Preparation method of sucrose-free lycium ruthenicum yoghourt wine

A technology of black wolfberry and yogurt wine, applied in the preparation of alcoholic beverages, microorganism-based methods, biochemical equipment and methods, etc., can solve problems such as unfavorable health and immaturity, achieve cardiovascular protection, strong antioxidant capacity, low calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

Specific Example 1

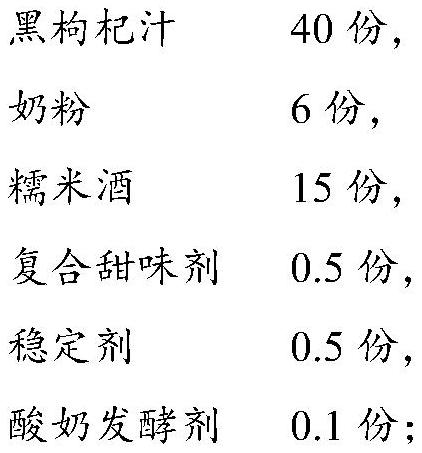

[0042] In the present embodiment, the specific formula by weight is:

[0043]

[0044] Wherein, the yogurt starter includes Streptococcus thermophilus and Lactobacillus thermophilus, and the weight ratio of the two is 1:1; the stabilizer is modified starch; 1 part of sucralose, 50 parts of erythritol, and 0.05 part of coating citric acid.

