Engineering muck pretreatment integrated equipment

A technology of engineering dregs and pretreatment, which is applied in the fields of grain treatment, sustainable waste treatment, solid waste management, etc., can solve the problems of difficulty in popularization and application, wide sources of engineering dregs, difficult treatment and disposal, etc., and achieve the potential of popularization and application Large, improved pretreatment efficiency, good pretreatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, but it is not intended to limit the present invention.

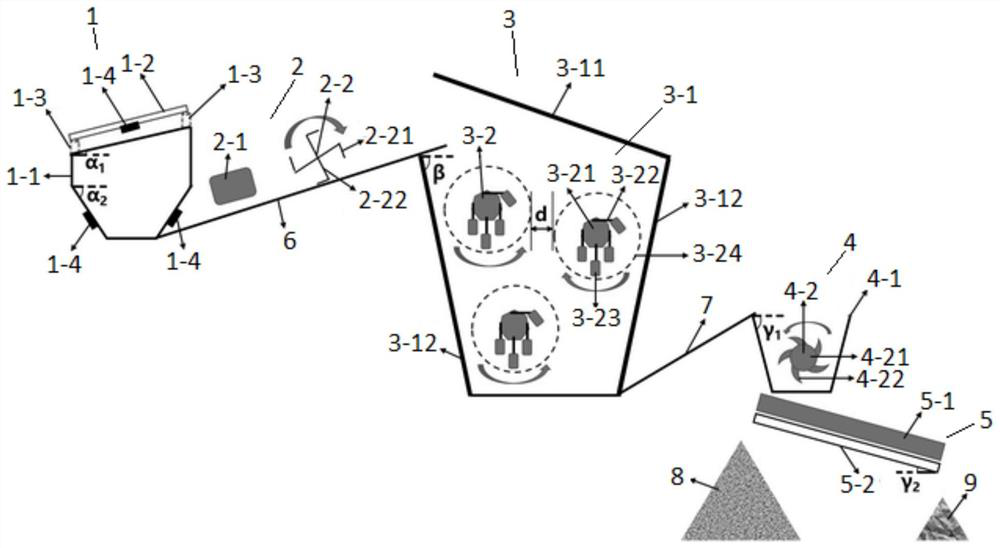

[0026] see figure 1 As shown, the integrated equipment for engineering slag pretreatment of the present invention includes an intelligent monitoring system, a conveying system and a feeding system 1, a multi-stage impurity removal system 2, a multi-stage crushing system 3, a granulation system 4 and a screening system connected in sequence. 5. The feeding system 1 includes a feeding bin 1-1 with vibration, a screen 1-2 with spring shock absorption is provided at the entrance of the feeding bin 1-1, and the multi-stage impurity removal system 2 includes an electromagnetic iron removing unit 2-1 and the light substance removal unit 2-2, the multi-stage crushing system 3 includes a crushing bin 3-1 and a three-stage rotary hammer unit arranged in the crushing bin 3-1, and the granulation system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com