Preparation method of integrated all-solid-state lithium battery structure

A lithium battery and all-solid-state technology, which is applied in the field of preparation of an integrated all-solid-state lithium battery structure, can solve problems such as lithium metal side reactions, poor interface contact between the positive electrode and the electrolyte, and low ion conductivity, so as to reduce interface impedance and improve Effect of Cycle Life and Energy Density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

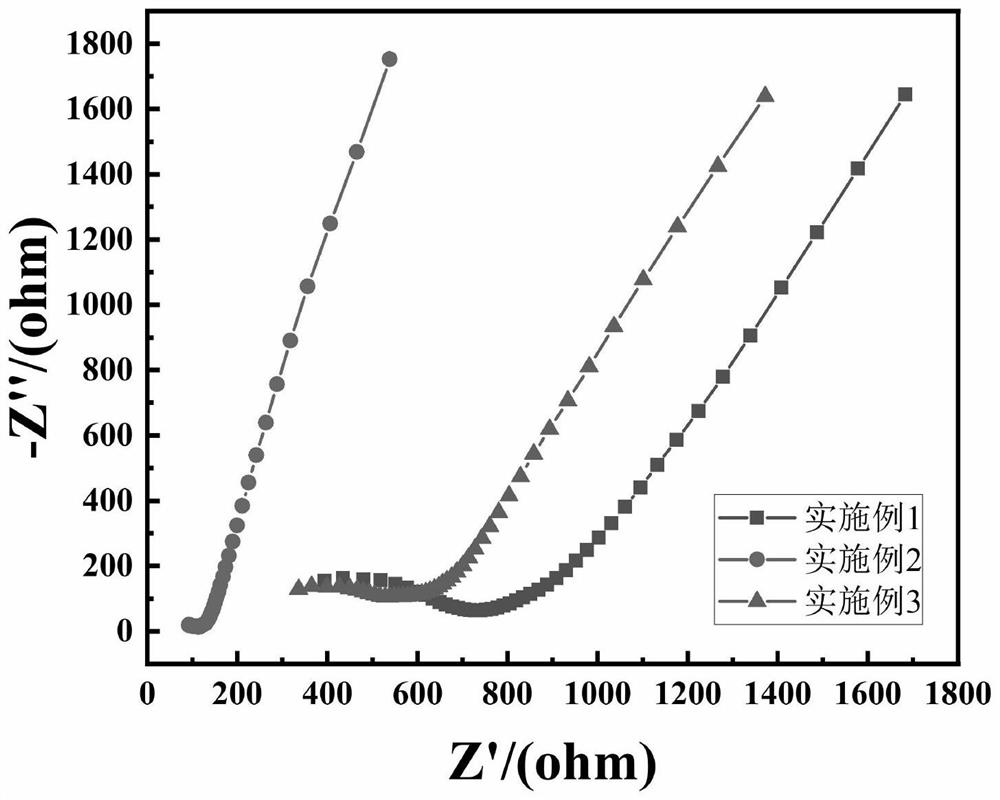

Embodiment 1

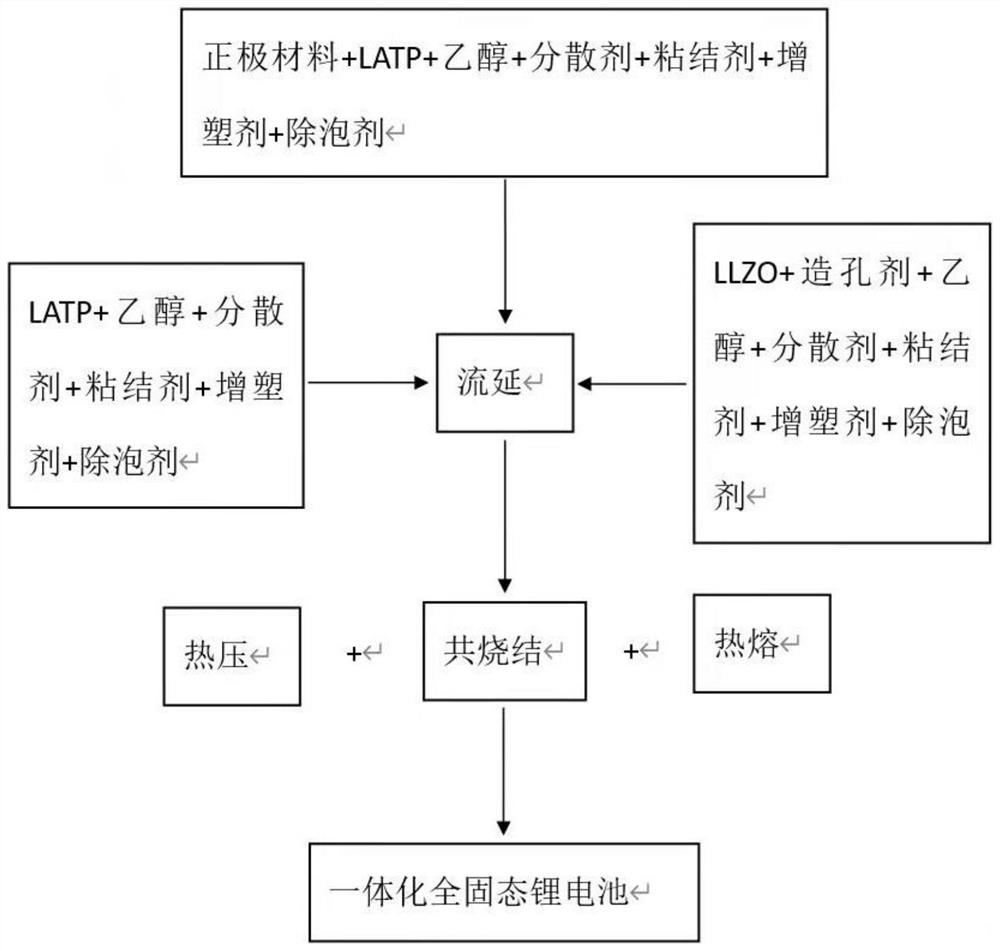

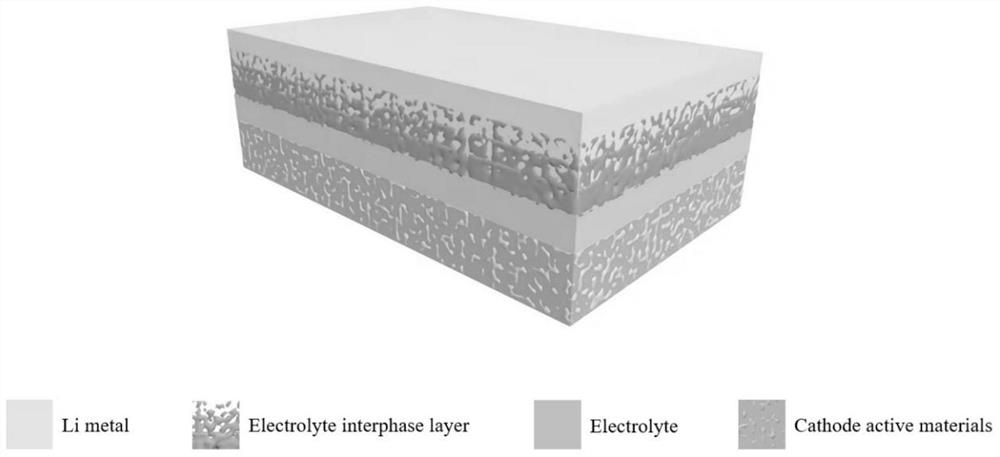

[0032] see Figure 1 to Figure 6 As shown, an integrated all-solid-state lithium battery structure and a preparation method thereof include the following steps:

[0033] Step1: Take LiFePO 4 Powder, LATP powder as raw material, LiFePO 4 The mass ratio to LATP is 7:3, add ethanol, triethanolamine dispersant, polyvinyl butyral binder, polyethylene glycol plasticizer, n-butanol defoamer, ball mill and mix for 24h, take out the casting, Dry to prepare composite electrode membrane green embryos;

[0034] Step2: Use LATP powder as raw material, add ethanol, triethanolamine dispersant, polyvinyl butyral binder, polyethylene glycol plasticizer, n-butanol defoamer, ball mill and mix for 24 hours, take out casting, dry , to prepare LATP membrane embryos;

[0035] Step3: Take LLZO powder as raw material, add 10%, 20%, 30% starch pore-forming agent to LLZO powder respectively, add ethanol, triethanolamine dispersant, polyvinyl butyral binder, polyethylene glycol Plasticizer and n-but...

Embodiment 2

[0040] An integrated all-solid-state lithium battery structure and a preparation method thereof, comprising the following steps:

