A preparation method and application of trace boron-doped cobalt oxyhydroxide

A cobalt oxyhydroxide, boron doping technology, applied in chemical instruments and methods, oxidized water/sewage treatment, metal/metal oxide/metal hydroxide catalysts, etc., can solve the complex preparation process, limited catalytic activity, problems such as low catalytic efficiency, to achieve the effect of enriching active sites and stabilizing the physical and chemical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

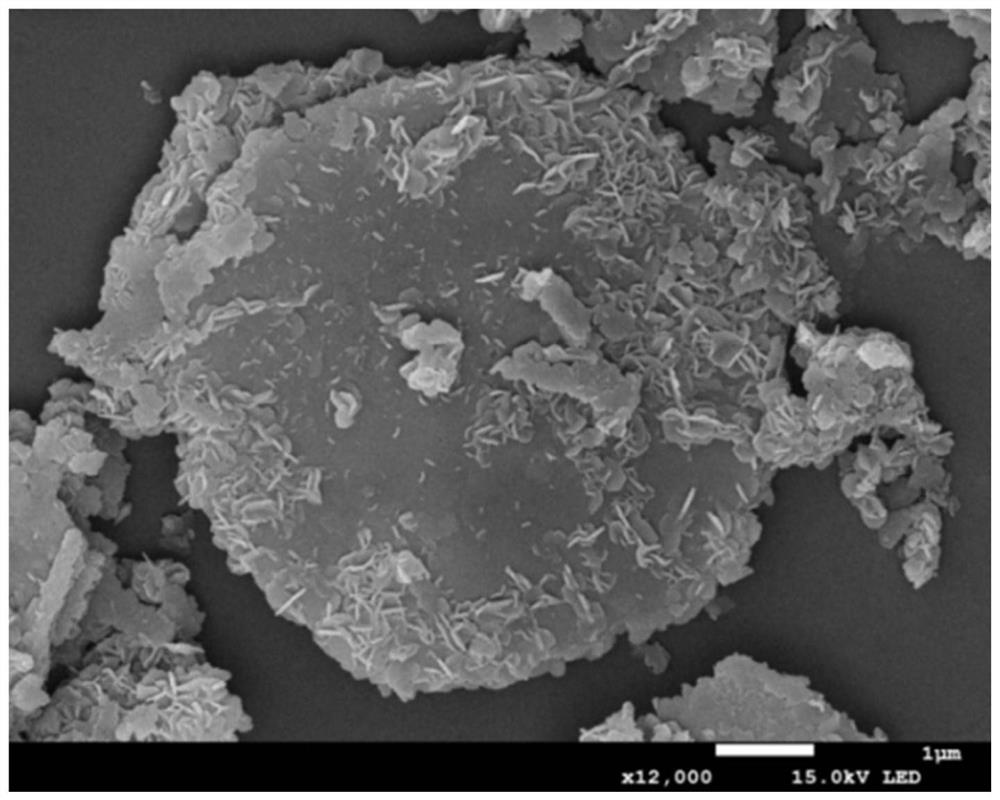

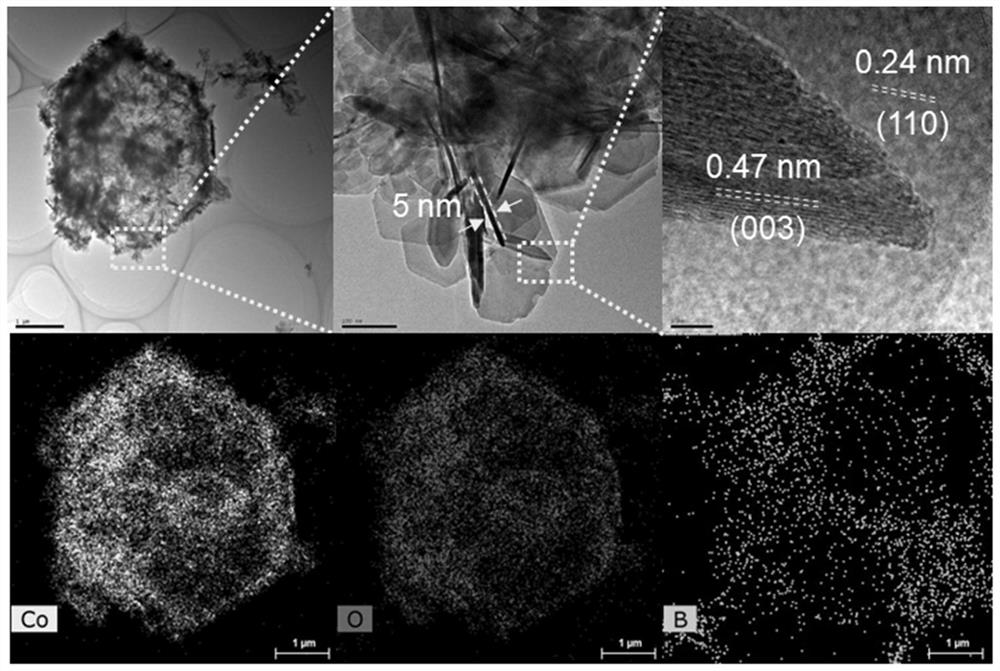

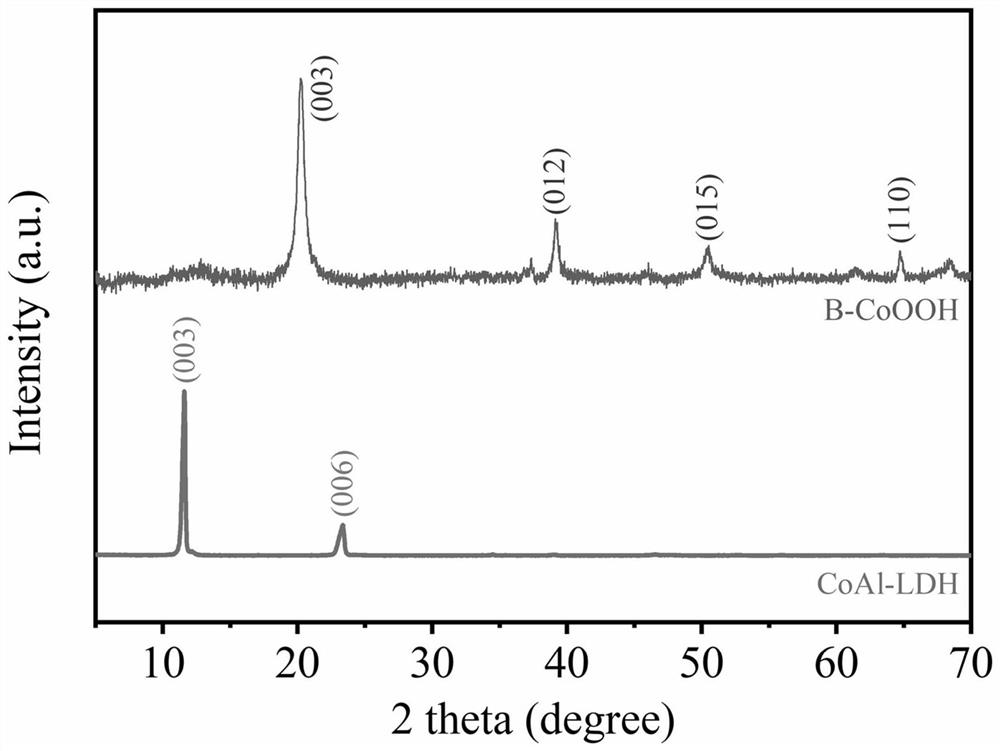

[0041] In this example, the preparation method of trace boron-doped cobalt oxyhydroxide (B-CoOOH) is as follows:

[0042] Mix 0.260 g of cobalt nitrate, 0.034 g of aluminum nitrate and 0.270 g of urea in 100 mL of ultrapure water, sonicate for 10 minutes, and then condense and reflux in an oil bath at 97 °C for 3 hours. After alternately rinsing with pure water, dry at 60°C to obtain cobalt-aluminum hydrotalcite powder, which is collected for future use. Take 0.02 g of the cobalt-aluminum hydrotalcite powder obtained above and disperse it in 8 mL of ultrapure water. After ultrasonication for 10 minutes, add 72 mL of a mixed solution containing 0.008 mol of sodium borohydride and 0.08 mol of sodium hydroxide, and stir magnetically at 30 °C for 12 hours, and then filtered to obtain a solid phase, washed and dried completely at 60°C to obtain a trace amount of boron-doped cobalt oxyhydroxide.

Embodiment 2

[0046]Using catalysts (divided into 4 groups according to the different types of catalysts, respectively using the B-CoOOH obtained in Example 1, the N-CoOOH obtained in Comparative Example 1, the CoOOH prepared by the traditional co-precipitation method, and the CoAl obtained by the method of Example 1 -LDH) to catalyze PMS to degrade PPCPs in water, the specific steps are as follows: Prepare the aqueous solution containing sulfamethoxazole as the solution to be treated (pH=7), the volume is 50mL, and the initial sulfamethoxazole concentration is 40 μM ( Among them, M is mol / L, μM is 10 -6 mol / L, mM is 10 -3 mol / L, the same below), add 5 mg of catalyst (mass concentration is 0.1g / L), and then add 0.3 mM PMS.

[0047] In addition, B-CoOOH and PMS were used alone to degrade the sulfamethoxazole in the above-mentioned solution to be treated as a control.

[0048] Related processing results such as Figure 4 with Figure 5 As shown, after 6 min of reaction, the removal rate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com