Heating temperature control device of miniaturized mass spectrum ion source

A temperature control device and ion source technology, applied in the field of mass spectrometry analysis, can solve the problems of difficulty in studying high temperature pyrolysis reaction of solid substances, low thermal conductivity, low thermoelectric conversion efficiency, insufficient consideration in the selection of miniaturized pyrolysis furnaces, etc. The effect of flatness, less heat loss and high heat conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

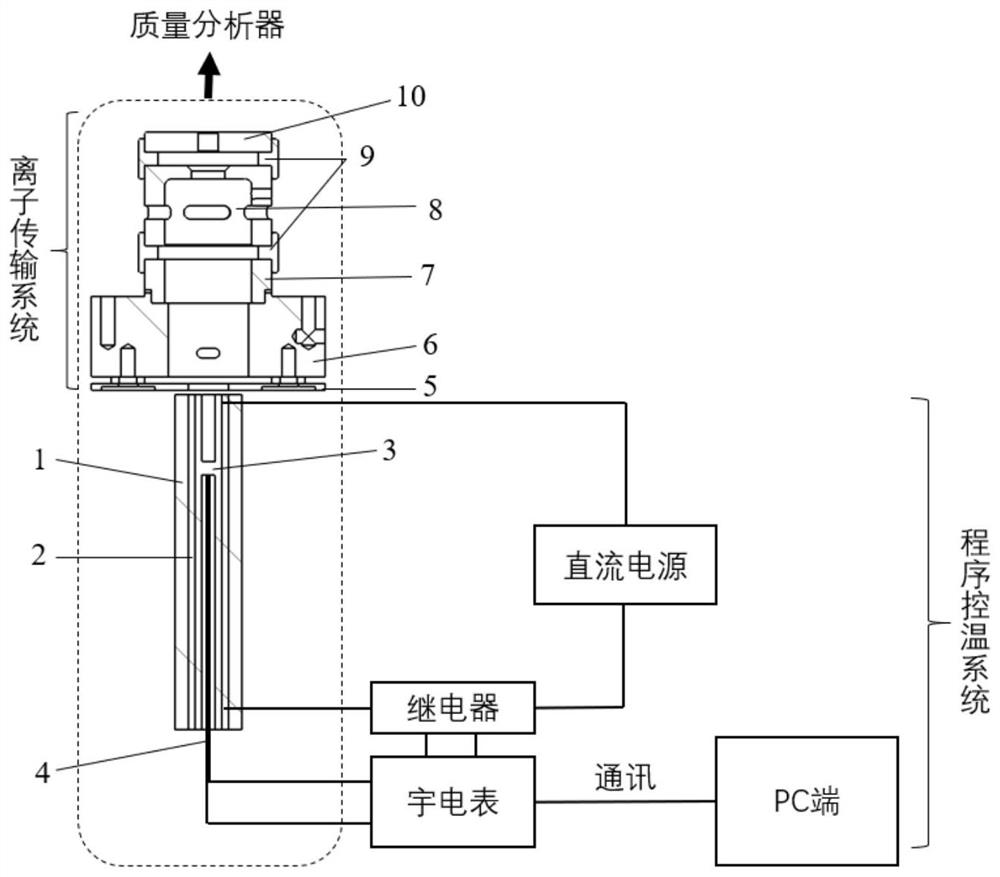

[0026] Attached to the following figure 1 This application will be described in further detail.

[0027] The embodiment of the present application discloses a heating and temperature control device for a miniaturized mass spectrometer ion source, which includes a vacuum chamber, a heating tube and an ion transmission system that are connected to each other are arranged in the vacuum chamber, and a program temperature control system is connected to the outside of the vacuum chamber, and the heating tube passes through The ceramic screw with low thermal conductivity is suspended and fixed on the base support rod of the vacuum chamber. Except for the screw fixing point, there is no contact point between the heating tube and other devices under vacuum, that is, there is no other heat transfer point, which minimizes heat loss (Fig. is not indicated).

[0028] The heating tube is composed of three layers: insulation layer 1, heating wire 2, and heat conduction tube 3. The insulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com