Self-bias photoelectric detector and preparation method and application thereof

A photodetector and self-bias technology, which is applied in the field of photodetectors, can solve the problems of low photodetector responsivity, low photocurrent intensity, and self-bias photodetectors do not have photocurrent gain. High light extraction efficiency, good photosensitive characteristics, and the effect of improving the photoelectric response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

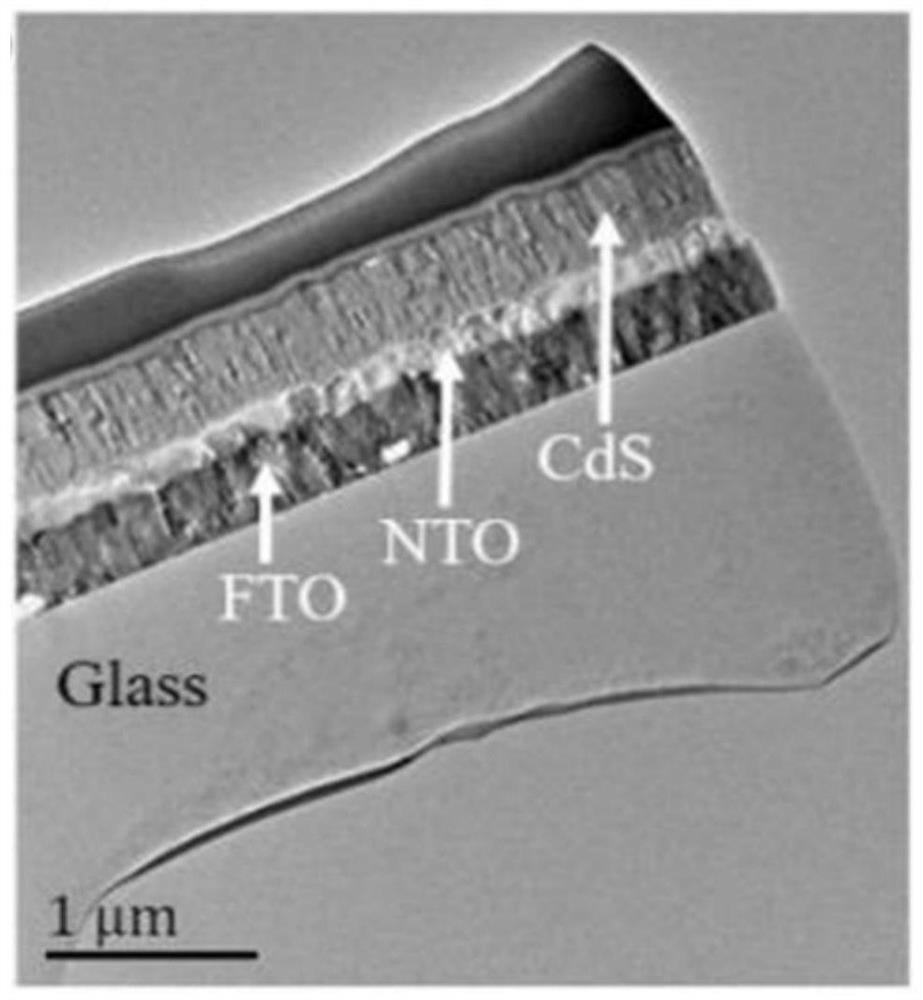

[0029] In the self-biased photodetector of this example, the substrate is FTO conductive glass. Niobium-doped titanium oxide film and CdS film are prepared by sputtering on the FTO conductive glass. Finally, silver paste is printed as the electrode to make the self-biased photodetector of this example. Piezoelectric photodetectors. The specific preparation method is as follows:

[0030] 1. Immerse the FTO conductive glass with acetone, alcohol and deionized water in sequence, and then perform ultrasonic cleaning on the soaked FTO conductive glass.

[0031] 2. Niobium-doped titanium oxide films were prepared on FTO conductive glass by vacuum sputtering method, where the pressure of the sputtering chamber was 0.3Pa, the atmosphere of the sputtering chamber was argon, the substrate temperature was 25°C, and the sputtering power was 5W , the deposition rate is 10 nm / min, and the sputtering time is 30 minutes to prepare a niobium-doped titanium dioxide film with a thickness of 300...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com