Organic light-emitting device and preparation method thereof

An electroluminescent device and luminescent technology, which is applied in the direction of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the imbalance between electron and hole injection, the inability to generate photons, and hinder the light emission of organic electroluminescent devices Efficiency and other issues, to achieve the effect of improving luminous efficiency, improving balance, and improving injection capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

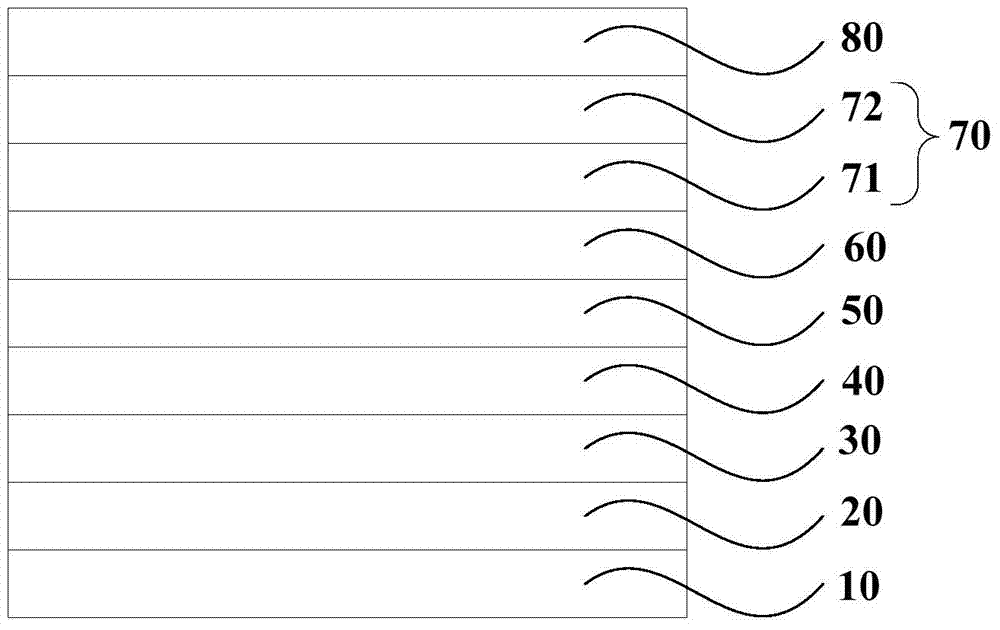

[0044] A method for preparing an organic electroluminescent device, comprising the steps of:

[0045] a) Production of anode conductive film: Rinse commercially available ordinary glass with distilled water and ethanol, soak it in isopropanol for one night, and use it as a glass substrate; An anode conductive film is prepared on the surface of the substrate, and the process conditions are: the degree of vacuum is 8×10 -4 Pa, the accelerating voltage is 700V, the magnetic field is 120G, and the power density is 25W / cm 2 ; The anode conductive film is made of indium tin oxide (ITO) with a thickness of 120nm.

[0046] b) Preparation of the hole injection layer: The hole injection layer was prepared on the surface of the anode conductive film layer by vacuum evaporation, and the process conditions were: the vacuum degree was 8×10 -4 Pa, the evaporation rate is 4nm / s; the material of the hole injection layer includes molybdenum trioxide (MoO 3 ), with a thickness of 35nm.

[00...

Embodiment 2

[0056] A method for preparing an organic electroluminescent device, comprising the steps of:

[0057] a) Production of anode conductive film: Rinse commercially available ordinary glass with distilled water and ethanol, soak it in isopropanol for one night, and use it as a glass substrate; An anode conductive film is prepared on the surface of the substrate, and the process conditions are: the degree of vacuum is 2×10 -3 Pa, the accelerating voltage is 300V, the magnetic field is 50G, and the power density is 40W / cm 2 ; The material of the anode conductive film is aluminum-doped zinc oxide (AZO), and the thickness is 300nm.

[0058] b) Preparation of the hole injection layer: The hole injection layer was prepared on the surface of the anode conductive film layer by vacuum evaporation, and the process conditions were: the vacuum degree was 2×10 -3Pa, the evaporation rate is 10nm / s; the material of the hole injection layer includes tungsten trioxide (WO 3 ), with a thickness ...

Embodiment 3

[0065] A method for preparing an organic electroluminescent device, comprising the steps of:

[0066] a) Preparation of anode conductive film: Rinse commercially available ordinary glass with distilled water and ethanol, soak it in isopropanol for one night, and use it as a glass substrate; An anode conductive film is prepared on the surface of the substrate, and the process conditions are: the degree of vacuum is 5×10 -5 Pa, the accelerating voltage is 800V, the magnetic field is 200G, and the power density is 1W / cm 2 ; The anode conductive film is made of indium-doped zinc oxide (IZO) with a thickness of 150nm.

[0067] b) Preparation of the hole injection layer: The hole injection layer was prepared on the surface of the anode conductive film layer by vacuum evaporation, and the process conditions were: the vacuum degree was 5×10 -5 Pa, the evaporation rate is 1nm / s; the material of the hole injection layer includes vanadium pentoxide (V 2 o 5 ), with a thickness of 55n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com