Three-dimensional network polymer for adhesive and preparation method thereof

A three-dimensional network and polymer technology, applied in the direction of adhesives, adhesive types, epoxy glue, etc., can solve the problems of low dimensional stability, affecting applications, high water absorption, etc., to reduce interaction and promote linking ability , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

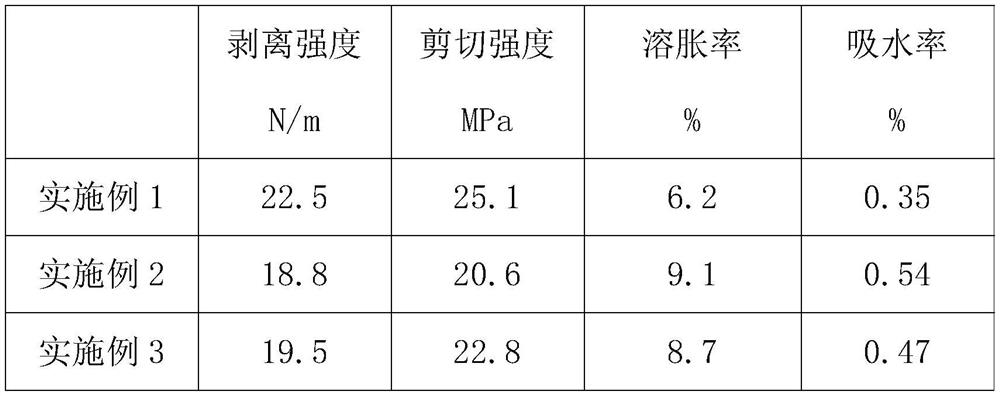

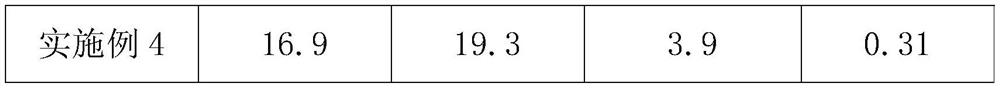

Embodiment 1

[0043] Embodiment 1 provides a three-dimensional network polymer for adhesive, and the preparation raw materials include: Polyimide (PI) powder, epoxy compound, and auxiliary agent.

[0044] The Polyimide (PI) powder is prepared from the following raw materials: 2.46 g of aromatic compound, 18.6 g of first carboxylic acid anhydride, 14.64 g of amino compound, 9.84 g of second carboxylic acid anhydride, 300 g of first solvent, 300 g of second solvent, and dehydrating agent 200g.

[0045] The aromatic compound is 1,3,5-triaminobenzene.

[0046] The first carboxylic anhydride is 4,4'-biphenyl ether dianhydride.

[0047] The amino compound is 3,5-bis(trifluoromethyl)-1,2-phenylenediamine.

[0048] The second carboxylic anhydride is 3-hydroxyphthalic anhydride.

[0049] The first solvent is N-methyl-2-pyrrolidone (NMP).

[0050] The second solvent is lignin.

[0051] The epoxy compound is a bisphenol F type epoxy resin.

[0052] The bisphenol F type epoxy resin was purchased ...

Embodiment 2

[0063] Example 2 provides a three-dimensional network polymer for an adhesive, and the specific implementation is the same as that of Example 1, except that the aromatic compound is p-methylphenethylamine.

Embodiment 3

[0065] Example 3 provides a three-dimensional network polymer for an adhesive, and the specific implementation is the same as that of Example 1, except that the amino compound is m-phenylenediamine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com