Supported metallocene, catalyst containing supported metallocene, and preparation and application of supported metallocene

A metallocene, supported technology, applied in the direction of organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, organic chemistry, etc., can solve the problems of low selectivity, reduce the value of special solvent oil, etc., to achieve High selectivity, good load stability, and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

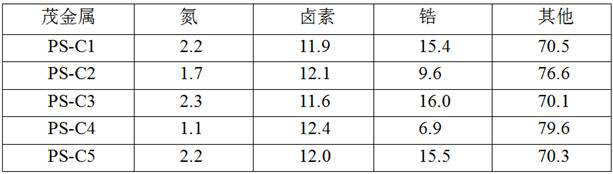

[0047] (1) Dissolve 10.5g of cyclopentadienopyrrole (105g / mol) in 105g of tetrahydrofuran, cool it to -40°C with a cold bath, and add 12.8g of n-butyllithium (64.05g / mol) dropwise to it ; Stir for 3.5 hours; add 22 g of chloromethyl polystyrene microspheres to the solution and stir for 10 hours;

[0048] (2) 6.6g of cyclopentadiene (66.1g / mol) was added to the above solution, and the stirring was continued for 8 hours;

[0049] (3) 11.3g of 1,3-dichloropropane (113g / mol) was then added dropwise to the solution, and the stirring was continued for 6 hours; then the product was filtered and washed three times with tetrahydrofuran to obtain modified resin microspheres PS-X;

[0050] (4) Add 40g PS-X to 160g tetrahydrofuran, cool it to -40°C with a cold tank, add 12.8g n-butyllithium dropwise thereto, and stir for 4 hours;

[0051] (5) Then, 23.3 g of zirconium tetrachloride (233 g / mol) was added thereto, followed by stirring for 12 hours. The product was then filtered, washed th...

Embodiment 2

[0053] (1) Dissolve 10.5 g of cyclopentadienopyrrole (105 g / mol) in 126 g of tetrahydrofuran, cool it to -40°C with a cold bath, and add 25 g of n-butyllithium (64.05 g / mol) dropwise thereto. Stir for 3 hours; add 44 g of chloromethyl polystyrene microspheres to the solution and stir for 6 hours;

[0054] (2) 13g of cyclopentadiene (66.1g / mol) was added to the above solution, and the stirring was continued for 10 hours;

[0055] (3) 22g 1,3-dichloropropane (113g / mol) was then added dropwise to the solution, and stirring was continued for 9 hours; then the product was filtered and washed with tetrahydrofuran 2 to obtain modified resin microspheres PS-X;

[0056] (4) Add 40g PS-X to 160g tetrahydrofuran, cool it to -40°C with a cold tank, add 20g n-butyllithium dropwise thereto, and stir for 3 hours;

[0057] (5) Then, 36.4 g of zirconium tetrachloride (233 g / mol) was added thereto and stirred for 24 hours; then the product was filtered, washed three times with dichloromethane,...

Embodiment 3

[0059] (1) 10.5g of cyclopentadienopyrrole (105g / mol) was dissolved in 42g of tetrahydrofuran, cooled to -40°C with a cold bath, and 9.6g of n-butyllithium (64.05g / mol) was added dropwise to it ; Stir for 4 hours; Add 11 g of chloromethyl polystyrene microspheres to the solution and stir for 8 hours;

[0060] (2) 6.6g of cyclopentadiene (66.1g / mol) was added to the above solution, and the stirring was continued for 5 hours;

[0061] (3) 9g of 1,3-dichloropropane (113g / mol) was then added dropwise to the solution, and stirring was continued for 9 hours; then the product was filtered and washed with tetrahydrofuran three times to obtain modified resin microspheres PS-X;

[0062] (4) Add 40g PS-X to 240g tetrahydrofuran, cool it to -40°C with a cold tank, add 8g n-butyllithium dropwise thereto, and stir for 3.5 hours;

[0063] (5) 11.6g of zirconium tetrachloride (233g / mol) was then added to it, and stirred for 18 hours; then the product was filtered, washed twice with dichlorom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com