[0041] Step1: Take Li 3 V 2 (PO 4 ) 3 Powder, LATP powder as raw materials, Li 3 V 2 (PO 4 ) 3 The mass ratio to LATP is 8:2, add ethanol, triethanolamine dispersant, polyvinyl butyral binder, polyethylene glycol plasticizer, n-butanol defoamer, ball mill and mix for 24h, take out the casting, Dry to prepare composite electrode membrane green embryos;

[0042] Step2: Use LATP powder as raw material, add ethanol, triethanolamine dispersant, polyvinyl butyral binder, polyethylene glycol plasticizer, n-butanol defoamer, ball mill and mix for 24 hours, take out casting, dry , to prepare LATP membrane embryos;

[0043] Step3: Take LLZO powder as raw material, add 15%, 25%, 35% starch pore-forming agent to LLZO powder respectively, add ethanol, triethanolamine dispersant, polyvinyl butyral binder, polyethylene glycol Plasticizer, n-butanol defo...

Embodiment 3

[0048] An integrated all-solid-state lithium battery structure and a preparation method thereof, comprising the following steps:

[0049] Step1: Take LiCoO 2 Powder, LATP powder as raw material, LiCoO 2 The mass ratio with LATP is 9:1, add ethanol, triethanolamine dispersant, polyvinyl butyral binder, polyethylene glycol plasticizer, n-butanol defoamer, ball mill and mix for 24h, take out the casting, Dry to prepare composite electrode membrane green embryos;

[0050] Step2: Use LATP powder as raw material, add ethanol, triethanolamine dispersant, polyvinyl butyral binder, polyethylene glycol plasticizer, n-butanol defoamer, ball mill and mix for 24 hours, take out casting, dry , to prepare LATP membrane embryos;

[0051] Step3: Take LLZO powder as raw material, add 20%, 30% and 40% starch pore-forming agent to LLZO powder respectively, add ethanol, triethanolamine dispersant, polyvinyl butyral binder, polyethylene glycol Plasticizer, n-butanol defoaming agent, ball milled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com