Preparation method of nitrogen and sulfur co-doped hierarchical pore carbon catalyst with acid and alkali resistant oxygen reduction catalytic performance

A nitrogen-sulfur co-doping, carbon catalyst technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of ammonium chloride application limitation, unfavorable substances and ion transport, etc., to achieve the effect of enhancing electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step S1: Dissolve 0.53 g of ammonium chloride in 50 mL of ultrapure water, then sequentially disperse 1 g of orange leaf powder and 5.7 g of nano-zinc oxide in the ammonium chloride solution, stir vigorously for 30 min, and place it in an oven at 80°C Medium drying for 12h to obtain material A1;

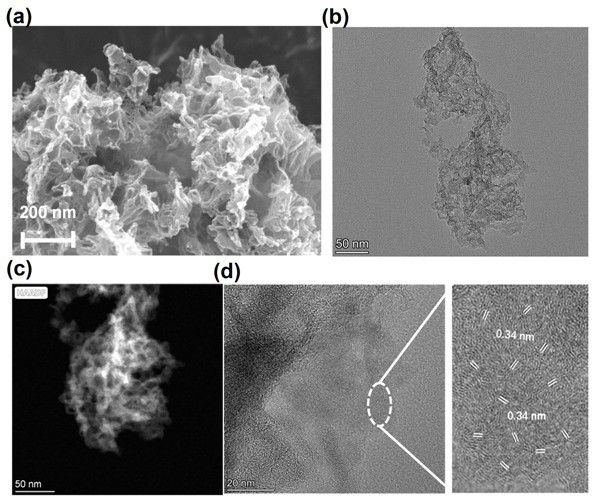

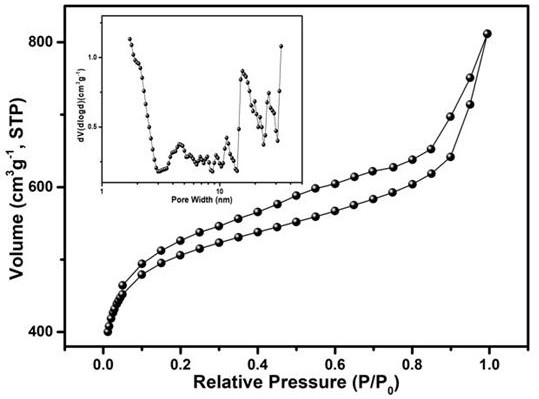

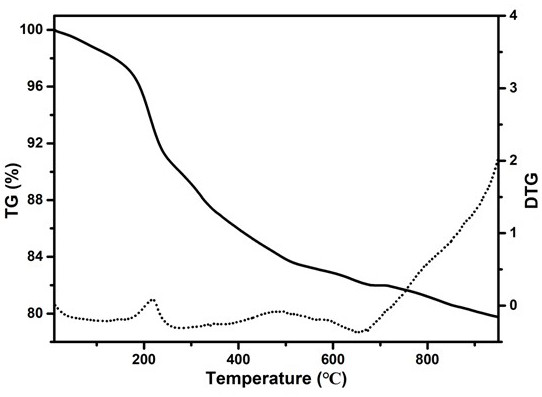

[0028] Step S2: fully grind the material A1 to a uniform powder state, collect the powder and place it in a corundum boat, and put it in a tube furnace for high temperature annealing, first in a continuous nitrogen atmosphere at 5°C min -1 The heating rate was increased from 25 °C to 400 °C and held for 60 min, and then heated at 5 °C min -1 The heating rate is heated to 900 ° C and kept for 60 min, and then naturally cooled to room temperature to obtain material B1. Under the high temperature molten state, the amphoteric oxide nano-zinc oxide can be combined with the hydrogen chloride released by the decomposition of ammonium chloride to release ammonia gas. This process is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com