Resin colloid repair material and repair method of cracked and damaged reinforced concrete structure

A resin colloid and repair material technology, applied in epoxy resin glue, adhesive, building maintenance and other directions, can solve the problems of insecure repair effect, high cost, structural damage, etc., to improve durability, wide application range, The effect of reducing the concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

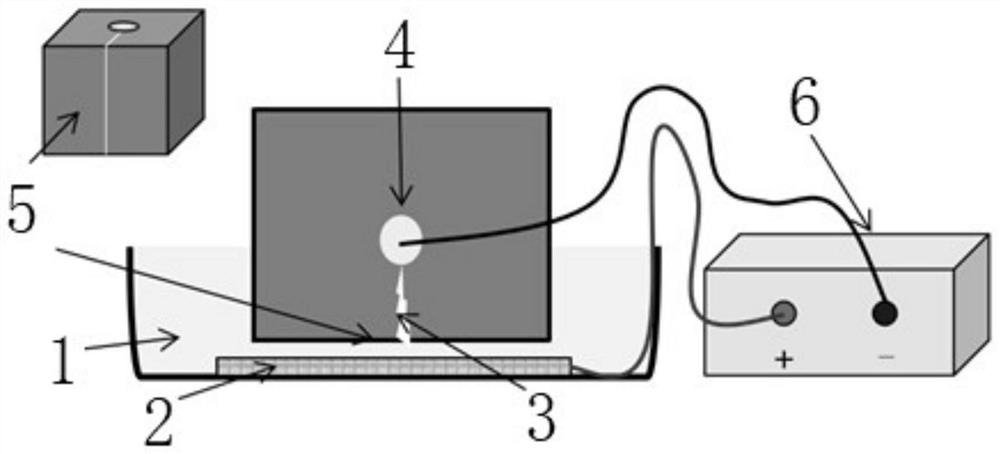

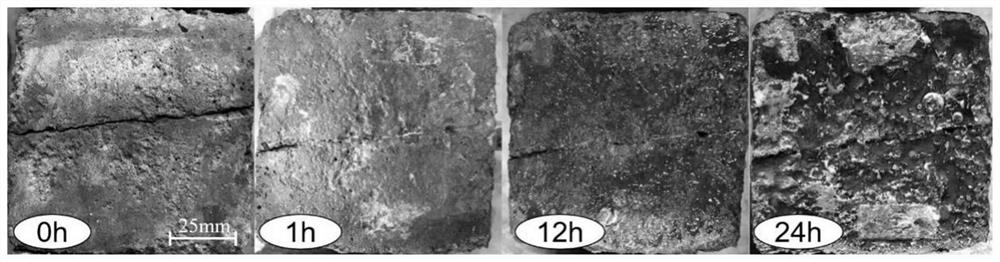

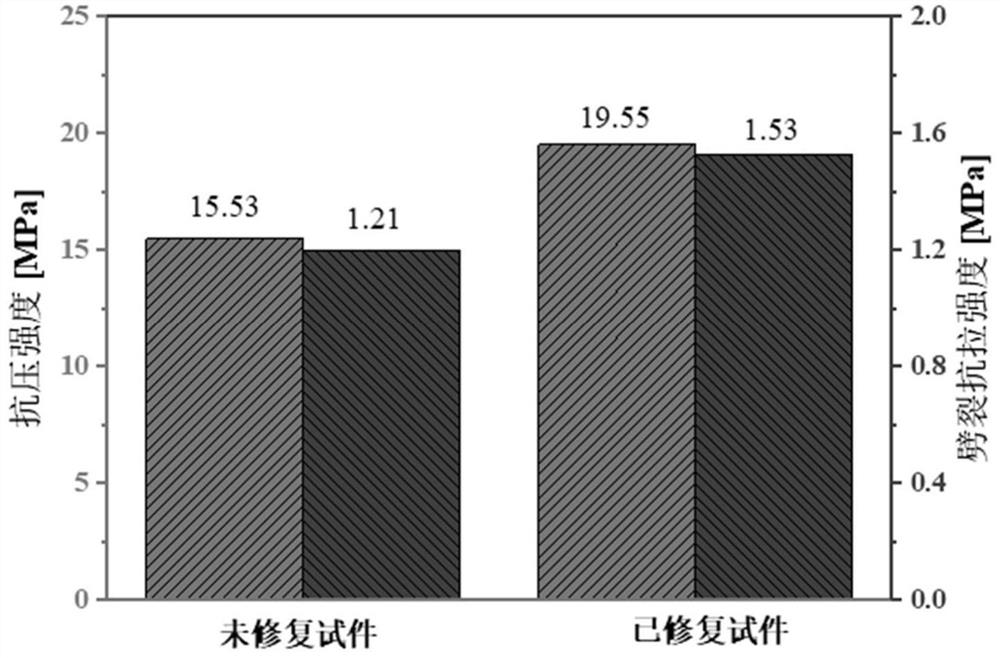

Method used

Image

Examples

preparation example Construction

[0056] The preparation method of the water-based cationic resin is as follows: after stirring and preheating the base resin, adding an alcohol amine, then heating up to carry out a modification reaction to obtain a modified epoxy resin; adding an organic acid after cooling down, and carrying out a protonation reaction to obtain a water-based cationic resin Cationic resin. The preheating temperature is 50-60°C; the temperature of the modification reaction is 70-85°C, and the time is 2-4h; the temperature of the protonation reaction is 55-65°C, and the time is 30-60min; the base resin, alcoholamine, The molar ratio of the organic acid is 1:(0.6-1.5):(0.3-1.4).

[0057] When preparing the water-based cationic resin curing agent, the molar ratio of enamine, base resin and end-capping agent is (2-2.6):(1-1.3):(2-2.6); the temperature of addition reaction is 60-80℃ , the time is 3-5h; the temperature of the end-capping reaction is 60-80 ℃, and the time is 3-5h.

[0058] In the res...

Embodiment 1

[0063] A high-performance resin colloid repair material, the preparation method of which is as follows:

[0064] 1. Synthesis of cationic epoxy resin

