A method for measuring transverse relaxation rate of wood cell wall pore surface

A technology of transverse relaxation rate and measurement method, which is applied in the field of determination of transverse relaxation rate of wood cell wall pore surface, can solve the problems of long test time, large deviation of measurement results, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] The method for determining the transverse relaxation rate of the pore surface of the wood cell wall described in this embodiment includes the following steps:

[0078] (1) Select the wood sample for thermogravimetric analysis, and determine the heat treatment temperature to be 200 °C to prevent the heat treatment temperature from being too high to damage the chemical components of the cell wall of the wood sample and affect the determination of cell wall pores;

[0079] (2) Heat-treating the wood sample, drying the wood sample at 105°C until it is absolutely dry, and recording the mass m a =0.885g, then under nitrogen protection, the temperature was increased to 200°C at a programmed rate of 5°C / min, and then kept for 5 hours to obtain a heat-treated sample. The mass of the heat-treated sample was m b =0.878g, mass loss rate (m a -m b )×100% / m a = 0.791%, controlled within the range of 0-1%, to prevent heat treatment from damaging the chemical components of the cell ...

Embodiment 2

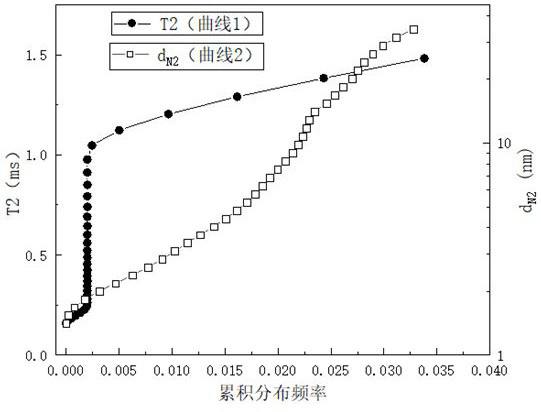

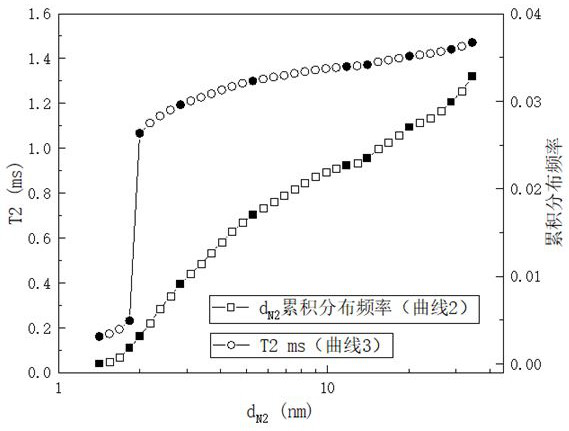

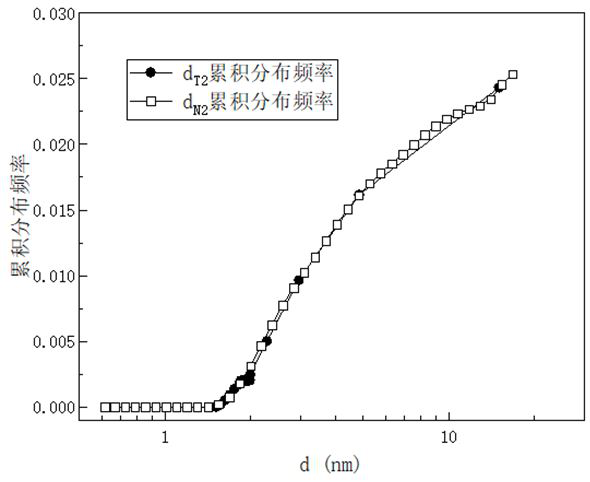

[0122] The method for measuring the transverse relaxation rate of the pore surface of the wood cell wall described in this example is the same as the method in Example 1, except that in step (11), the starting point and the ending point of the part with the same slope in the curve 2 are selected as the curve 2 The data between each node comes from the same type of pore system; by comparing curve 2 and curve 3, the distribution nodes of curve 2 correspond to the same d on curve 3 N2 The data points are used as the distribution nodes of curve 3;

[0123] The distribution nodes of curve 2 in this embodiment are: figure 2 In the middle curve 2, the remaining nodes except the second and third distribution nodes (arranged in the order of nitrogen adsorption pore size from small to large) are not shown in additional drawings in order to save space. Through weighted linear regression, the values of Q and K corresponding to the nitrogen adsorption pore size and nuclear magnetic por...

Embodiment 3

[0127] The method for measuring the transverse relaxation rate of the pore surface of the wood cell wall described in this example is the same as the method in Example 1, except that in step (11), the starting point and the ending point of the part with the same slope in the curve 3 are selected as the distribution of the curve 3 nodes, the data between each node comes from the same type of pore system; the distribution nodes of curve 3 in this embodiment do not include figure 2 The 7th, 8th, and 9th distribution nodes of curve 3 in the middle (arranged in ascending order of nitrogen adsorption aperture), other distribution nodes are the same as those in Example 1. To save space, no additional drawings are added.

[0128] Through weighted linear regression, the values of Q and K corresponding to the nitrogen adsorption pore size and nuclear magnetic pore size between each distribution node are determined, and the surface transverse relaxation rate ρ of the cell wall pores of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com