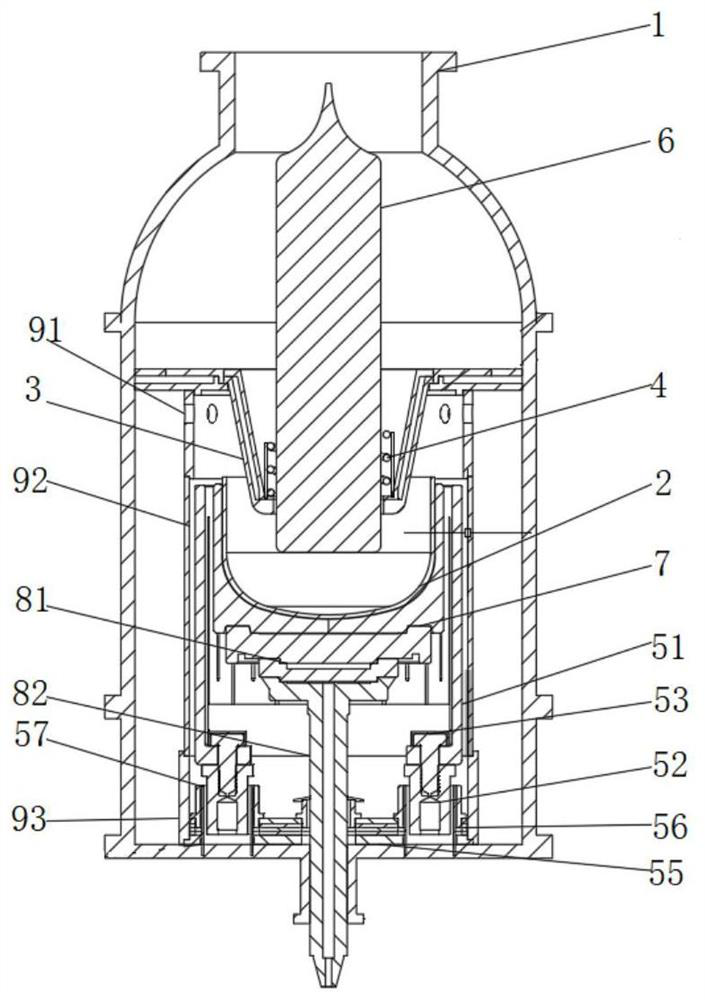

Indium antimonide crystal growth method and crystal growth furnace

A crystal growth furnace and crystal growth technology, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve problems affecting the quality of indium antimonide crystals and prone to thermal stress, so as to avoid heating, improve growth quality, The effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

