Iron-nitrogen-carbon catalyst as well as preparation method and application thereof

An iron-nitrogen-carbon catalyst and catalyst technology, which can be applied to structural parts, electrical components, battery electrodes, etc., can solve the problems of poor electrocatalytic performance of iron-nitrogen-carbon catalysts, and achieve good oxygen reduction catalytic performance and stable physicochemical structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

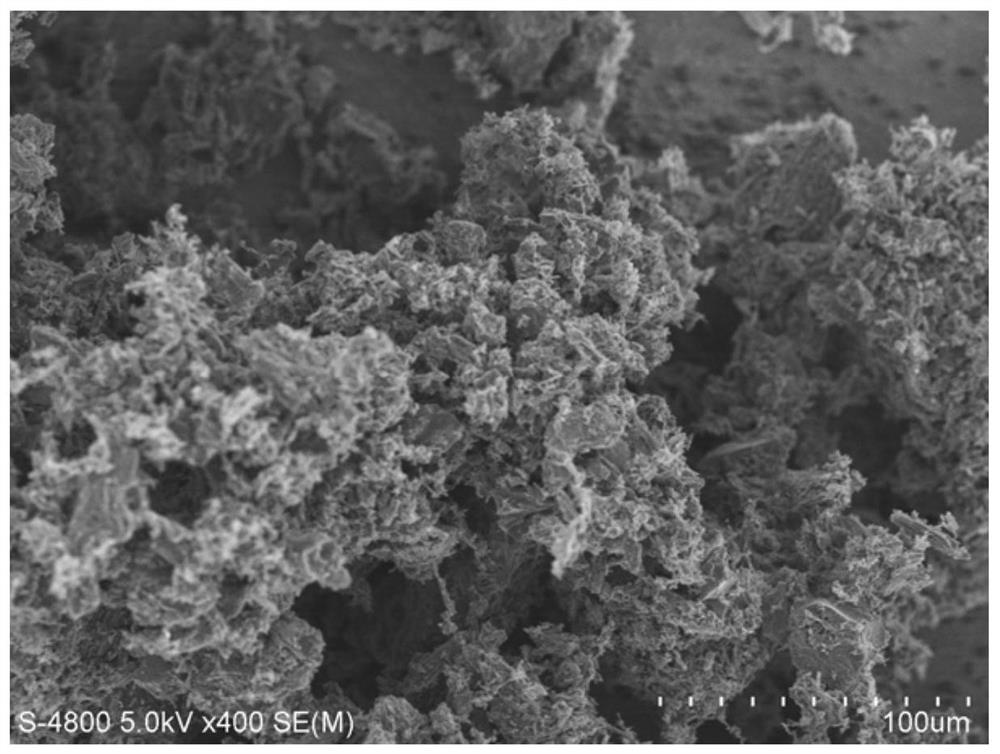

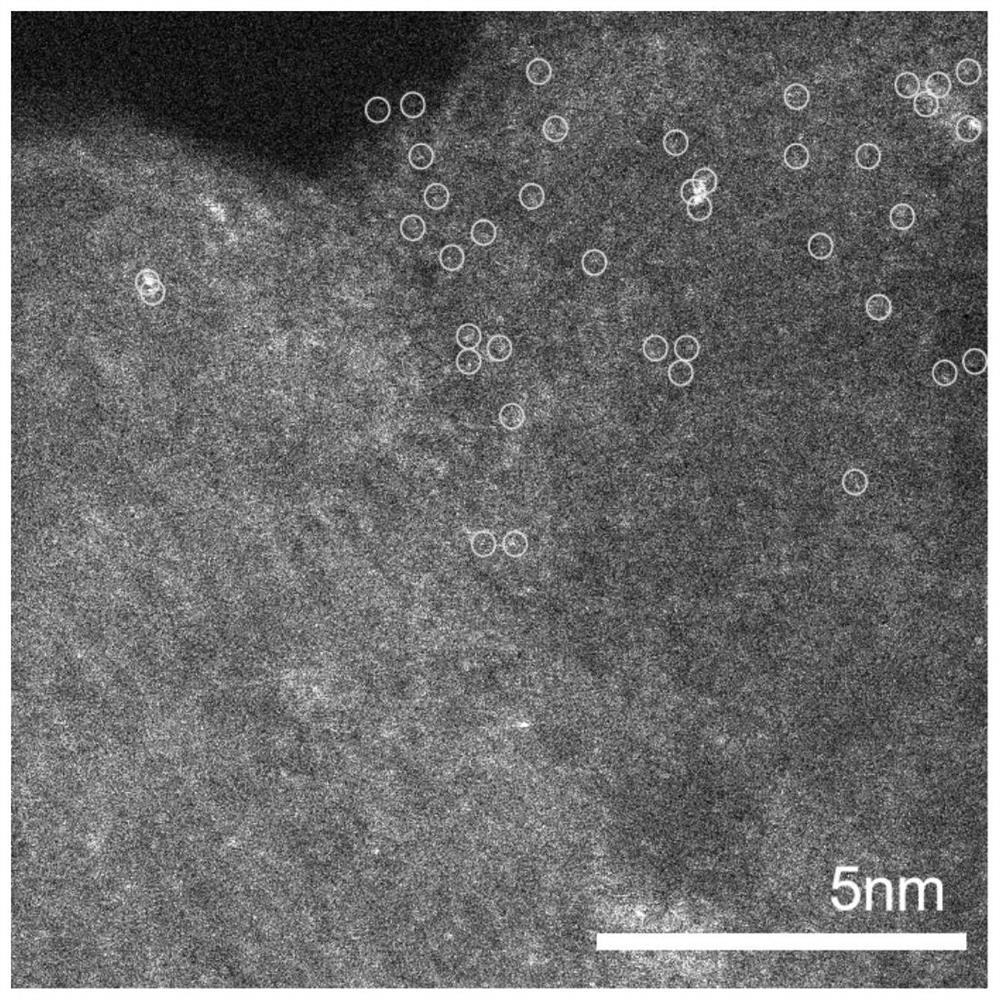

[0043]In order to overcome the above-mentioned problems existing in the preparation methods of the existing iron-nitrogen-carbon catalysts, a second aspect of the present disclosure provides a method for preparing the iron-nitrogen-carbon catalysts described in any one of the embodiments of the present disclosure, the method comprising: a, Mixing naphthalene with a nitrogen source and carrying out a polymerization reaction under the action of anhydrous ferric chloride to obtain a nitrogen-containing naphthalene pitch precursor, wherein the nitrogen source is an aromatic compound containing a nitrogen heterocycle; b. The nitrogen-naphthalene pitch precursor is subjected to high-temperature carbonization treatment under an inert gas atmosphere to obtain an intermediate; c. the intermediate is acid-washed to obtain an iron-nitrogen-carbon catalyst, wherein the acid used may include hydrochloric acid during the acid-washing , at least one of sulfuric acid and nitric acid, and the a...

Embodiment 1

[0053] This example is used to illustrate the iron-nitrogen-carbon catalyst of the present disclosure and its preparation method, and the preparation method includes the following steps:

[0054] (1) 10g naphthalene, nitrogen source (5g indole, 1g carbazole) and 4.5g anhydrous ferric chloride are placed in the reactor, and under nitrogen protection, react at 80° C. for 3 hours to obtain nitrogen-containing naphthalene pitch precursor body;

[0055] (2) Take 5 g of the nitrogen-containing naphthalene pitch precursor obtained in step (1) and place it in a tube furnace, and heat it up to 950° C. under a nitrogen atmosphere with a flow rate of 200 mL / min, and the heating rate is 5° C. / min; , at a constant temperature for 2 hours; after the constant temperature treatment, the temperature was lowered to room temperature under nitrogen protection, and the cooling rate was 5 °C / min; after the cooling, the calcined product was taken out to obtain an intermediate;

[0056] (3) grinding...

