Composite material, preparation method thereof and light-emitting diode

A composite material and compound technology, applied in the fields of light-emitting diodes, composite materials and preparation methods thereof, can solve the problems of easy agglomeration of nano-zinc oxide particles, and achieve the effects of improving carrier transport capacity, reducing agglomeration and reducing surface contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

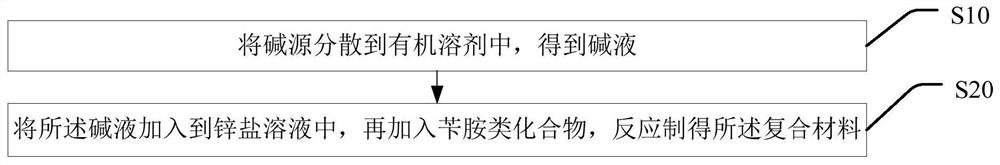

[0075] 1. The preparation steps of the composite material are as follows:

[0076] 01. First, add an appropriate amount of zinc acetate into 50ml of ethanol solution to prepare a 1M zinc acetate ethanol solution, and stir and dissolve at 70°C to obtain precursor solution 1;

[0077] 02. Weigh potassium hydroxide by Zn and OH-mol ratio of 1:1.5, add potassium hydroxide to 50ml of ethanol solution, prepare a 1.5M potassium hydroxide solution, and obtain precursor solution 2 after stirring and dissolving;

[0078] 03. Inject Precursor Solution 1 into Precursor Solution 2 at an injection rate of 10 mL / min. Then use magnetic stirring. After 30min, add benzylamine liquid, the molar ratio of benzylamine and Zn salt is 20:1, and heat to 50°C with magnetic stirring until the solution is completely clear;

[0079] 04. Wash the prepared solution to obtain a composite material solution.

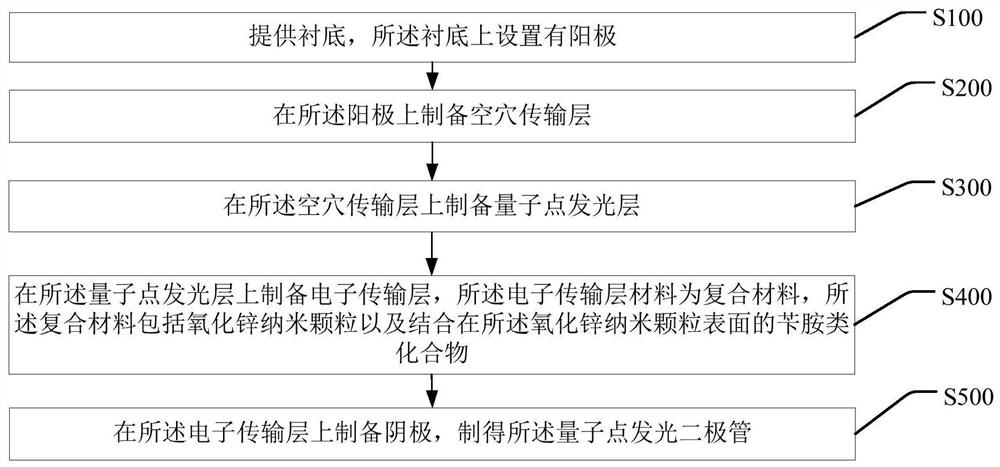

[0080] 2. The preparation steps of the QLED device with the upright structure are as follows:

[...

Embodiment 2

[0087] 1. The preparation steps of the composite material are as follows:

[0088] 01 First, add an appropriate amount of zinc acetate to 50ml of ethanol solution to prepare a 1M zinc acetate ethanol solution, and stir and dissolve at 70°C to obtain precursor solution 1;

[0089] 02. Weigh sodium hydroxide according to the mol ratio of Zn and OH- being 1:1.3, add sodium hydroxide to 50ml of ethanol solution, prepare a 1.3M potassium hydroxide solution, stir and dissolve to obtain precursor solution 2;

[0090] 03. Inject Precursor Solution 1 into Precursor Solution 2 at an injection rate of 5 mL / min. Then use magnetic stirring. After 30min, add tribenzylamine powder, the molar ratio of tribenzylamine to Zn salt is 30:1, and magnetic stirring at room temperature until the solution is completely clear;

[0091] 04. Cleaning the prepared solution to obtain a composite material solution;

[0092] 2. The preparation steps of the upright QLED device are as follows:

[0093] 07. ...

Embodiment 3

[0099] 1. The preparation steps of the composite material are as follows:

[0100] 01. First, add an appropriate amount of zinc acetate into 50ml of ethanol solution to prepare a 1M zinc acetate ethanol solution, and stir and dissolve at 70°C to obtain precursor solution 1;

[0101] 02. Weigh potassium hydroxide according to the mol ratio of Zn and OH- as 1:1.1, add sodium hydroxide to 50ml of ethanol solution, prepare a 1.1M potassium hydroxide solution, and obtain precursor solution 2 after stirring and dissolving;

[0102] 03. Inject Precursor Solution 1 into Precursor Solution 2 at an injection rate of 10 mL / min. Then use magnetic stirring. After 30min, add 3-phenylbenzylamine, the molar ratio of 3-phenylbenzylamine and Zn salt is 20:1, and magnetic stirring at room temperature until the solution is completely clear;

[0103] 04. Cleaning the prepared solution to obtain a composite material solution;

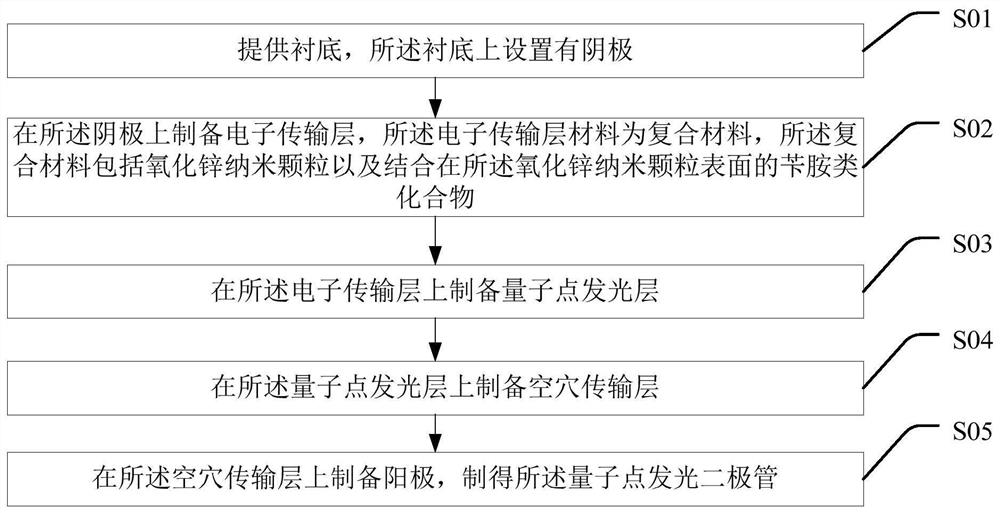

[0104] 2. The fabrication steps of the inverted QLED device are as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com