Transparent perovskite thin film transistor

A thin film transistor and perovskite technology, which is applied in the field of preparation of transparent perovskite thin film transistors, can solve the problems of difficulty in preparing transparent perovskite thin film transistors, inability to prepare single crystal devices in a large area, and limited application value. Achieve the effect of improving electron injection efficiency, simple substrate processing method, and good application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

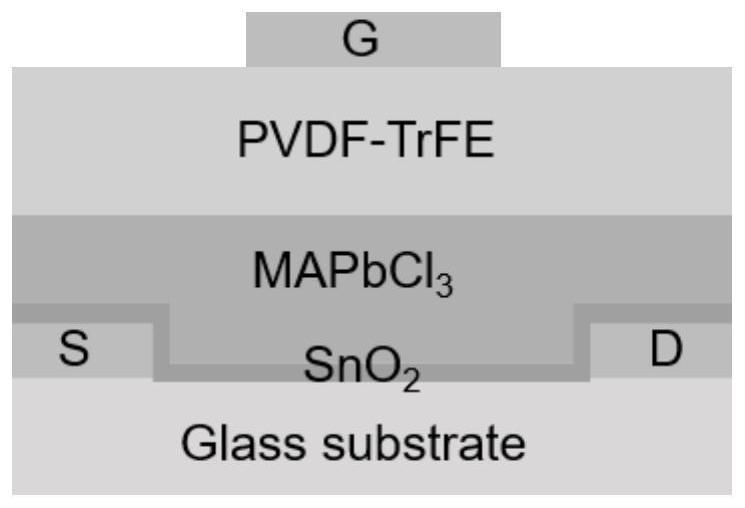

[0022] In this embodiment, a top-gate bottom-contact transistor is used as an example, and other bottom-gate top-contact, top-gate top-contact, and top-gate-bottom contact can be made into corresponding transistors only by changing the positions of the corresponding electrodes.

[0023] see figure 1 , a transparent perovskite thin film transistor includes a transparent substrate (glass), a source electrode (Cr), a drain electrode (Cr), a gate electrode (Al), an insertion layer (SnO 2 ), semiconductor layer (MAPbCl 3 ), a ferroelectric dielectric layer (PVDF-TrFE); the thickness of the insertion layer is 10 nm, and the thickness of the ferroelectric dielectric layer is 400 nm.

