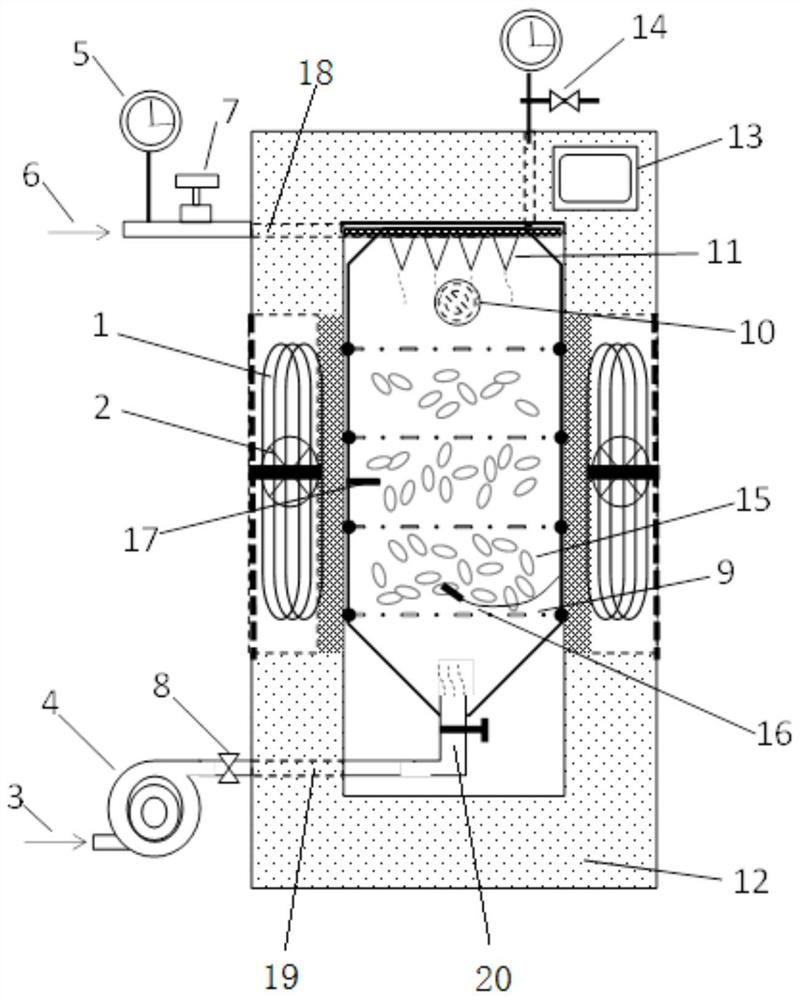

Static magnetic field assisted liquefied CO2 pulse spouting quick freezing device and pressurized efficient freezing method

A technology of pulse jetting and quick-freezing device, which is used in food freezing, household refrigeration devices, cooling fluid circulation devices, etc. It is difficult to obtain guarantees and other problems to achieve the effects of rapid freezing and uniform internal and external, uniform freezing and magnetic field assistance, and maintenance of physical and chemical and nutritional indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

