Application of metal tetraphenylporphyrin compound in electron transport material, quantum dot light-emitting device, preparation method of quantum dot light-emitting device and light-emitting device

An electron transport material, the technology of tetraphenylporphyrin, applied in the direction of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problem of reducing the energy level of the bottom conduction band of quantum dots, increasing the number of quantum dots and cathode electrons Potential barrier and other issues, to achieve the effect of improving life, reducing electron injection barrier, and reducing electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

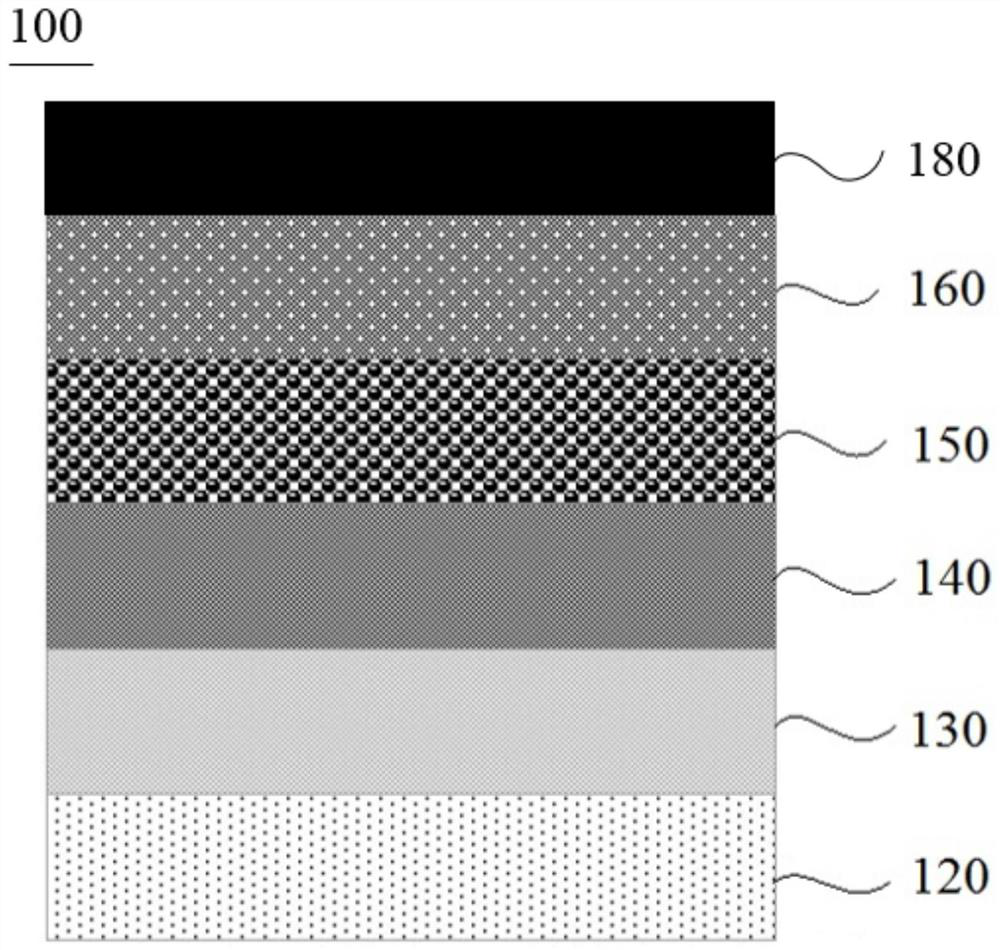

[0069] The preparation method comprises the following steps:

[0070] An anode is provided, and a quantum dot light-emitting layer is formed on the anode;

[0071] forming an electron transport layer on the quantum dot light-emitting layer;

[0072] forming a cathode on the electron transport layer;

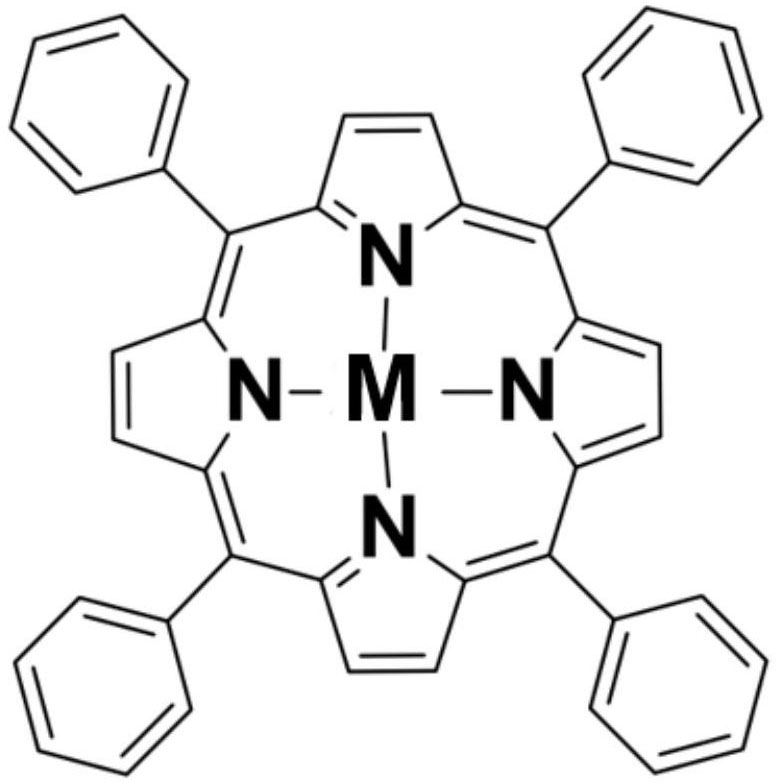

[0073] Wherein, the material forming the electron transport layer includes nano-ZnO and metal tetraphenylporphyrin complex mixed with each other; the metal elements in the metal tetraphenylporphyrin complex are selected from monovalent metal elements, divalent metal elements and One of the trivalent metal elements.