Embodiment 2

[0065] A preparation method of an iron-nitrogen-carbon catalyst, comprising the following steps:

[0066] (1) 10g of naphthalene, nitrogen source (3g of pyrrole, 4g of carbazole) and 2.5g of anhydrous ferric chloride were placed in a reactor, and under nitrogen protection, reacted at 80° C. for 3 hours to obtain a nitrogen-containing naphthalene pitch precursor ;

[0067] (2) Take 5 g of the nitrogen-containing naphthalene pitch precursor obtained in step (1) and place it in a tube furnace, and heat it up to 900° C. under a nitrogen atmosphere with a flow rate of 100 mL / min, and the heating rate is 5° C. / min; , at a constant temperature for 2 hours; after the constant temperature treatment, the temperature was lowered to room temperature under nitrogen protection, and the cooling rate was 5 °C / min; after the cooling, the calcined product was taken out to obtain an intermediate;

[0068] (3) grinding the intermediate obtained in step (2), adding 150mL 2mol / L hydrochloric acid ...

PUM

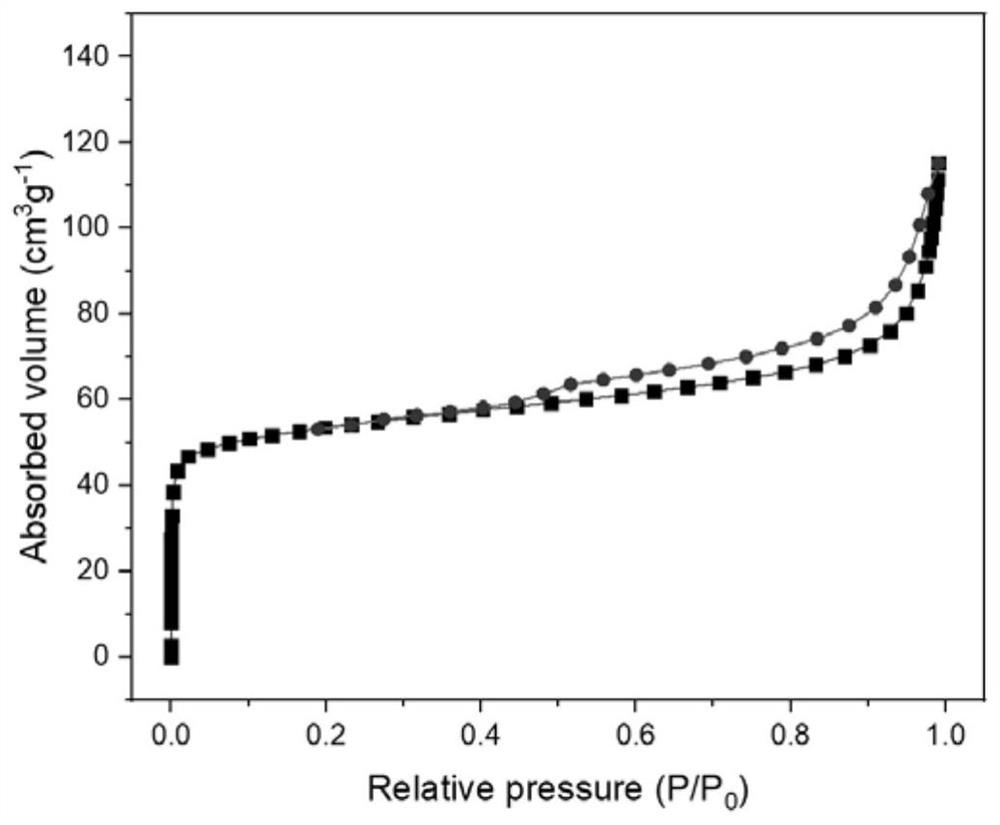

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com