Semiconductor wafer thinning device with dust treatment function

A technology for dust treatment and semiconductors, which is applied in semiconductor/solid-state device manufacturing, gas treatment, and the use of liquid separation agents, etc. It can solve the problems of easy damage to wafers, easy entry of dust into other equipment, environmental pollution, etc., and speed up the thinning rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

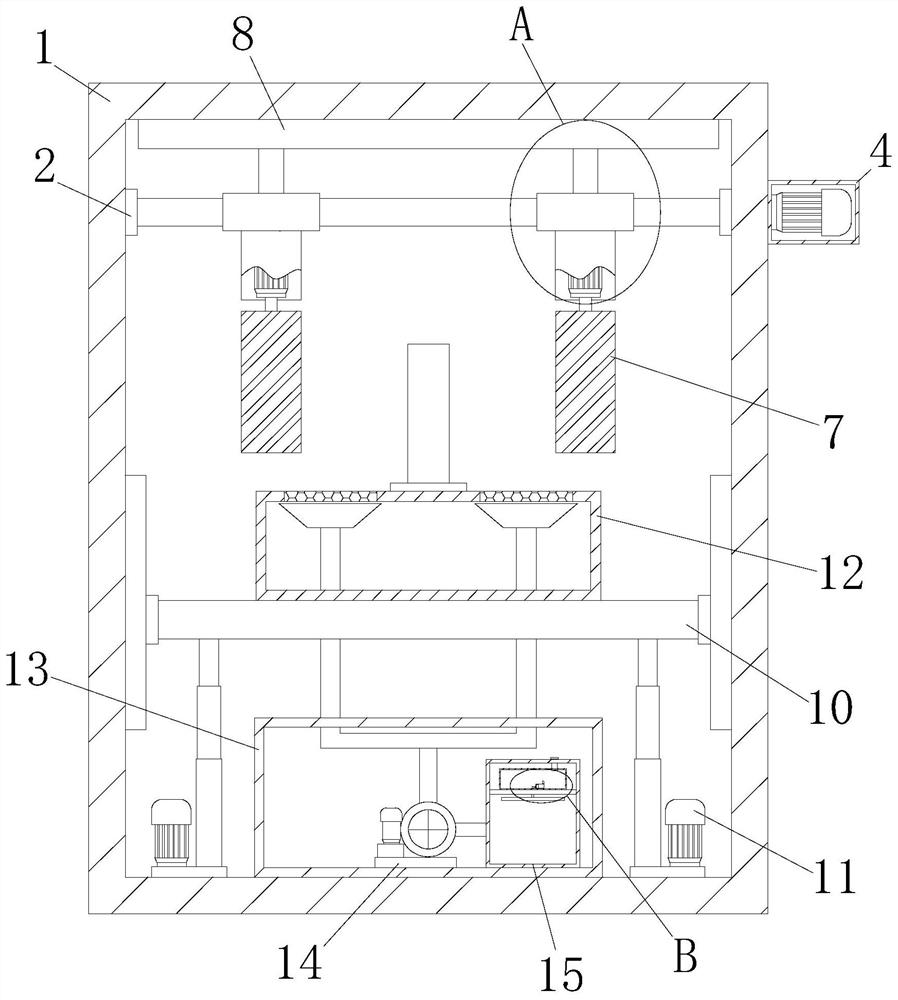

[0023] according to Figure 1-4 , a semiconductor wafer thinning device with a dust processing function, comprising a thinning box 1 , a thinning mechanism and a collecting mechanism, both of which are fixedly installed in the thinning box 1 .

