Method and device for purifying tetrafluoroethylene polymerization reaction kettle recovery gas

A polymerization reactor, tetrafluoroethylene technology, applied in chemical instruments and methods, separation methods, halogenated hydrocarbon disproportionation separation/purification, etc., can solve the problems affecting the normal production of the device, product quality, equipment, pipeline and instrument blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment provides a method for purifying recovered gas from a tetrafluoroethylene polymerization reactor.

[0048] The temperature of the recovered gas from the treated tetrafluoroethylene polymerization reactor is about 40-50° C., and it contains about 2-5% (w / w) of gas-phase paraffin. The actual measured value of the content of gas-phase paraffin fluctuates, and the average value is about 4%.

[0049] The recovered gas from the polymerization reactor is continuously fed into the spray tower, flows upward in the spray tower, and is in countercurrent contact with the spray liquid sprayed from the upper part of the spray tower, and the spray liquid is calcium chloride brine. The top pressure of the spray tower is 0.05~0.1MPa; the temperature of the lower part of the tower, that is, the lower part of the tower body, is -10~-15℃; the temperature of the tower still is 45~50℃. The spray density of the spray liquid is 8-12m 3 / m 2 〃h. The lower part of the tower bo...

Embodiment 2

[0057] In this example, the liquid-phase paraffin obtained in Example 1 was treated. Specifically, paraffin wax liquid is granulated in water to make paraffin wax solid particles.

