Preparation method of quantum dot light-emitting diode

A quantum dot light-emitting and diode technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as affecting the optoelectronic performance and working life of devices, and achieve the effect of optimizing injection balance, improving recombination efficiency, and improving EQE.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

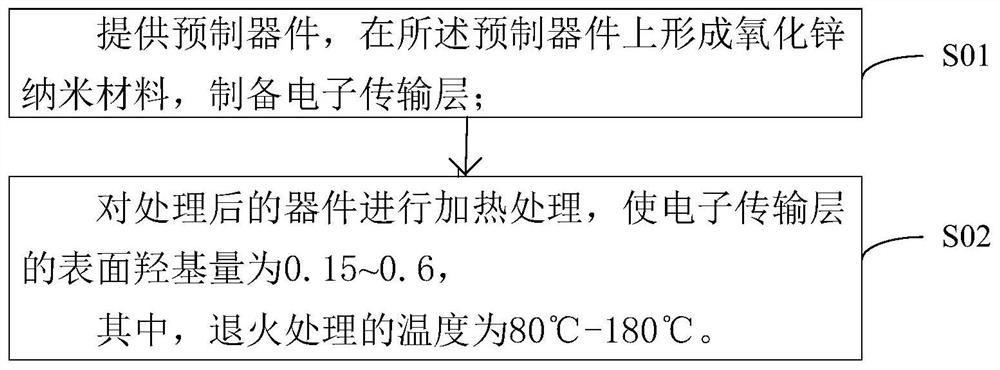

[0015] like figure 1 As shown, an embodiment of the present application provides a method for preparing a quantum dot light-emitting diode, comprising the following steps:

[0016] S01. provide a prefabricated device, form a zinc oxide nanomaterial on the prefabricated device, and prepare an electron transport layer;

[0017] S02. The treated device is subjected to heat treatment so that the amount of hydroxyl groups on the surface of the electron transport layer is 0.15-0.6.

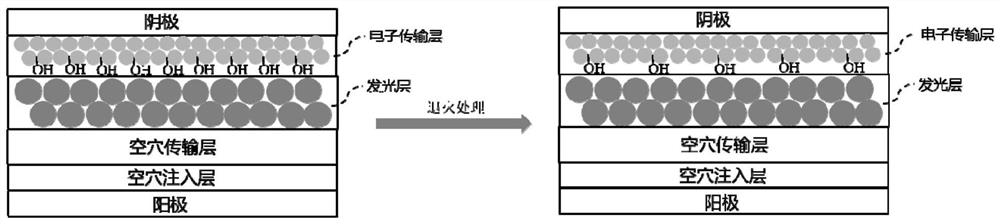

[0018] In the method for preparing a quantum dot light-emitting diode provided by the embodiments of the present application, the amount of hydroxyl groups on the surface of the electron transport layer is regulated by heating a device prepared with an electron transport layer, thereby reducing the amount of hydroxyl groups on the surface of the zinc oxide of the electron transport layer to the light-emitting layer of the quantum dots. Fluorescence quenching, at the same time, heat treatment can reduce...

Embodiment 1

[0044] A preparation method of a quantum dot light-emitting diode, comprising:

[0045] PEDOT:PSS was spin-coated on the anode ITO to prepare a hole injection layer; TFB was spin-coated on the hole-injection layer to prepare a hole-transport layer; CdZnSe / ZnSe / ZnS red quantum dots were spin-coated on the hole-transport layer to prepare A quantum dot light-emitting layer; spin-coating ZnO with a surface hydroxyl amount of 0.9 on the quantum dot light-emitting layer to prepare an electron transport layer; vapor-depositing Al to prepare a cathode, and packaging to form a quantum dot electroluminescent device.

[0046] The well-packaged devices were placed on a 150°C hot plate for 10 min to heat treatment.

[0047] When the quantum dot light-emitting diode is prepared by the method provided in Example 1, the schematic diagram of the change of hydroxyl groups in the electron transport layer before and after heating is as follows: figure 2 shown.

Embodiment 2

[0051] A preparation method of a quantum dot light-emitting diode, which is different from Example 1 is: spin-coating ZnO with a surface hydroxyl content of 0.7 on the quantum dot light-emitting layer to prepare an electron transport layer; placing the well-packaged device at 100 Bake on a ℃ hot plate for 20 min for heat treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com