Aluminum single atom and ionic liquid loaded oxygen-containing porous carbon material, preparation method and application

A technology of porous carbon materials and ionic liquids, applied in chemical instruments and methods, educts, physical/chemical process catalysts, etc., can solve the problems of difficult catalytic conversion and single active site type, and achieve stable composite structure and good adsorption and activation effect, the effect of excellent thermocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Specifically, as an aspect of the technical solution of the present invention, the related preparation method of an oxygen-containing porous carbon material supporting aluminum single atoms and ionic liquids includes:

[0038] providing a first solution comprising 1-vinyl-3-ethylimidazolium bromide, 1,2-divinylbenzene, azobisisobutylcyanide, and a solvent;

[0039] Hydrothermal reaction of aluminum source and terephthalic acid compound to prepare porous carbon precursor;

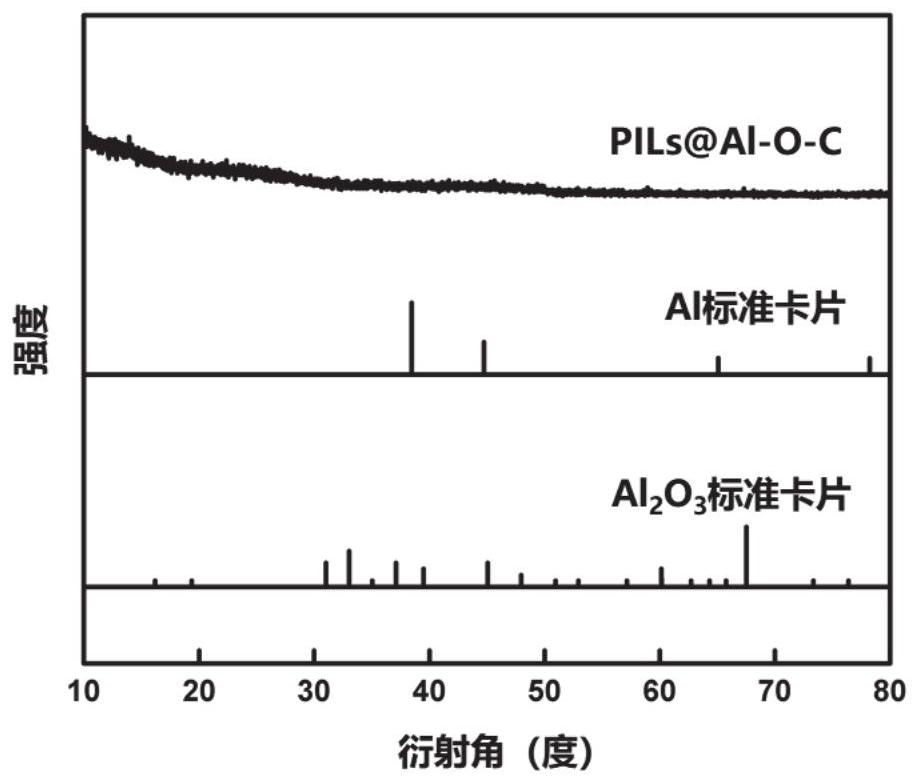

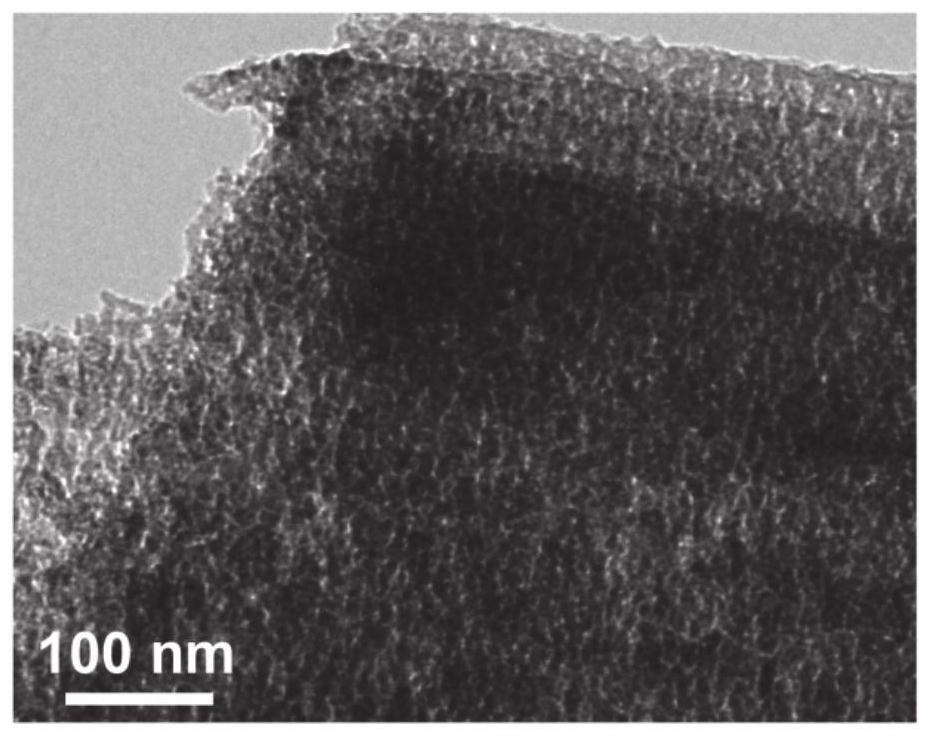

[0040] calcining and etching the porous carbon precursor to obtain an oxygen-containing porous carbon material supporting aluminum single atoms;

[0041] And, heating and reacting the oxygen-containing porous carbon material containing the single-aluminum atom-supported oxygen-containing carbon material with the first solution to prepare the oxygen-containing porous carbon material supporting single-aluminum atoms and the ionic liquid.