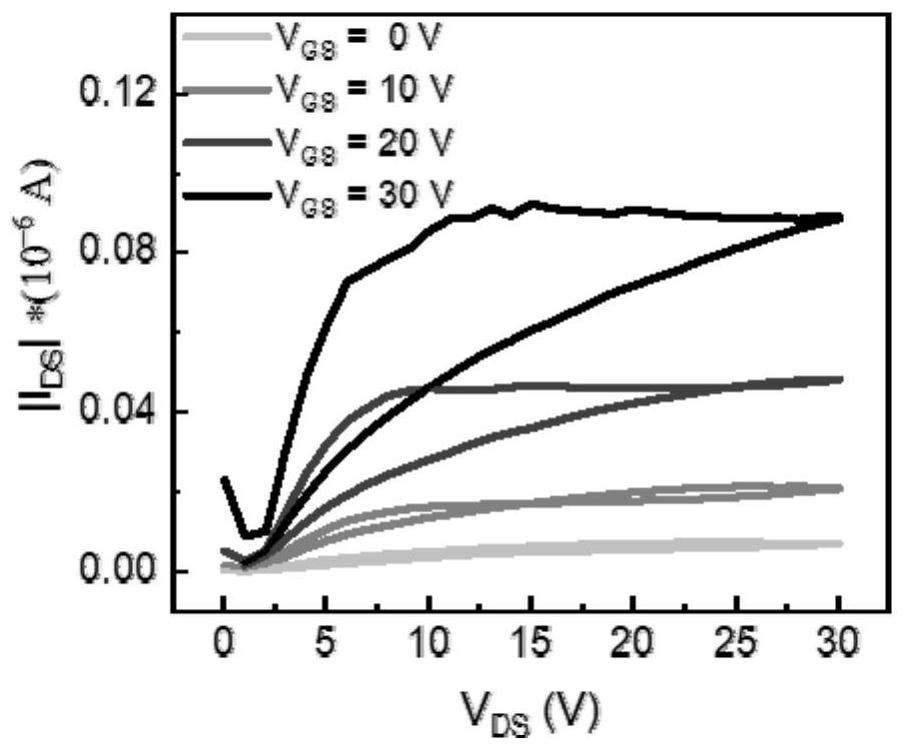

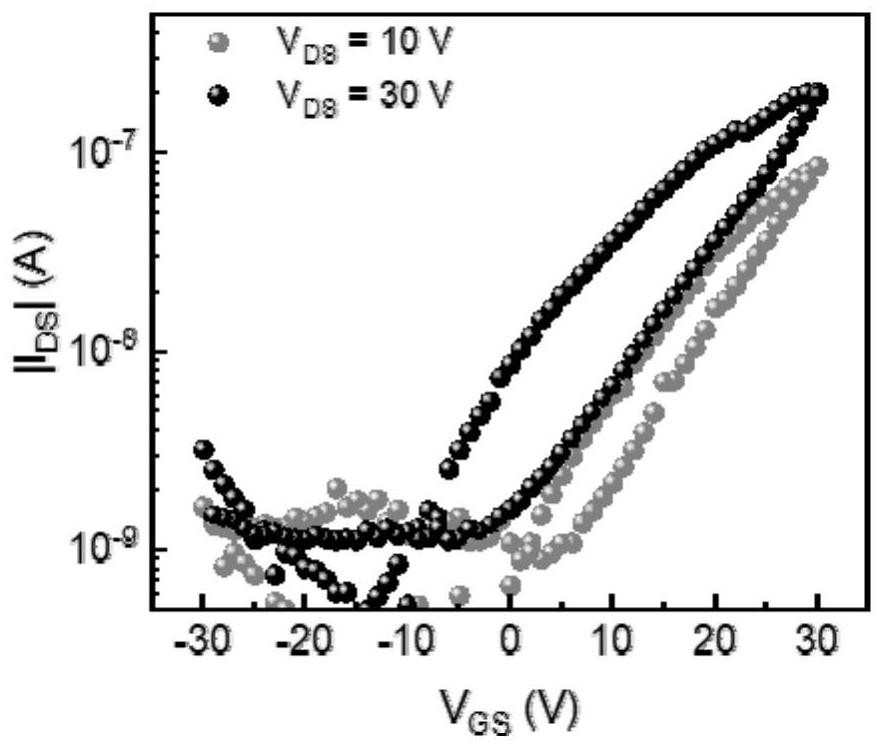

[0024] For transparent MAPbCl 3 Thin film transistor electrical testing, showing transistor output and transfer characteristics at room temperature, as shown in the appendix Figure 2-3 As shown, it can be seen from the transfer characteristic curve and the output characteristic curve that the transi...

Embodiment 2

[0026] Correspondingly, the present embodiment provides a method for preparing a transparent perovskite thin film transistor with a top-gate bottom-contact electrode. The method generally includes the following steps: using MAC1 and PbAc 2 It is a perovskite precursor liquid material, and PVDF-TrFE is a dielectric layer material to prepare a transparent perovskite thin film transistor. The specific steps are as follows:

[0027] Step 1: Process a transparent substrate with photolithographic electrodes; select a glass sheet with chrome-gold electrodes as the substrate. First, the glass slides were cleaned, followed by ultrasonic cleaning with deionized water, acetone and isopropanol for 1 min, and dried with an argon gun after cleaning. Then the glass sheet was transferred to an ozone treatment device for 15 min to change the wettability of the surface of the glass sheet.

[0028] Step 2: spin-coating the metal oxide solution, annealing at low temperature to form the intercala...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com