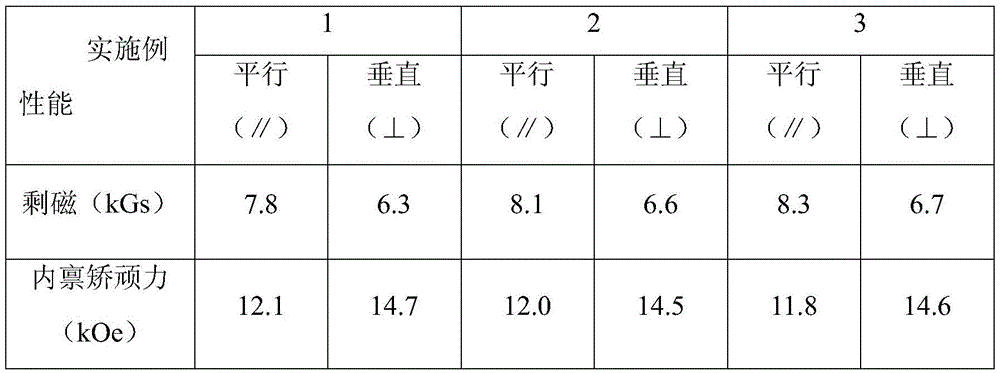

Embodiment 1

[0030] (1) Smelting alloy: first prepare the raw materials, weigh the raw materials according to the following weight ratio: Sm17%, Lu1.5%, Co50.5%, Fe20%, Cu8%, Zr3%, after mixing, put them in a vacuum intermediate frequency induction furnace Melting into alloy ingots at high temperature, vacuumize the furnace body before melting until it reaches 2×10 -4 Pa~6×10 -4 Pa, then filled with high-purity argon to normal pressure and repeated melting at 1330°C for 3 times to ensure the uniformity of the alloy ingot, and then cooled naturally in a medium frequency induction furnace.

[0031] (2) High-energy ball milling: Mechanically crush the samarium-cobalt-based alloy ingot to a coarse powder with a particle size of 1-5 microns, and then add a mixture of 1% oleic acid and n-heptane by the total weight of the composite magnetic powder under the protection of high-purity argon as a ball milling agent (The weight ratio of oleic acid to n-heptane is 1:1). Two agate balls with a diamet...

Embodiment 2

[0035] (1) Alloy smelting: Prepare the raw materials first, and weigh the raw materials according to the following weight ratio: Sm19%, Dy2%, Co55%, Fe18%, Cu5%, Zr1%, after mixing, put them in a vacuum intermediate frequency induction furnace and melt them into alloys at high temperature For ingots, vacuumize the furnace body before smelting until it reaches 2×10 -4 Pa~6×10 -4 Pa, then filled with high-purity argon to normal pressure and repeated melting at 1325°C for 3 times to ensure the uniformity of the alloy ingot, and then cooled naturally in a medium frequency induction furnace.

[0036] (2) High-energy ball milling: Mechanically crush the samarium-cobalt-based alloy ingot to a coarse powder with a particle size of 1-5 microns, and then add a mixture of 1% oleic acid and n-heptane by the total weight of the composite magnetic powder under the protection of high-purity argon as a ball milling agent (The weight ratio of oleic acid to n-heptane is 1:1), steel balls with ...

Embodiment 3

[0039] (1) Smelting alloy: first prepare the raw materials, and take the raw materials according to the following weight ratio: Sm16%,

[0040] Tb1%, Co50.5%, Fe25%, Cu: 5%, Zr: 2.5%, mixed and placed in a vacuum medium frequency induction furnace to be melted into an alloy ingot at a high temperature. Before melting, the furnace body is evacuated until it reaches 2×10 -4 Pa~6×10 -4 Pa, then filled with high-purity argon to normal pressure and repeated melting at 1335°C for 3 times to ensure the uniformity of the alloy ingot, and then cooled naturally in a medium frequency induction furnace.

[0041] (2) High-energy ball milling: mechanically crush samarium-cobalt-based alloy ingots into coarse powder, and then under the protection of high-purity argon, add a mixture of 3% oleic acid and n-heptane by the total weight of the composite magnetic powder as a ball milling agent, with a diameter of 16mm and a diameter of 8mm Two sizes of agate balls are used as grinding bodies, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com