Separation and purification system and method for phenol and hydrogen peroxide hydroxylation reaction mixed liquid

A purification method and hydroxylation technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of high energy consumption of dehydration towers, hindered production, difficult discharge, etc., to reduce the difficulty of dephenolization and equipment Investment, reduce product energy consumption, good fluidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

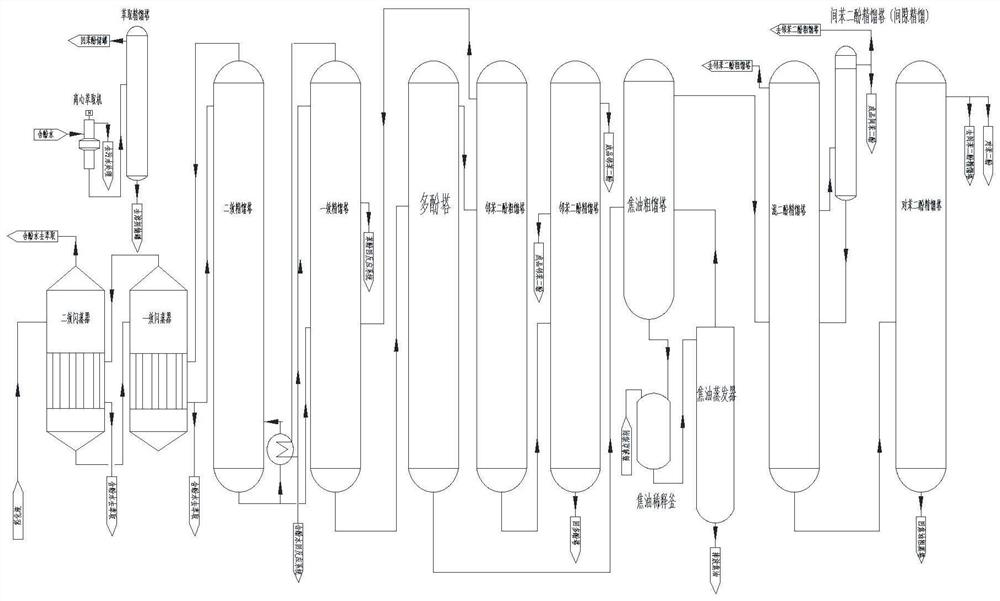

[0065] The composition of 57% phenol, 33% water, 6.2% catechol, 3.2% hydroquinone, 0.2% resorcinol, 0.4% tar raw material liquid is treated, see the treatment process figure 1 .

[0066] (1) Double-effect dehydration

[0067] The flow rate of 480Kg / h is sent to the double-effect dehydration flasher. The operating conditions of the double-effect dehydration flasher are the pressure of 30Kpa and the temperature of 70-80℃. , the residual liquid of the double-effect dehydration flasher is sent to the first-effect dehydration flasher, and the vaporized gas phase of the first-effect dehydration flasher material enters the double-effect dehydration flasher heater shell side. After condensation, an aqueous solution containing 7.8% phenol is obtained. The operating conditions of the first-effect dehydration flasher are the pressure of 50Kpa and the temperature of 80-90°C. The residual liquid of the first-effect dehydration flasher is sent to the second-effect dehydration tower, and th...

Embodiment 2

[0081] The composition of 39.4% phenol, 50% water, 3.0% catechol, 6.6% hydroquinone, 0.3% resorcinol, 0.7% tar raw material liquid is processed. For the processing flow, see figure 1 .

[0082] (1) Double-effect dehydration

[0083] The raw material liquid is sent to the double-effect dehydration flasher at a flow rate of 480Kg / h. The operating conditions of the double-effect dehydration flasher are the pressure of 30Kpa and the temperature of 70-80 °C. The residual liquid of the double-effect dehydration flasher is sent to the first-effect dehydration flasher, and the vaporized gas phase of the first-effect dehydration flasher enters the shell side of the double-effect dehydration flasher heater. After condensation, an aqueous solution containing 7.7% phenol is obtained. The operating conditions of the dehydration flasher are the pressure of 50Kpa and the temperature of 80-90℃. The residual liquid of the first-effect dehydration flasher is sent to the second-effect dehydrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com