Mordenite and preparation method thereof

A technology of mordenite and crystal grains, which is applied in the field of mordenite and its preparation, and can solve the problems of large influence of mordenite framework structure, increased production cost, environmental pollution and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

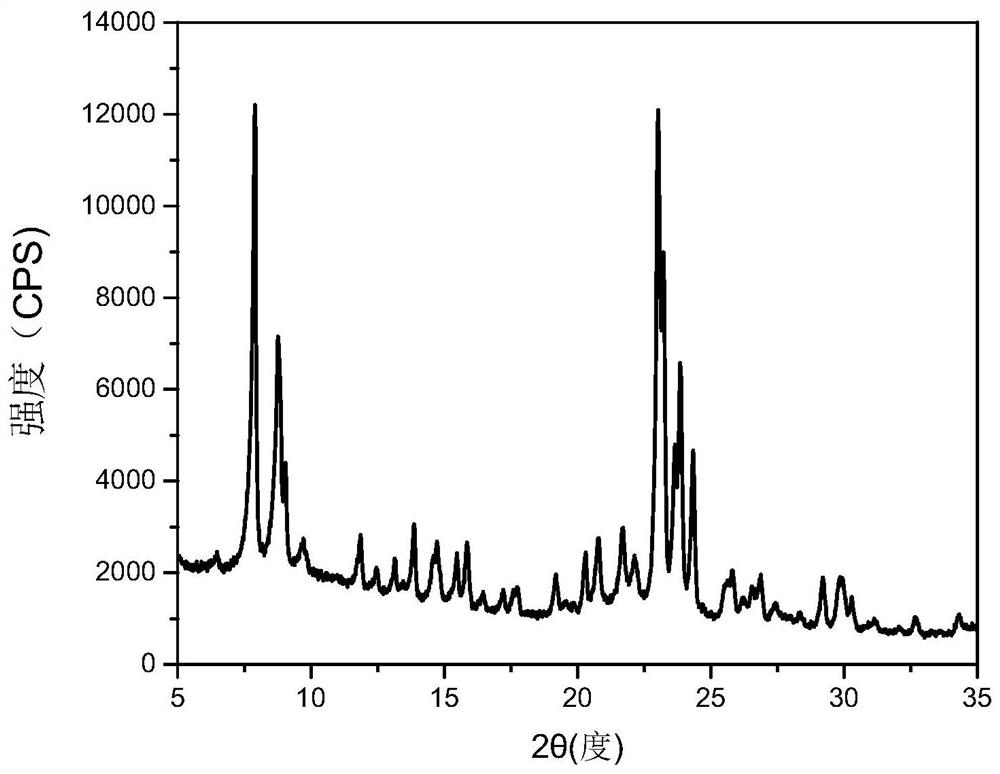

Image

Examples

Embodiment 1

[0037] According to the molar composition of the reaction mixture: Si0 2 / A1 2 0 3 =60, H 2 0 / Si0 2 =5, R / Si0 2 =0.08, Na 2 0 / Si0 2 =0.10, followed by sodium metaaluminate solution, deionized water, 1,1,4,4-tetraethyl-1,4-diazonane-1,4-diammonium base (structure directing agent R), hydrogen Add sodium oxide and coarse silica gel to a 45mL Teflon container, stir well with a glass rod, mix the solid and liquid thoroughly for 15 minutes, cover the Teflon container, and put it into a steel high pressure The kettle was sealed to prevent leakage of the mixture in the container.

[0038] The above-mentioned autoclave filled with the mixture was placed in a rotating convection oven at 120° C., the rotation speed was set to 20 rpm, and the reaction was carried out for 1 day. The temperature was raised to 160° C. and the reaction was carried out for 6 days. After the reaction, the autoclave continued to stay in the oven for one day, cooled to room temperature naturally, and then...

Embodiment 2

[0044] According to the molar composition of the reaction mixture: Si0 2 / A1 2 0 3 =90, H 2 0 / Si0 2 =6.5, R / Si0 2 =0.15, Na 2 0 / Si0 2 =0.10, followed by sodium metaaluminate solution, deionized water, 1,1,4,4-tetraethyl-1,4-diazonane-1,4-diammonium base (structure directing agent R), hydrogen Add sodium oxide and coarse silica gel to a 45mL Teflon container, stir well with a glass rod, mix the solid and liquid thoroughly for 15 minutes, cover the Teflon container, and put it into a steel high pressure The kettle was sealed to prevent leakage of the mixture in the container.

[0045] The above-mentioned autoclave filled with the mixture was placed in a rotating convection oven at 120° C., the rotation speed was set to 20 rpm, and the reaction was carried out for 1 day. The temperature was raised to 160° C. and the reaction was carried out for 6 days. After the reaction, the autoclave continued to stay in the oven for one day, cooled to room temperature naturally, and th...

Embodiment 3

[0051] According to the molar composition of the reaction mixture: Si0 2 / A1 2 0 3 =120, H 2 0 / Si0 2 =6.5, R / Si0 2 =0.08, Na 2 0 / Si0 2 =0.10, followed by sodium metaaluminate solution, deionized water, 1,1,4,4-tetraethyl-1,4-diazonane-1,4-diammonium base (structure directing agent R), hydrogen Add sodium oxide and coarse silica gel to a 45mL Teflon container, stir well with a glass rod, mix the solid and liquid thoroughly for 15 minutes, cover the Teflon container, and put it into a steel high pressure The kettle was sealed to prevent leakage of the mixture in the container.

[0052] The above-mentioned autoclave filled with the mixture was placed in a rotating convection oven at 120° C., the rotation speed was set to 20 rpm, and the reaction was carried out for 1 day. The temperature was raised to 160° C. and the reaction was carried out for 6 days. After the reaction, the autoclave continued to stay in the oven for one day, cooled to room temperature naturally, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com