Method for extracting and converting saponin in trillium tschonoskii

A technology of trillium and saponins, which is applied in the field of extraction and transformation of saponins in trillium, and can solve the problems of high process cost, cumbersome steps, and long process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

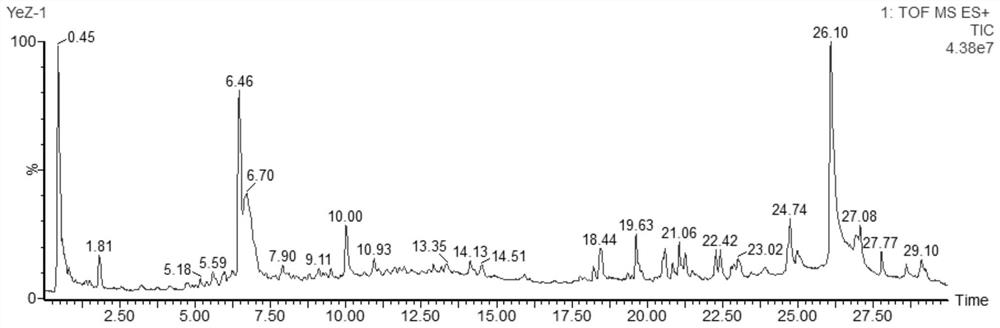

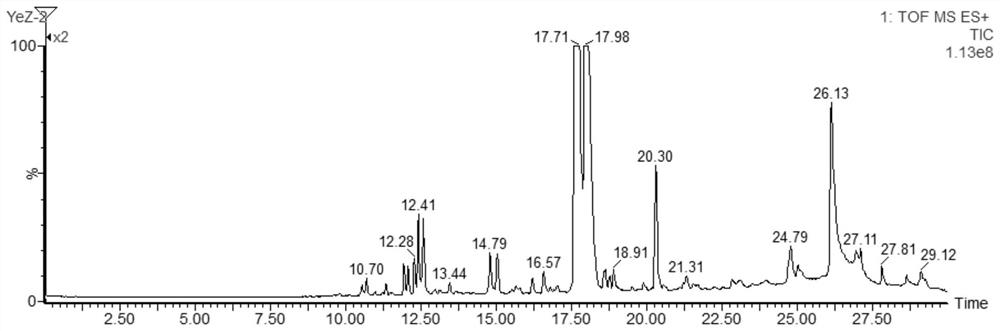

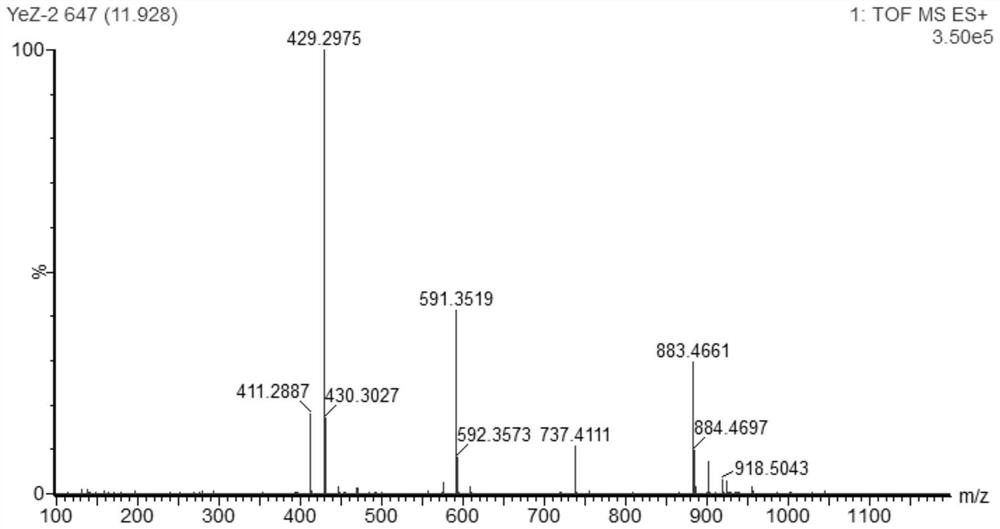

Image

Examples

Embodiment approach 1

[0051] (1) Extraction

[0052] Take 1kg of trillium root and crush it to less than 10 mesh, use 75% ethanol as solvent, the ratio of material to liquid is 1:10, the extraction temperature is 75°C, the extraction time is 3h, and the extraction times are 2 times; the extracts are combined and concentrated in vacuo Ethanol was recovered to obtain 1.5kg of concentrate.

[0053] (2) Enzymatic hydrolysis

[0054] Weigh 30g of rhamnosidase (midsummer) enzyme solution dissolved in 2kg of pure water, add the enzyme solution to the concentrated solution, and keep it at 50°C for enzymatic hydrolysis for 48h, and the solution becomes cloudy.

[0055] (3) cooling crystallization

[0056] The enzymatic hydrolysate was cooled to 5°C and kept for 24 h, and a large amount of precipitation was precipitated; the enzymatic hydrolysate was centrifuged at 3000 g for 15 min while it was cold, and the supernatant was discarded to obtain a precipitate.

[0057] (4) Recrystallization

[0058] The pre...

Embodiment approach 2

[0062] (1) Extraction

[0063] Take 100g of trillium root and crush it to less than 10 mesh, and extract it twice with 70% ethanol. The extraction temperature is 75°C, the extraction time is 2h, and the amount of 70% ethanol is 1L; the extracts are combined, and the ethanol is recovered by vacuum concentration to obtain 200mL. Concentrate.

[0064] (2) Enzymatic hydrolysis

[0065] Weigh 50 g of naringinase (Bohao) enzyme solution dissolved in 500 mL of pure water, add the enzyme solution to the concentrated solution, and keep it at 50 °C for enzymatic hydrolysis for 24 hours, and the solution will continue to become turbid.

[0066] (3) cooling crystallization

[0067] The enzymatic hydrolysate was cooled to 5°C and kept for 24 h, and a large amount of precipitation was precipitated; the enzymatic hydrolysate was centrifuged at 3000 g for 15 min while it was cold, and the supernatant was discarded to obtain a precipitate.

[0068] (4) Recrystallization

[0069] The precip...

Embodiment approach 3

[0073] (1) Extraction

[0074] Take 10kg of trillium root and cut it into thin slices with a slicer, put it into the extraction kettle, and then put 70kg of 60% ethanol as a solvent, set the extraction temperature to 70°C and the extraction time to 3h, and extract twice; The feed liquid is pumped to the concentration kettle through an 800-mesh filter screen, and the ethanol is recovered by vacuum concentration to obtain about 30 kg of concentrated liquid.

[0075] (2) Fermentation

[0076] The strain Lactobacillus rhamnosus was first activated with MRS liquid medium for 2 to 3 generations, and then replaced part of the glucose in the MRS liquid medium with naringin for 3 to 5 generations, and finally the domesticated bacteria were used. fermented extract. The MRS liquid medium was mixed with the concentrated liquid at a ratio of 2:1, and the domesticated strain was inoculated, the fermentation temperature was 35°C, and the fermentation time was 5-7 days.

[0077] (3) Precip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com