Degradable thermosetting 3D printing mold and preparation method thereof

A 3D printing and thermosetting technology, applied in 3D object support structures, manufacturing tools, additive manufacturing, etc., can solve the problems of low precision and dimensional stability, and achieve good dimensional stability, high printing precision, and good process controllability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

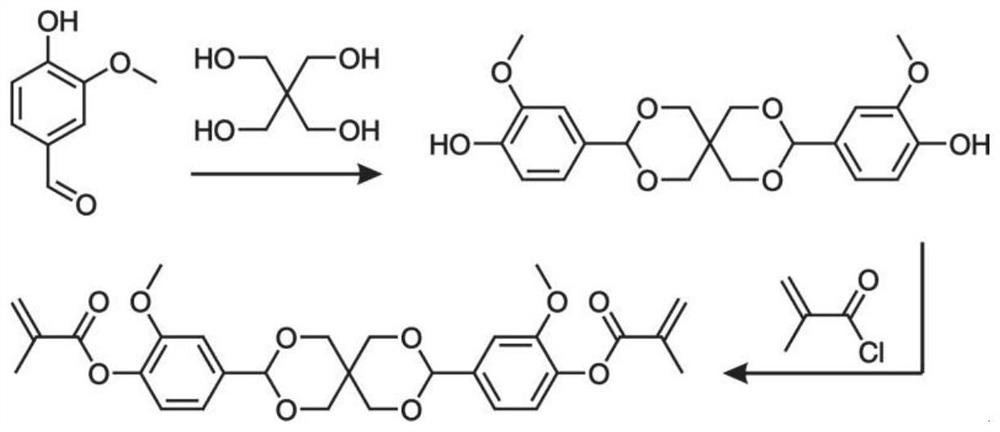

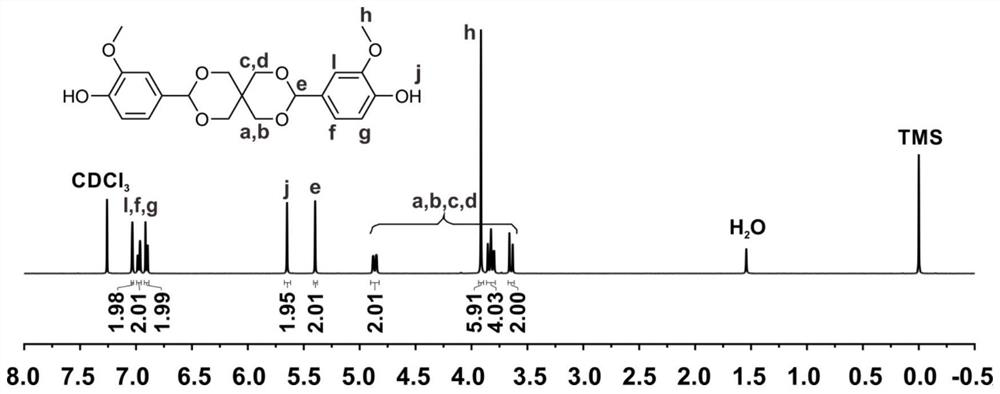

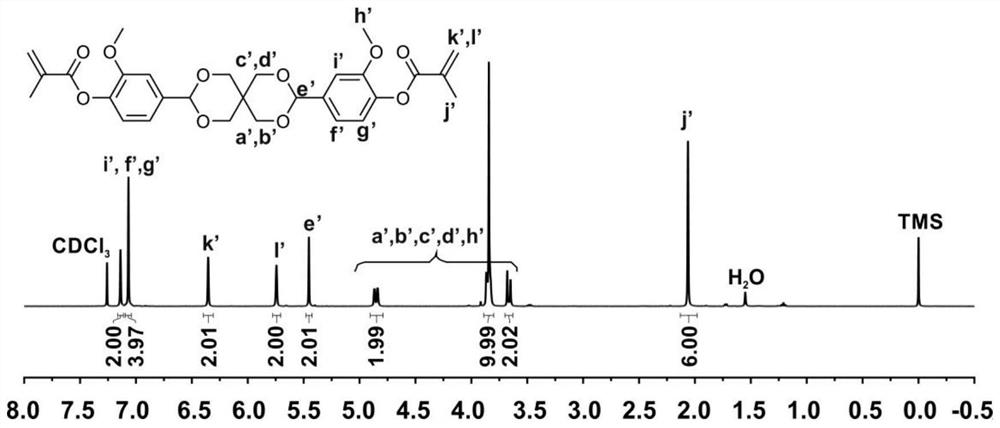

[0040] 1) (2,4,8,10-Tetraoxaspiro[5.5]undecane-3,9-diyl)bis(2-methoxy-4,1-phenylene)bis(acrylic acid 2- Preparation of methyl ester)