[0065] In a four-necked flask equipped with a stirrer, a condenser, a constant pressure funnel, and a thermometer, add bisphenol A epoxy resin E44, stir and preheat at 50-60°C, slowly drop diethanolamine, and heat up to 70- The modified epoxy resin was obtained after reacting at 85°C for 2-4 hours. Then, the temperature is lowered to 60°C, and organic acids (eg, glacial acetic acid, itaconic acid, maleic acid) are added to neutralize and form salts. After 30-60 minutes of reaction, a transparent colloid is obtained, which is a water-based cationic epoxy resin. The molar ratio of bisphenol A epoxy resin E-44, diethanolamine and organic acid is 1:0.6:0.3-1:1.5:1.4.

[0066] 2. Synthesis of cationic epoxy resin curing agent

[0067] Using enamine (such as diethylenetriamine, triethylenetetramine, tetraethylenepentamine) and bis...

Embodiment 2

[0071] A high-performance resin colloid repair material, the preparation method of which is as follows:

[0072] 1. Synthesis of cationic epoxy resin

[0073] In a four-necked flask equipped with a stirrer, a condenser, a constant pressure funnel, and a thermometer, add bisphenol A epoxy resin E51, stir and preheat at 50-60 ° C, slowly drop diethanolamine, and heat up for a period of reaction Modified epoxy resin is obtained after time. Then cool down to 60 ℃, add organic acid to neutralize and form salt (neutralization degree is not higher than 90%), and obtain transparent colloid after 30 minutes of reaction, which is water-based cationic epoxy resin, bisphenol A epoxy resin E51, diethanolamine, The molar ratio of the organic acid is 1:0.6:0.3-1:1.5:1.4.

[0074] 2. Synthesis of cationic epoxy resin curing agent

[0075] Using enamine and E51 as raw materials, the reaction temperature is 60-80 °C, and the reaction time is 3-5 h to synthesize the enamine epoxy resin adduct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com