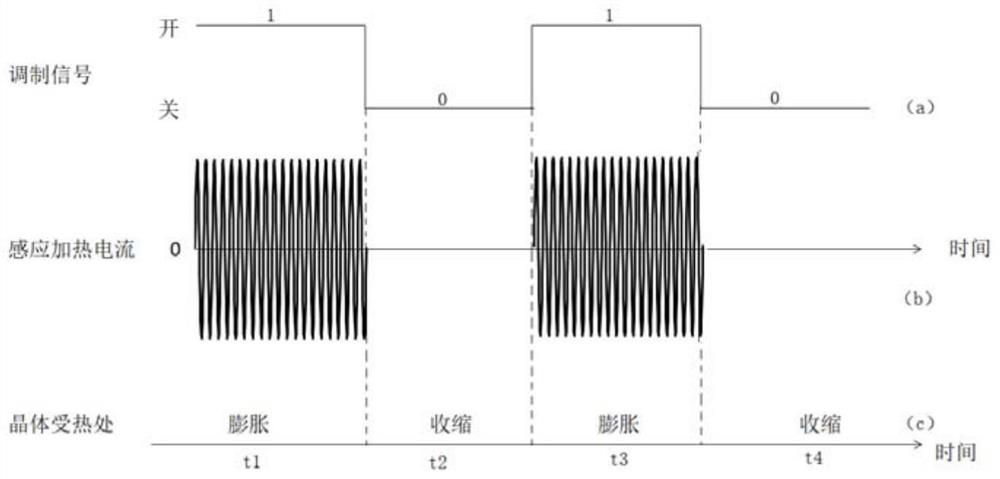

Method used

Image

Examples

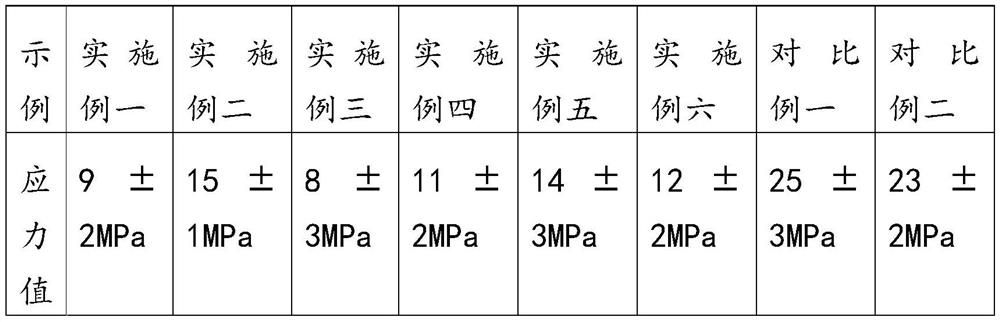

Embodiment 1

[0055] Example 1, the InSb polycrystalline raw material is heated to a temperature of 530° C., the rotation rate of the indium antimonide crystal is 7 rpm, the growth rate of the indium antimonide crystal is 16 mm / h, the growth diameter of the indium antimonide is 2 inches, and the electromagnetic induction heating The inner diameter of the coil is 2.5 inches, the induction frequency is 20Hz, the current is 1A, the modulation pulse frequency is 0.2Hz, and the duty cycle is 0.1. The total height of the electromagnetic induction heating coil is 30mm. After the growth length of the indium antimonide crystal exceeds the height of the heat shield mouth and reaches the height of the electromagnetic induction heating coil, electromagnetic induction heating is started until the growth of the indium antimonide crystal is completed. During the growth process of indium antimonide crystal, pure Ar gas protection gas is passed into the furnace body to prevent oxidation. The grown InSb cry...

Embodiment 2

[0056]Embodiment 2, the InSb polycrystalline raw material is heated to a temperature of 530° C., the speed range of indium antimonide crystal rotation is 7 rpm, the speed range of indium antimonide crystal growth is 14 mm / h, and the growth diameter of indium antimonide crystal is 3 inches. The inner diameter of the electromagnetic induction heating coil is 3.5 inches, the induction frequency is 100Hz, the current is 5A, the modulation pulse frequency is 0.8Hz, and the duty ratio is 0.3. The height of the electromagnetic induction heating coil is 50mm. After the crystal growth length exceeds the height of the heat shield mouth and reaches the height of the electromagnetic induction heating coil, the electromagnetic induction heating is started until the growth of the indium antimonide crystal is completed. During the growth process of indium antimonide crystal, pure Ar gas protection gas is passed into the furnace body to prevent oxidation. The grown InSb crystals were cut int...

Embodiment 3

[0057] Embodiment 3, the InSb polycrystalline raw material is heated to a temperature of 540° C., the rotation rate of the indium antimonide crystal is in the range of 10 rpm, and the growth rate of the indium antimonide crystal is in the range of 10 mm / h. The indium antimonide crystal growth diameter is 4 inches, and the inner diameter of the electromagnetic induction heating coil is 3.5 inches. The induction frequency is 200Hz, the current is 9A, the modulation pulse frequency is 5Hz, and the duty ratio is 0.1. The height of the electromagnetic induction heating coil is 100mm. After the growth length of the indium antimonide crystal exceeds the height of the heat shield mouth and reaches the height of the electromagnetic induction heating coil, electromagnetic induction heating is started until the growth of the indium antimonide crystal is completed. During the growth process of indium antimonide crystal, pure Ar gas protection gas is passed into the furnace body to preven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com