High-temperature-resistant high-filtration composite fiber membrane and preparation method thereof

A composite fiber membrane, high temperature resistant technology, applied in the direction of separation method, filtration separation, membrane filter, etc., to achieve the effect of improving electrostatic filtration performance, long service life, and convenient large-scale application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A preparation method of a high temperature resistant and high filtration composite fiber membrane provided by the invention comprises the following steps:

[0028] S1. respectively prepare a polyamic acid spinning solution and a polyacrylonitrile spinning solution, and the polyamic acid spinning solution is added with tourmaline; by adding tourmaline to the polyamic acid spinning solution, on the one hand, using The self-generating polarity of tourmaline improves the subsequent charge storage performance; on the other hand, the high dielectric constant of tourmaline is used to increase the dielectric constant difference between polyimide fibers and polyacrylonitrile fibers to improve triboelectric charging. performance.

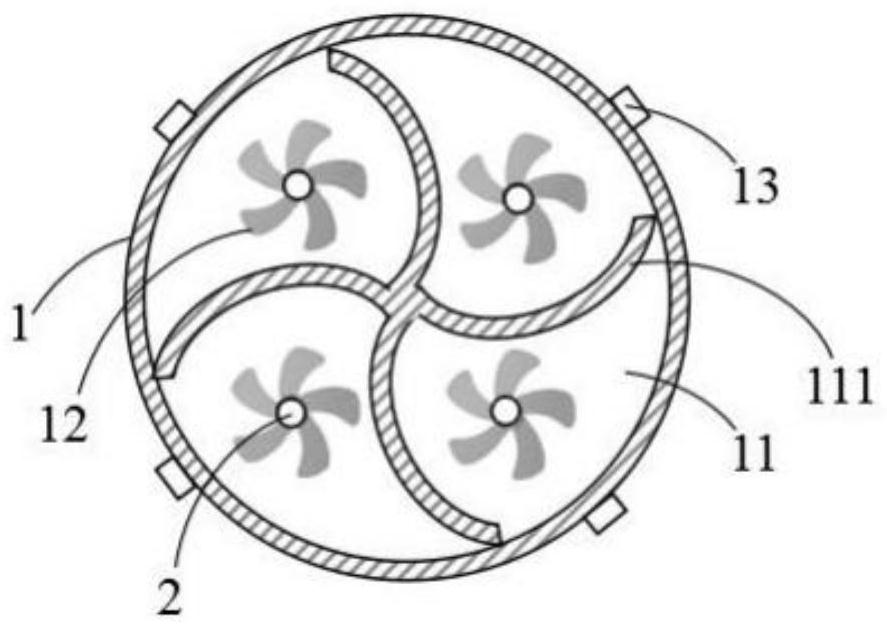

[0029] S2. The polyamic acid spinning solution and the polyacrylonitrile spinning solution are synchronously or alternately centrifuged and deposited to obtain a composite fiber membrane; the rotational speed of the centrifugal spinning is 2000-5000 rp...

Embodiment 1

[0044] A preparation method of a high temperature resistant and high filtration composite fiber membrane, comprising the following steps:

[0045] S1. the preparation of spinning solution: adding tourmaline powder and antibacterial agent to the polyamic acid solution, mixing uniformly to obtain polyamic acid spinning solution (wherein, the contents of tourmaline powder, antibacterial agent and polyamic acid are respectively 5wt%, 3wt% %, 20wt%), adding polyacrylonitrile to N,N-dimethylformamide, and mixing evenly to obtain 22wt% polyacrylonitrile spinning solution;

[0046] S2. Preparation of polyamic acid / polyacrylonitrile composite fiber membrane: Pour the polyamic acid spinning solution and polyacrylonitrile spinning solution prepared in step S1 into a spinner with at least two holding chambers for synchronous centrifugal spinning silk to obtain a composite fiber membrane, wherein the average fiber diameter is 0.4-5 μm;

[0047] S3. Imidization of the polyamic acid / polyacr...

Embodiment 2-5

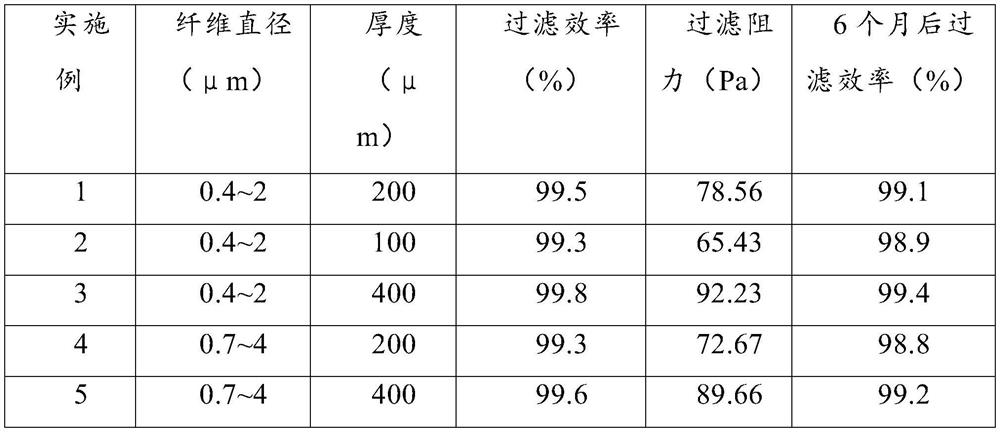

[0049] A preparation method of a high temperature resistant and high filtration composite fiber membrane, compared with Example 1, the difference is that the average fiber diameter and the thickness of the composite fiber membrane are shown in Table 1, and the others are roughly the same as Example 1, here No longer.

[0050] The test results of table 1 embodiment 1-5

[0051]

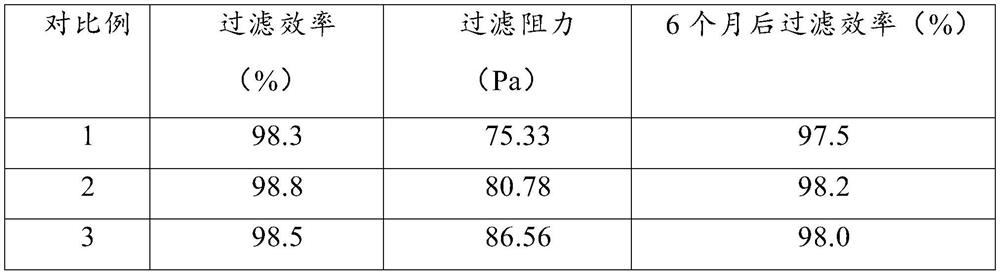

[0052] As can be seen from Table 1, the present invention can achieve a filtration efficiency of 99.5% without electret treatment, and the filtration resistance is lower than 80Pa. After being placed for 6 months, the filtration efficiency can still reach 99.1%, indicating the service life of electrostatic filtration. It can achieve long-term and high-efficiency filtration performance through self-friction electrification, which is of great significance for filtration in high temperature environments. When the thickness of the fiber membrane is the same, the smaller the fiber diameter, the higher t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com