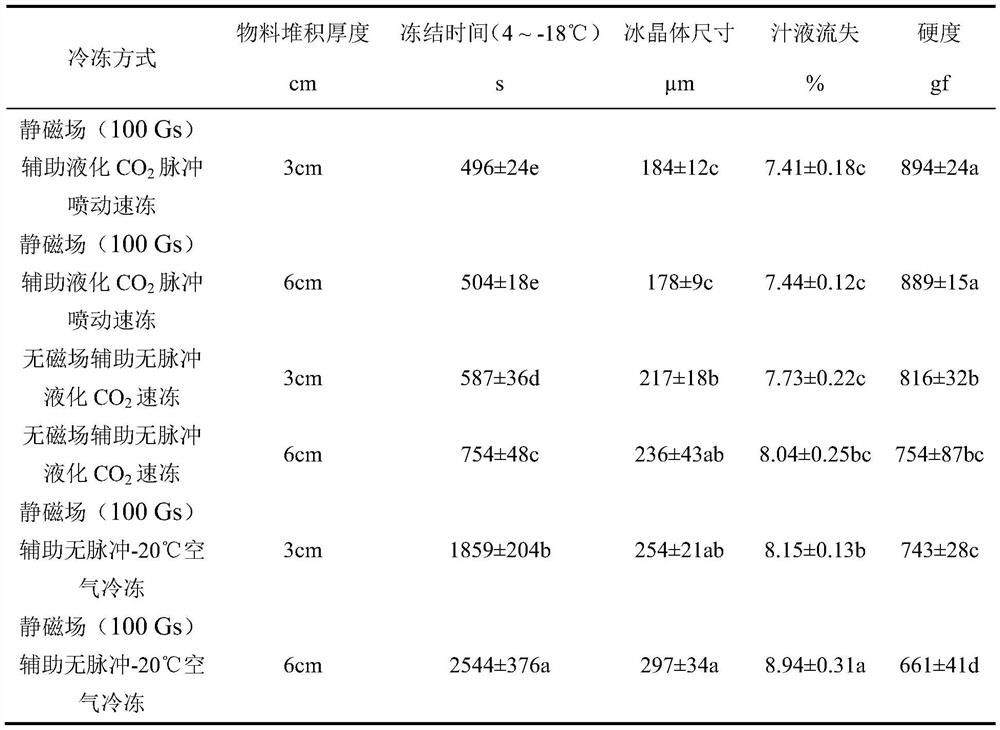

Embodiment 1

[0068] Example 1: Cantaloupe

[0069] (1) Raw material pretreatment

[0070] a. Raw material screening and cleaning: select cantaloupe melons with uniform size, moderate maturity, and no mechanical damage, and then clean them;

[0071] b. Slicing: Slice the cleaned cantaloupe along the central equator, and then use a self-made punch to punch out a cylindrical cantaloupe sample with a diameter of 2.5 cm and a height of 3 cm.

[0072] (2) Raw material pre-cooling and CO 2 pre-pressurized

[0073] Put the cantaloupe block into the grid sample tray, then put it in the freezer, insert the precision thermocouple into the center of the cantaloupe block sample of different layers, measure the temperature change of the center, close the airtight hatch and the exhaust port. Turn on the vacuum pump to draw out the air in the freezer and turn off the vacuum pump. Open the flow regulating valve, adjust the flow to low speed, and input liquefied CO 2 to the freezer until the temperatur...

Embodiment 2

[0085] Example 2: Summer Black Grapes

[0086] (1) Raw material pretreatment

[0087] Select the fruits of summer black grapes with uniform size, moderate maturity, and no mechanical damage, pick the fruit, clean it, and drain the water.

[0088] (2) Raw material pre-cooling and CO 2 pre-pressurized

[0089] Put the grape fruit into the tray, and then put it in the freezing device, and insert the precision thermocouple in the device into the center of the grape samples in different layers, measure the temperature change of the center, and close the sealed hatch and exhaust port. Turn on the vacuum pump to draw out the air in the freezer and turn off the vacuum pump. Turn on liquefied CO 2 valve, adjust the flow valve to low speed, input liquefied CO 2 to a freezer temperature of 4°C. At the same time, the internal pressure was adjusted to 1MPa, and the pressurized state was maintained for 20min.

[0090] (3) Static magnetic field assisted liquefaction of CO 2 Pulse jet...

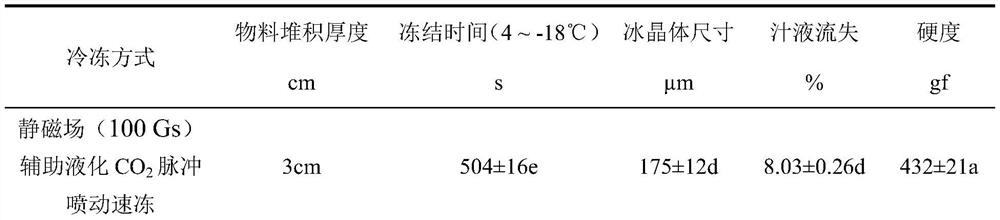

Embodiment 3

[0102] Example 3: Carrots

[0103] (1) Raw material pretreatment

[0104] a. Raw material screening and cleaning: select carrots with uniform size, moderate maturity and no mechanical damage, and then clean them;

[0105] b. Slicing: Use a self-made punch to punch out a cylinder with a diameter of 2.5 cm from the cleaned carrots, and then cut into samples with a thickness of 1 cm.

[0106] (3) Raw material pre-cooling and CO 2 pre-pressurized

[0107] Put the carrot slices into the tray, and then put them in the freezing device, insert the precision thermocouple in the device into the center of the carrot samples in different layers, measure the temperature change of the center, and close the airtight hatch and exhaust port. Turn on the vacuum pump to draw out the air in the freezer and turn off the vacuum pump. Turn on liquefied CO 2 valve, adjust the flow valve to low speed, input liquefied CO 2 to a freezer temperature of 4°C. At the same time, the internal pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com