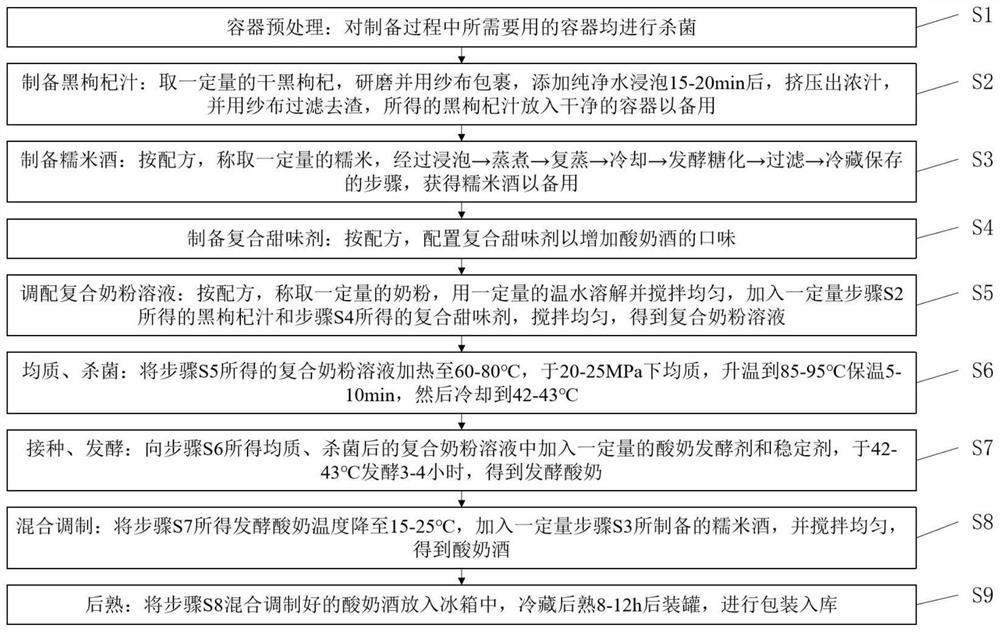

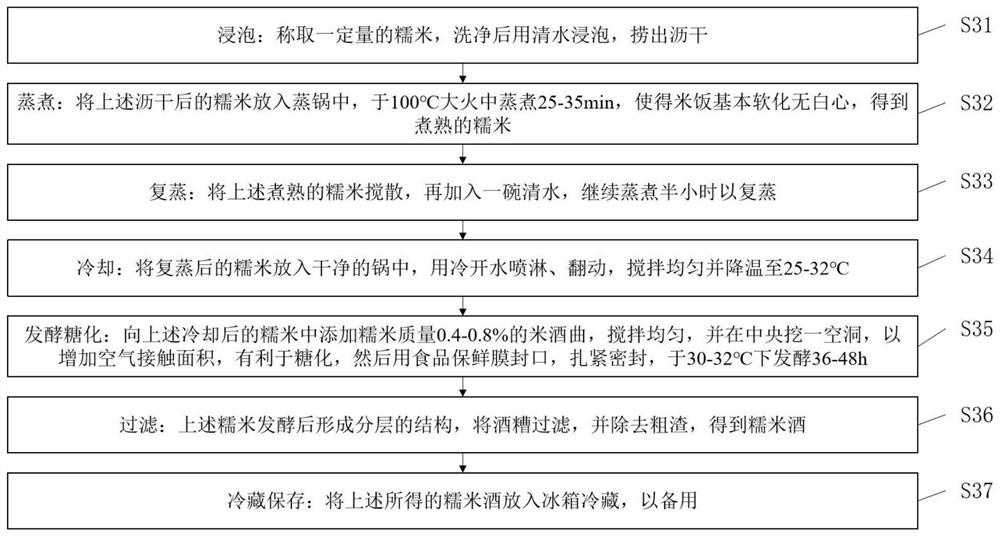

[0045] figure 1 It is a flow chart of a preparation method of a zero sucrose black wolfberry yogurt wine of the present invention, from which it can be seen that the specific preparation method of this implementation is:

[0046] Step S1: Container pretreatment: Sterilize all the containers required in the preparation process.

[0047] Step S2: Preparation of black wolfberry juice: take a certain amount of dried black wolfberry, grind and wrap it with gauze, add purified water and soak for 15 minutes, squeeze out the thick juice, filter with gauze to remove slag, and put the obtained black wolfberry juice into a cl...

specific Embodiment 2

[0055] Step S9: post-cooking: in step S8, the mixed and prepared yogurt wine is placed in the refrigerator, and after being refrigerated and cooked for 8 hours, it is put into a can, and then packaged and put into storage.

Specific embodiment 2

[0057] In the present embodiment, the specific formula by weight is:

[0058]

[0059] Wherein, the yogurt starter includes Streptococcus thermophilus and Lactobacillus thermophilus, and the weight ratio of the two is 3:1; the stabilizer is carrageenan; the compound sweetener is composed of glucosyl stevia by weight 9 parts of glycosides, 3 parts of sucralose, 100 parts of erythritol, and 0.1 part of coating citric acid are mixed.

[0060] figure 1 It is a flow chart of a preparation method of a zero sucrose black wolfberry yogurt wine of the present invention, from which it can be seen that the specific preparation method of this implementation is:

[0061] Step S1: Container pretreatment: Sterilize all the containers required...

specific Embodiment 3

[0069] Step S8: Mixing and modulation: the temperature of the fermented yogurt obtained in step S7 is lowered to 25° C., a certain amount of the glutinous rice wine prepared in step S3 is added, and stirred evenly to obtain yogurt wine.

[0070] Step S9: after-cooking: in step S8, the yogurt wine prepared by mixing and preparing is put into the refrigerator, and after being refrigerated for 12 hours, the yogurt wine is put into a can, and then packaged and put into storage.

Specific embodiment 3

[0072] In the present embodiment, the specific formula by weight is:

[0073]

[0074] Wherein, the yogurt starter includes Streptococcus thermophilus and Lactobacillus thermophilus, and the weight ratio of the two is 2:1; the stabilizer is pectin; 2 parts of sucralose, 80 parts of erythritol, and 0.08 part of coating citric acid.

[0075] figure 1 It is a flow chart of a preparation method of a zero sucrose black wolfberry yogurt wine of the present invention, from which it c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com