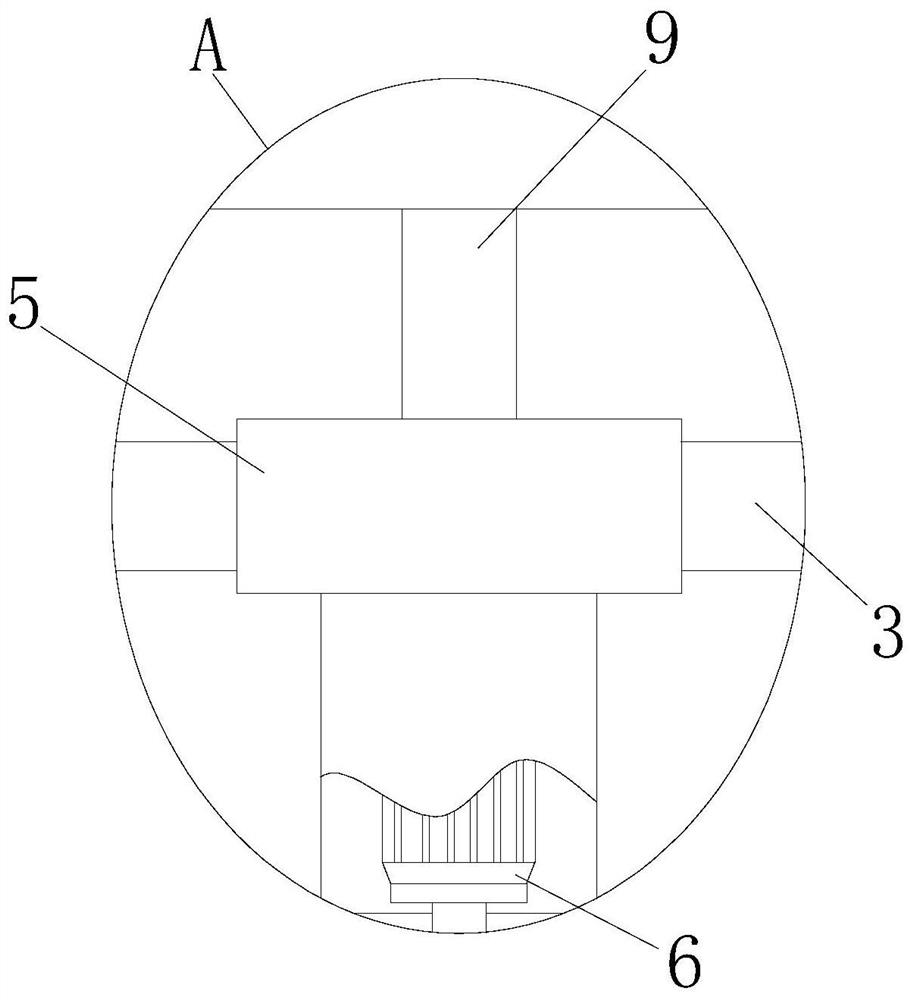

[0024] The thinning mechanism includes a threaded rod 3, a threaded barrel 5, a thinning motor 6, a carrier plate 10 and a multi-stage electric push rod 11. A threaded rod 3 is rotatably installed between the two side plates corresponding to the thinning box 1, and the threaded rod 3 Two threaded barrels 5 are threadedly connected to the outer wall of the thinning box 1, a first slide rail 8 is fixedly installed on the bottom surface of the top plate of the thinning box 1, and two first slide blocks 9 are slidably installed inside the first slide rail 8. The bottoms of the blocks 9 are respectively fixedly connected to the tops of the corresponding threaded cylinders 5, the bottoms of the two threaded cylinders 5 are fixedly installed ...

Embodiment 2

[0030] according to Figure 1-4 , a semiconductor wafer thinning device with a dust processing function, comprising a thinning box 1 , a thinning mechanism and a collecting mechanism, both of which are fixedly installed in the thinning box 1 .

[0031] The collection mechanism includes a processing box 13, a fan 14, a storage box 15 and a micro water pump 17. The processing box 13 is fixedly installed on the top surface of the bottom plate of the thinning box 1, and a fan 14 is fixedly installed inside the processing box 13. In the storage block 12, the air outlet end of the fan 14 is movably sleeved in the storage box 15, the storage box 15 is fixedly installed with a water storage box 16, and the top surface of the bottom plate of the water storage box 16 is fixedly installed with a micro water pump 17, and the micro water pump 17 The water outlet pipe runs through the bottom plate of the water storage box 16 and is fixedly sleeved with an atomizing nozzle 18 .

[0032] Whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com