[0074] Specifically, the materials for each functional layer in the above quantum dot light-emitting device can be deposited by a solution method, spin coating, spray coating, inkjet printing and the like to form each functional layer.

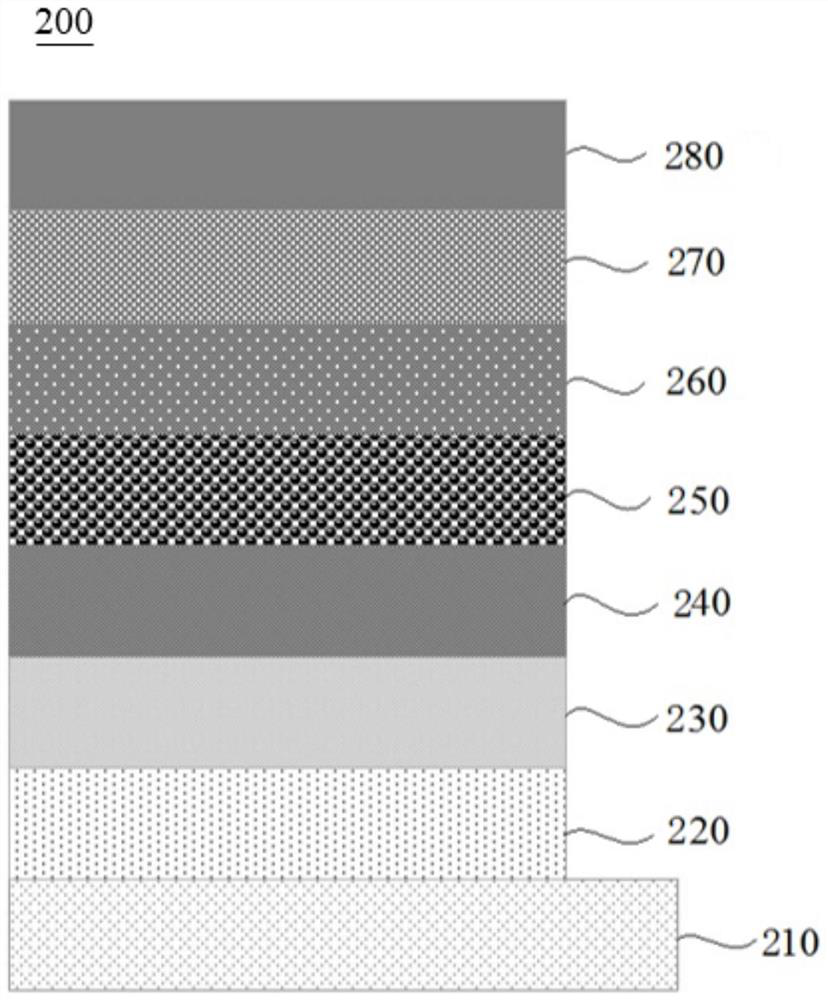

[0075] Another embodiment of the present invention provides a method for preparing the above-mentioned quantum dot light-emittin...

Embodiment 1

[0084] (1), using the transparent conductive thin film ITO as the anode, the thickness is 50nm.

[0085] (2) Deposit PEDOT:PSS as a hole injection layer on the anode by a solution method, with a thickness of 50 nm.

[0086] (3) Depositing TFB as a hole transport layer on the hole injection layer by a solution method, with a thickness of 30 nm.

[0087] (4) On the hole transport layer, ZnCdS / ZnS is deposited as a quantum dot light-emitting layer by a solution method, with a thickness of 25 nm.

[0088] (5), utilize solution method to deposit ZnO nanoparticle on quantum dot luminescent layer: porphyrin magnesium (represent the mixed solution of ZnO nanoparticle and porphyrin magnesium, the weight concentration ratio of ZnO nanoparticle and porphyrin magnesium in the solution is 90: 10) As an electron transport layer, the thickness is 50nm.

[0089] (6) Depositing Ag on the electron transport layer as a cathode with a thickness of 100 nm by vapor deposition.

Embodiment 2

[0091] (1), using the transparent conductive thin film ITO as the anode, the thickness is 50nm.

[0092] (2) Deposit PEDOT:PSS as a hole injection layer on the anode by a solution method, with a thickness of 50 nm.

[0093] (3) Depositing TFB as a hole transport layer on the hole injection layer by a solution method, with a thickness of 30 nm.

[0094] (4) On the hole transport layer, ZnCdS / ZnS is deposited as a quantum dot light-emitting layer by a solution method, with a thickness of 25 nm.

[0095] (5) Deposit ZnO nanoparticles: porphyrin magnesium (weight concentration ratio: 80:20) on the quantum dot light-emitting layer by solution method as the electron transport layer, with a thickness of 50nm.

[0096] (6) Depositing Ag on the electron transport layer as a cathode with a thickness of 100 nm by vapor deposition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com