[0041]A solution of vanillin (60.86 g, 400 mmol), pentaerythritol (22.23 g, 200 mmol) and p-toluenesulfonic acid monohydrate (836.5 mg, 4.4 mmol) in 2-propanol (500 mL) was reacted at room temperature for 24 h. The solid product was obtained by filtration, and 300 ml of 2wt% NaHCO was used in turn 3 The solution was washed with 100 ml of deionized water. The crude product was refluxed in isopropanol (150 mL) for 30 minutes and cooled to room temperature. 4,4'-(2,4,8,10-tetraoxaspiro[5.5]undecan-3,9-diyl)bis(2-methoxyphenol) was obtained by filtration as a white solid. 4,4'-(2,4,8,10-Tetraoxaspiro[5.5]undecan-3,9-diyl)bis(2-methoxyphenol) (40.44 g, 100 mmol) was added with stirring ) and triethylamine (24.28 g, 240 mmol) were dissolved in dichloromethane (400 mL). A solution of methacryloyl chloride (20.91 g, 200 mmol) in dichloromethane (2...

Embodiment 2

[0055] 1) (2,4,8,10-Tetraoxaspiro[5.5]undecane-3,9-diyl)bis(2-methoxy-4,1-phenylene)bis(acrylic acid 2- Preparation of methyl ester)

[0056] A solution of vanillin (60.86 g, 400 mmol), pentaerythritol (17.78 g, 160 mmol) and p-toluenesulfonic acid monohydrate (380.23 mg, 2.0 mmol) in 2-propanol (500 mL) was reacted at 30° C. for 12 h. The solid product was obtained by filtration, and 300 ml of 2wt% NaHCO was used in turn 3 The solution was washed with 100 ml of deionized water. The crude product was refluxed in isopropanol (150 mL) for 30 minutes and cooled to room temperature. 4,4'-(2,4,8,10-tetraoxaspiro[5.5]undecan-3,9-diyl)bis(2-methoxyphenol) was obtained by filtration as a white solid. 4,4'-(2,4,8,10-Tetraoxaspiro[5.5]undecan-3,9-diyl)bis(2-methoxyphenol) (40.44 g, 100 mmol) was added with stirring ) and triethylamine (24.28 g, 240 mmol) were dissolved in dichloromethane (400 mL). A solution of methacryloyl chloride (19.87 g, 190 mmol) in dichloromethane (200 mL) w...

Embodiment 3

[0060] 1) (2,4,8,10-Tetraoxaspiro[5.5]undecane-3,9-diyl)bis(2-methoxy-4,1-phenylene)bis(acrylic acid 2- Preparation of methyl ester)

[0061] A solution of vanillin (60.86 g, 400 mmol), pentaerythritol (26.67 g, 240 mmol) and p-toluenesulfonic acid monohydrate (3802.3 mg, 20 mmol) in 2-propanol (500 mL) was reacted at 10 °C for 48 h. The solid product was obtained by filtration, and 300 ml of 2wt% NaHCO was used in turn 3The solution was washed with 100 ml of deionized water. The crude product was refluxed in isopropanol (150 mL) for 30 minutes and cooled to room temperature. 4,4'-(2,4,8,10-tetraoxaspiro[5.5]undecan-3,9-diyl)bis(2-methoxyphenol) was obtained by filtration as a white solid. 4,4'-(2,4,8,10-Tetraoxaspiro[5.5]undecan-3,9-diyl)bis(2-methoxyphenol) (40.44 g, 100 mmol) was added with stirring ) and triethylamine (24.28 g, 240 mmol) were dissolved in dichloromethane (400 mL). A solution of methacryloyl chloride (21.96 g, 210 mmol) in dichloromethane (200 mL) was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com