High-grafting active lignin as well as preparation method and application thereof

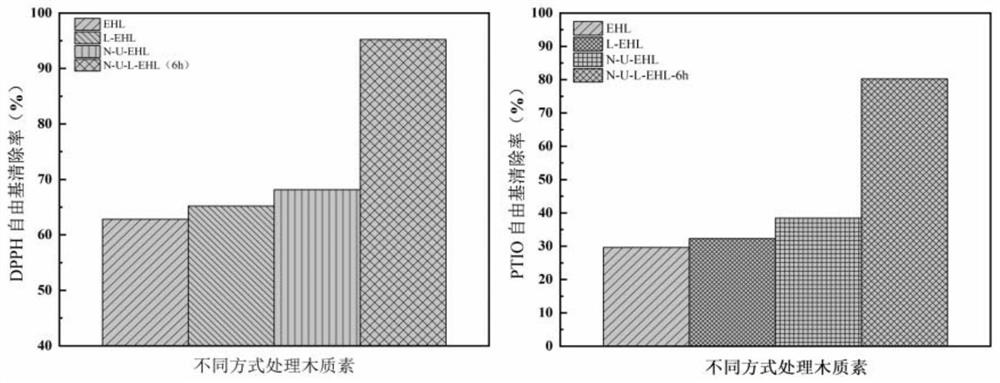

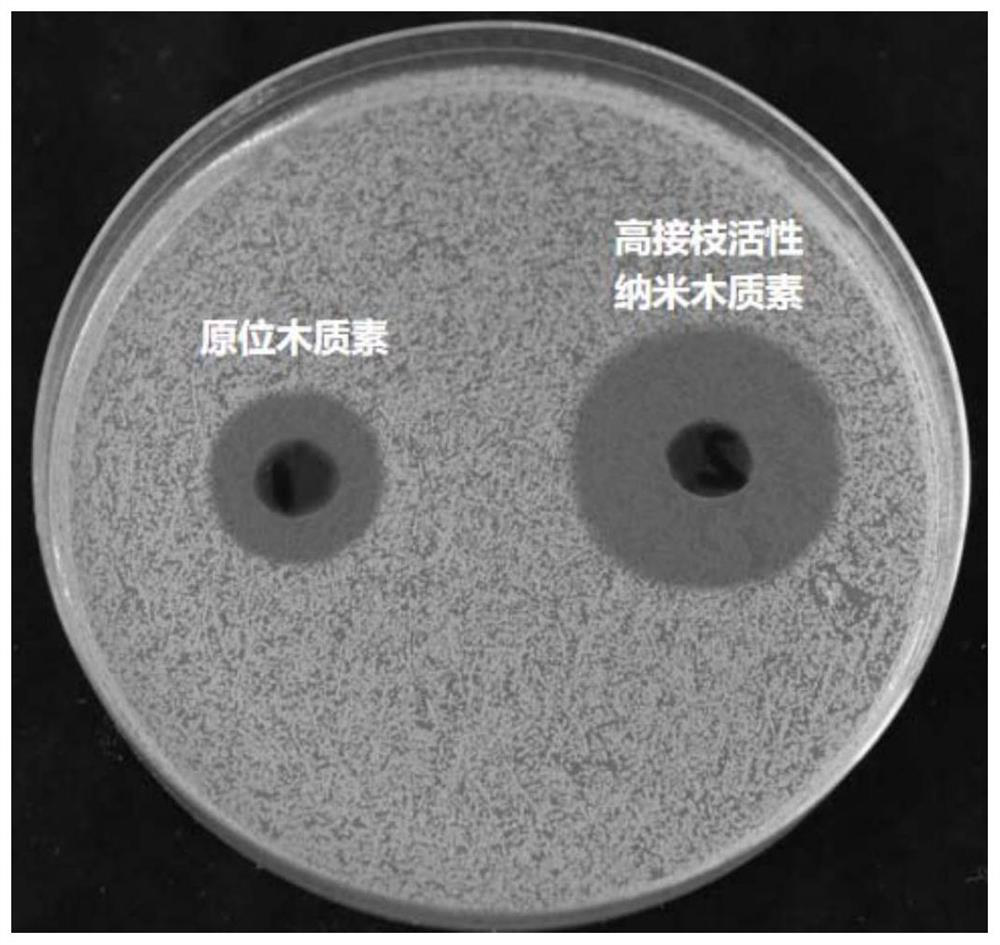

A lignin and high-grafting technology, applied in the direction of botany equipment and methods, applications, chemical instruments and methods, etc., can solve the problems of DNA damage to human immunity, induction of uterine fibroids, lung cancer, and lack of lignin particles , to achieve the effect of improving antioxidant capacity, reducing oxidative damage, and improving UV shielding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] A preparation method of high grafting activity lignin, the steps are as follows:

[0065] (1) Preparation of raw materials: in parts by weight, 100 parts of lignin, 2 parts of sodium hydroxide, 4 parts of urea, 800 parts of water, 2 parts of dilute hydrochloric acid with pH 2, 2 parts of laccase, and lemon with pH 2 800 parts of acid-sodium citrate buffer;

[0066] (2) Dissolving lignin in a sodium hydroxide / urea / water mixed solution at -20°C for 20 h to obtain a lignin mixed solution;

[0067] (3) add dilute hydrochloric acid dropwise to the lignin mixed solution obtained in step (2) at a speed of every drop (each drop is 0.6 ml) for three seconds to separate out lignin particles, and wash the lignin particles for 4 times. Dehydration after washing;

[0068] (4) putting the lignin particles washed and dehydrated in step (3) into a citric acid-sodium citrate buffer, adding laccase, and stirring at a rate of 800 r / min at 10° C. for 20 hours;

[0069] (5) washing and d...