[0042] In some preferred embodiments, the preparation method sp...

Embodiment 1

[0089] Synthesis of Oxygen-Containing Porous Carbon Materials Supporting Aluminum Single Atoms:

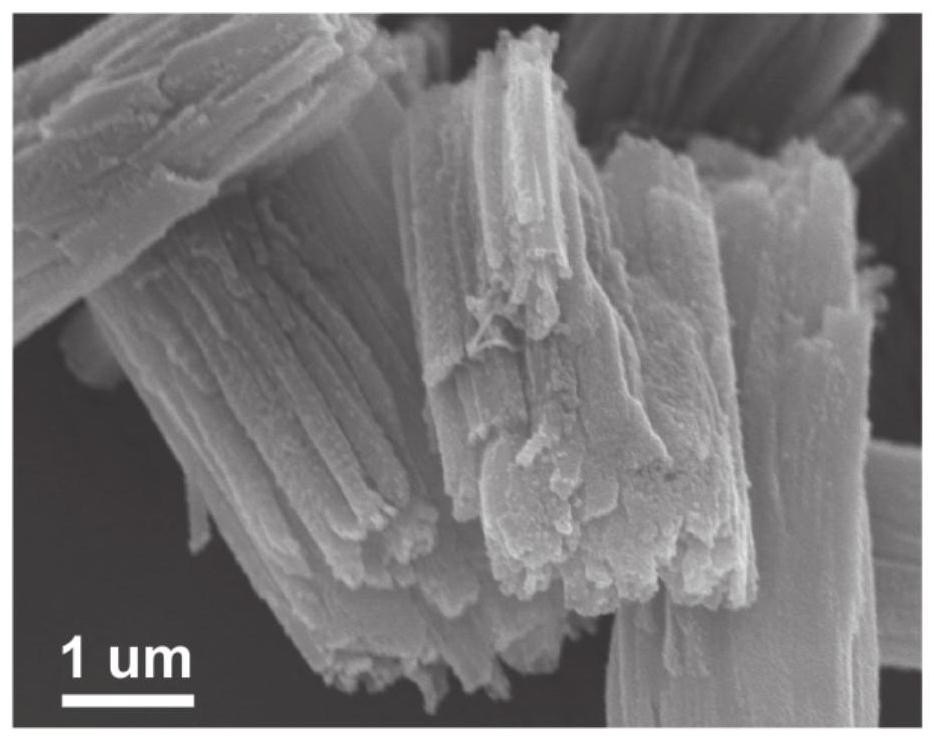

[0090]The aluminum nitrate nonahydrate of 35mmol and the terephthalic acid of 17mmol were added to 2.78mol deionized water, then the high-pressure hydrothermal reactor of 100mL capacity was charged, and reacted for 3 days at 220°C, then naturally cooled to room temperature, then Wash once with ethanol to obtain a white precipitate, then put all the white precipitate in a 500mL round-bottomed flask, add 250mL of absolute ethanol, reflux in an oil bath at 80°C for 12h, repeat the reflux twice, the main purpose of this step of reflux treatment is to Unreacted terephthalic acid was removed as much as possible to avoid affecting the subsequent synthesis. After refluxing, washing with ethanol and centrifuging twice, and then vacuum drying at 60°C overnight, the porous carbon precursor was obtained. Then calcined, took an appropriate amount of precursor and placed it in a porcelain boat...

Embodiment 2

[0092] First, 0.48 mmol of 1-vinyl-3-ethylimidazolium bromide, 0.4 mmol of 1,2-divinylbenzene and 0.016 mmol of azobisisobutyl cyanide were placed in a round bottom flask with 7.2 mmol of Absolute ethanol was dissolved, then 100 mg of Al-O-C in Example 1 was added, then an Ar balloon was connected, and the air in the flask was removed by a circulating water vacuum pump, and the flask was sonicated until the solution was completely infiltrated with Al-O-C. Pump vacuum again until no air bubbles emerge from the mixture. The above-mentioned ultrasonic and pumping steps are the key steps in the synthesis, and the purpose is to enable the reactant solution to enter the Al-O-C pores, and then to polymerize in the pores to form a composite structure during heating and reaction. Finally, the flask was placed in an oil bath at 70°C for 24 hours, during which time the water was pumped three times with a circulating water vacuum pump. After the reaction, it was washed with ethanol for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com