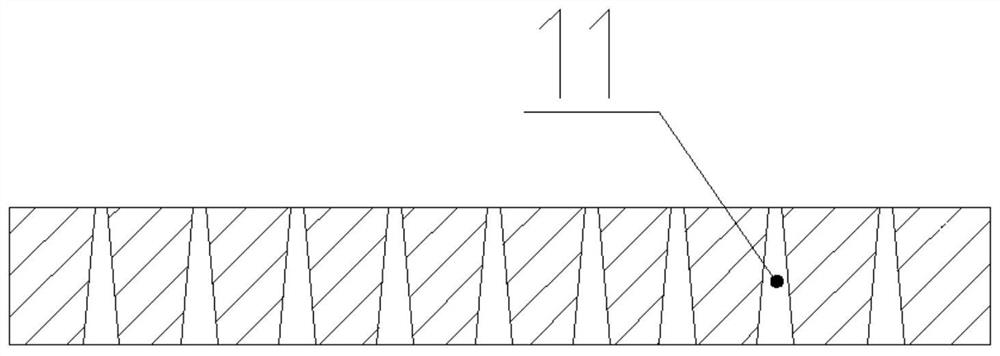

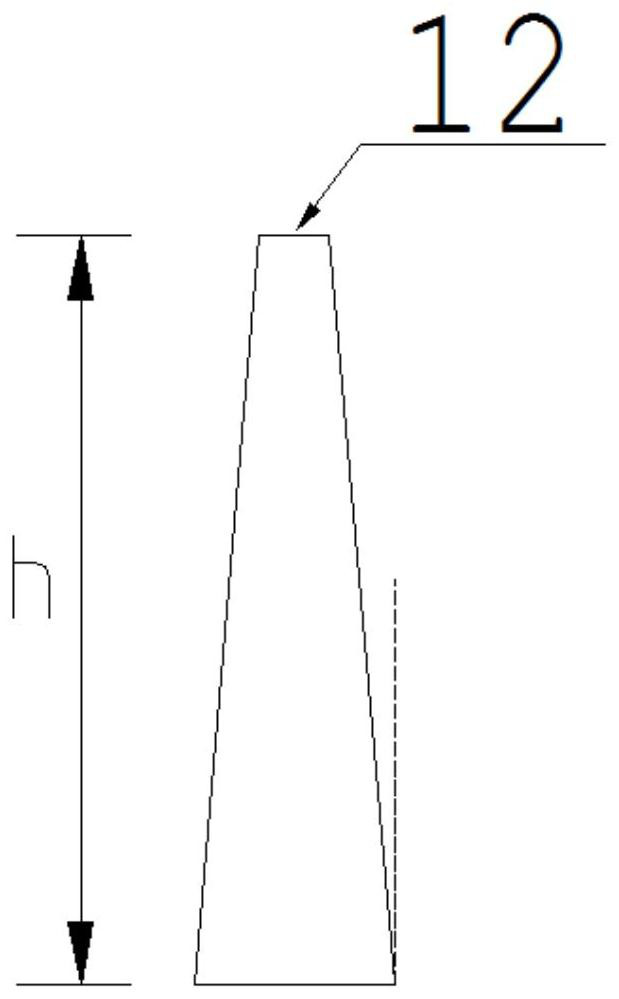

[0058] The granulation process is carried out in a granulation tank, which is filled with water. See Figure 1-3 As shown, the inner cavity of the granulation tank 6 is provided with an extruder 7, which divides the inner cavity of the granulation tank 6 into an upper chamber arranged up and down and a lower chamber for filling paraffin liquid , the chamber wall of the upper chamber is provided with a paraffin particle outlet 10, the lower chamber is communicated with the paraffin liquid outlet of the spray tower through the paraffin conveying pipeline 5, and the extruder 7 has the function of connecting the upper chamber and the lower chamber. In the process of paraffin floating from bottom to top, the paraffin wax particles are extruded to form holes 11 .

[0059] The paraffin particle forming...

Embodiment 3

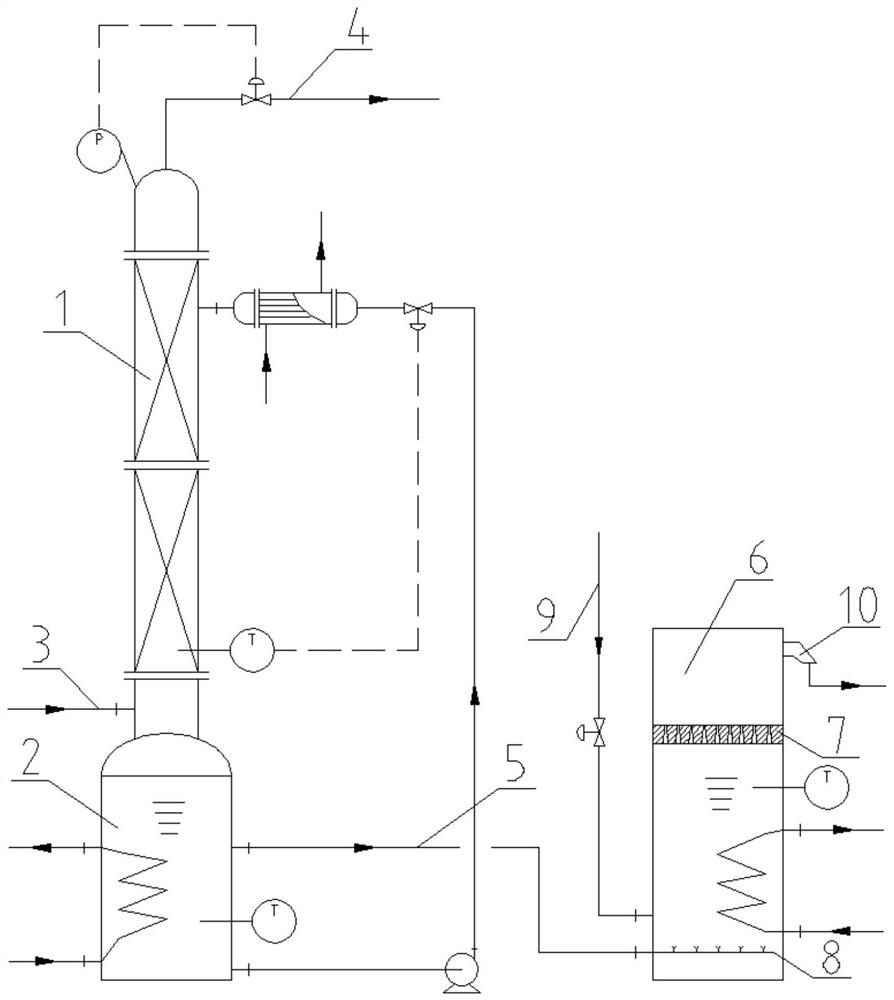

[0071] This embodiment provides a purification device for the recovered gas from a tetrafluoroethylene polymerization reactor, see Figure 1-Figure 3 As shown, the purification device includes a spray tower system for purification and a granulation system for granulating liquid paraffin.

[0072] As shown, the device includes a granulation tank 6 and a spray tower 1 with an outlet for paraffin liquid.

[0073] The lower part of the spray tower 1 is the spray tower tower kettle 2. The spray tower tower body is provided with a tetrafluoroethylene polymerization reactor recovery gas inlet 3 near the tower kettle, and the spray tower tower top is the purification recovery gas outlet 4. The spray tower The tower kettle 2 is provided with a middle overflow port, that is, a paraffin liquid outlet, and the middle overflow port is connected with the paraffin transportation pipeline 5, and the upper layer liquid paraffin in the tower kettle enters the granulation tank 6 through the para...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com