Preparation method of TNBA/TNAZ eutectic mixture

A technology of eutectics and injectors, which is applied in the direction of nitrated acyclic/alicyclic/heterocyclic amine explosive compositions, offensive equipment, explosives processing equipment, etc., can solve the problems of difficult control of eutectic particle size, solvent waste, Environmental protection and other issues, to achieve the effect of easy operation, process simplification, and reduction of heating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

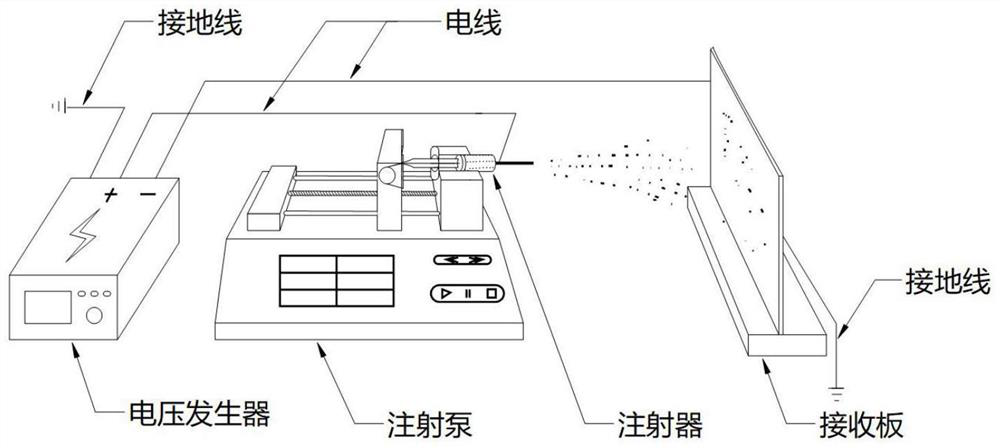

[0033] This embodiment relates to the preparation of a eutectic with a mass ratio of TNBA / TNAZ of 1:9, see figure 1 shown, the specific steps are as follows:

[0034] At room temperature, 2,4,6-trinitro-3-bromoanisole and 1,3,3-trinitroazetidine were added to 5.08 mL of acetone as an organic solvent to prepare the mass fraction as a 20% solution. Wherein: the mass ratio of TNBA and TNAZ is 1:9, and the total mass is 1g;

[0035] After withdrawing the precursor solution with a 10 ml syringe with a 20G stainless steel flat-tipped needle, the syringe was placed in the syringe pump. Connect the voltage generator, the positive terminal is connected to the needle, and the negative terminal is connected to the receiver board. Cover the receiving plate with tin foil at 13kV, 4.8ml / h injection rate and 15cm to receive the product; after drying, the eutectic can be obtained.

Embodiment 2

[0037] This embodiment relates to the preparation of a eutectic with a mass ratio of TNBA / TNAZ of 3:7, see figure 1 shown, the specific steps are as follows:

[0038] At room temperature, 2,4,6-trinitro-3-bromoanisole and 1,3,3-trinitroazetidine were added to 3.81 mL of acetone as an organic solvent, and the mass fraction was 25% solution. Wherein: the mass ratio of TNBA and TNAZ is 3:7, and the total mass is 1g;

[0039] After withdrawing the precursor solution with a 5 ml syringe with a 20G stainless steel flat-tipped needle, the syringe was placed in the syringe pump. Connect the voltage generator, the positive terminal is connected to the needle, and the negative terminal is connected to the receiver board. The product was received by covering the receiving plate with tin foil at 11 kV voltage, 4.5 mL / h injection rate and 13 cm. The eutectic is obtained after drying.

Embodiment 3

[0041] This embodiment relates to the preparation of a eutectic with a mass ratio of TNBA / TNAZ of 5:5, see figure 1 shown, the specific steps are as follows:

[0042] At room temperature, 2,4,6-trinitro-3-bromoanisole and 1,3,3-trinitroazetidine were added to 4.44 mL of acetone as an organic solvent, and the mass fraction was 30% solution. Wherein: the mass ratio of TNBA and TNAZ is 5:5, and the total mass is 1.5g;

[0043]After withdrawing the precursor solution with a 5ml syringe with a 19G stainless steel flat-tipped needle, place the syringe in the syringe pump. Connect the voltage generator, the positive terminal is connected to the needle, and the negative terminal is connected to the receiver board. The product was received by covering the receiving plate with tin foil at 9 kV, 4 mL / h injection rate and 12 cm. The eutectic is obtained after drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com