Hard carbon composite material with long service life and high initial efficiency and preparation method thereof

A composite material and long-life technology, applied in structural parts, electrical components, battery electrodes, etc., can solve problems such as deviation of the bonding force between the cladding layer and the core hard carbon, poor conductivity, and small improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

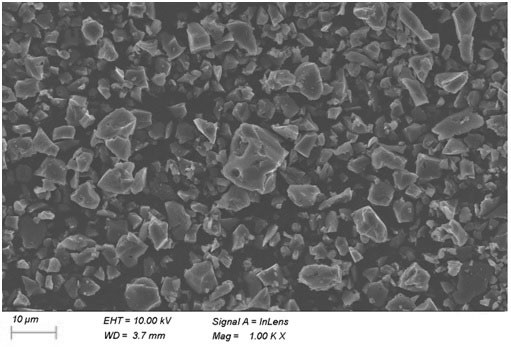

Image

Examples

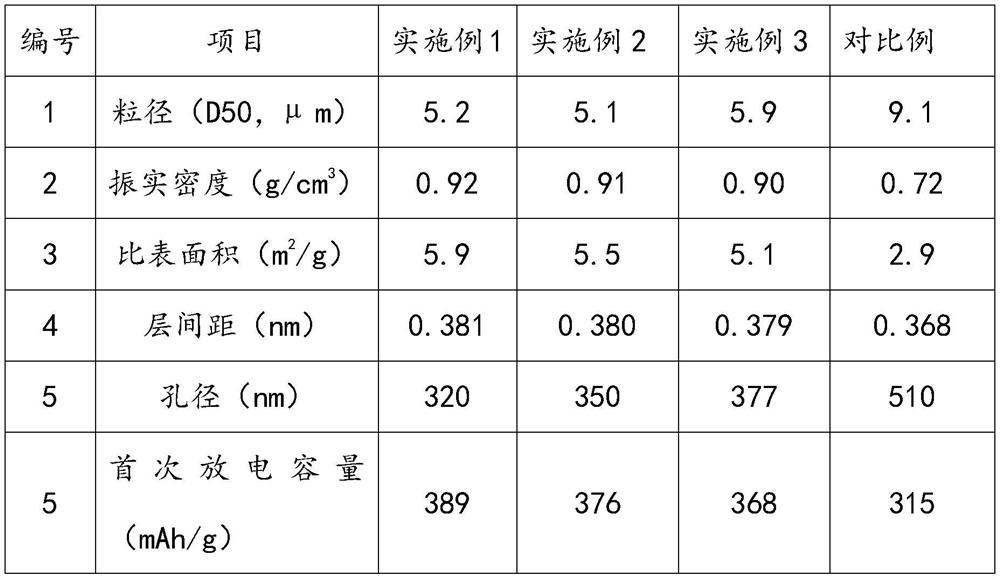

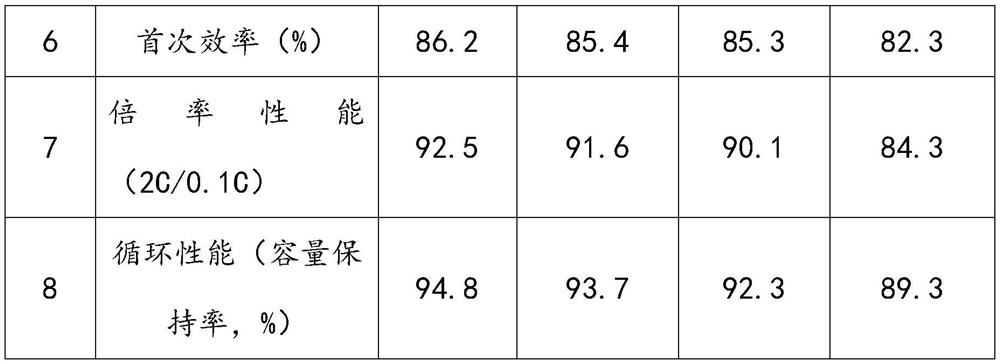

Embodiment 1

[0014] A preparation method of a long-life, high first-efficiency hard carbon composite material, comprising the following steps:

[0015] (1) 100g hard carbon is added in 500g 1-aminopropyl-3-methylimidazole nitrate ionic liquid, after stirring, obtaining mass concentration is 20% aminated ionic liquid coating hard carbon solution;

[0016] (2) 600g of aminated ionic liquid-coated hard carbon solution was added to 500g of 1,2-dimethyl-3-hydroxyethylimidazole p-toluenesulfonate, and after stirring, 5g of hydrogen peroxide was added to continue stirring, and then Transfer to a high pressure reactor, react at a temperature of 150°C for 3h, vacuum filter (0.05Mpa), and vacuum dry at 80°C for 24h to obtain an ionic liquid-coated hard carbon composite material;

[0017] (3) The ionic liquid-coated hard carbon composite material was moved to a tube furnace, and the temperature was raised to 900 °C for 3 hours at a heating rate of 3 °C / min to obtain a hard carbon composite material. ...

Embodiment 2

[0019] A preparation method of a long-life, high first-efficiency hard carbon composite material, comprising the following steps:

[0020] (1) 100g of hard carbon was added to 500g of 1-aminopropyl-3-methylimidazolium bis(trifluoromethanesulfonyl)imide salt ionic liquid, and after stirring evenly, the obtained mass concentration was 20% aminated ionic liquid package Hard-coated carbon solution;

[0021] (2) Add 600g of aminated ionic liquid-coated hard carbon solution to 500g of 1,2-dimethyl-3-hydroxyethylimidazole bis(trifluoromethanesulfonyl)imide salt ionic liquid, stir evenly, add 1 g of hydrogen peroxide continued to be stirred, then transferred to an autoclave, reacted at a temperature of 120 °C for 6 hours, vacuum filtered (0.05Mpa), and vacuum dried at 80 °C for 24 hours to obtain an ionic liquid-coated hard carbon composite material;

[0022] (3) Transfer the ionic liquid-coated hard carbon composite material to a tube furnace, and heat it up to 700 °C for 6 h at a h...

Embodiment 3

[0024] A preparation method of a long-life, high first-efficiency hard carbon composite material, comprising the following steps:

[0025] (1) 100g of hard carbon is added to 500g of 1-aminopropyl-3-methylimidazolium hexafluorophosphate, and after stirring, obtaining a mass concentration of 20% aminated ionic liquid coating hard carbon solution;

[0026] (2) 600g of aminated ionic liquid-coated hard carbon material was added to 500g of 1-hydroxyethyl-2,3-dimethylimidazolium chloride, and after stirring, 10g of hydrogen peroxide was added to continue stirring, and then transferred to the autoclave , react at 200 °C for 1 h, filter, and vacuum dry at 80 °C for 24 h to obtain ionic liquid-coated hard carbon composites;

[0027] (3) Transfer the ionic liquid-coated hard carbon composite material to a tube furnace, and heat it up to 1100 °C for 1 h at a heating rate of 5 °C / min to obtain a hard carbon composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com