Embodiment 2

[0073] A preparation method of high grafting activity lignin, the steps are as follows:

[0074] (1) Preparation of raw materials: in parts by weight, 100 parts of lignin, 6 parts of sodium hydroxide, 6 parts of urea, 1000 parts of water, 4 parts of dilute hydrochloric acid with pH 3, 20 parts of laccase, and lemon with pH 4 2000 parts of acid-sodium citrate buffer;

[0075] (2) Dissolving lignin in a sodium hydroxide / urea / water mixed solution at -10°C for 30 h to obtain a lignin mixed solution;

[0076] (3) add dilute hydrochloric acid dropwise to the lignin mixed solution obtained in step (2) at a speed of every drop (each drop is 1 ml) for five seconds to separate out lignin particles, and wash the lignin particles for 6 times, each time Dehydration after washing;

[0077] (4) putting the lignin particles washed and dehydrated in step (3) into a citric acid-sodium citrate buffer, adding laccase, and stirring at a rate of 1000 r / min at 35° C. for 15 h;

[0078] (5) washin...

Embodiment 3

[0082] A preparation method of high grafting activity lignin, the steps are as follows:

[0083] (1) Preparation of raw materials: in parts by weight, 100 parts of lignin, 8 parts of sodium hydroxide, 8 parts of urea, 1200 parts of water, 4 parts of dilute hydrochloric acid with pH 2, 8 parts of laccase, and acetic acid with pH 6 - 1000 parts of sodium acetate buffer;

[0084] (2) Dissolving lignin in a sodium hydroxide / urea / water mixed solution at 20°C for 12 h to obtain a lignin mixed solution;

[0085] (3) in the lignin mixed solution obtained in step (2), add dilute hydrochloric acid dropwise at a rate of every drop (each drop is 0.6 ml) for three seconds to separate out lignin particles, and wash the lignin particles for 6 times. Dehydration after washing;

[0086] (4) put the lignin particles washed and dehydrated in step (3) into a buffer solution, add laccase, and stir at a rate of 600 r / min at 50° C. for 12 h;

[0087] (5) washing and dehydrating the product of ste...

PUM

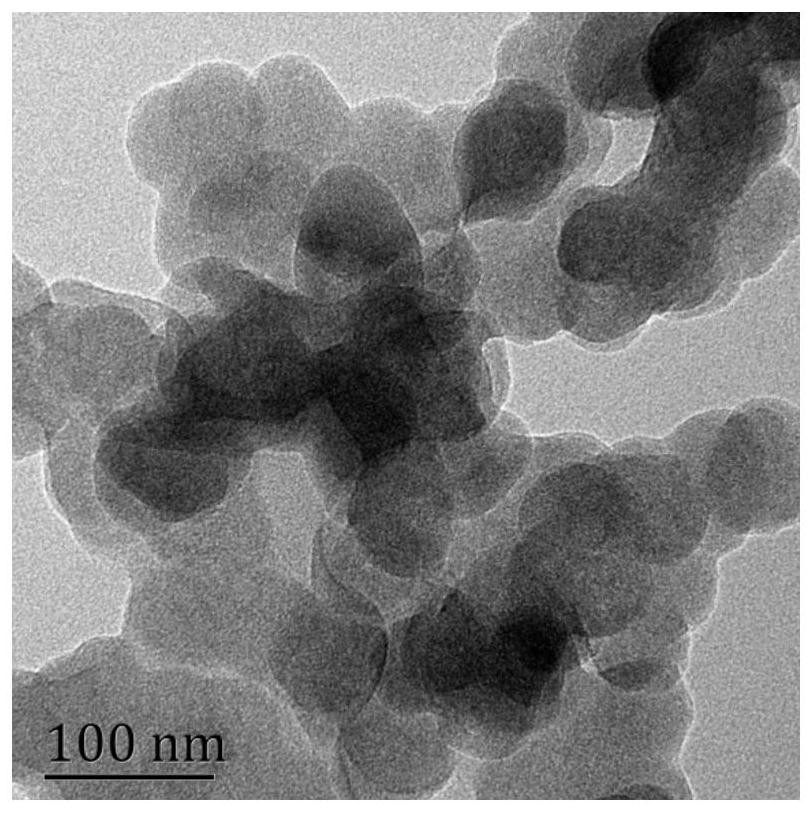

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com