Biodiesel synthesized by catalyzing vegetable fat with potassium phthalimide

A technology for catalyzing plants and potassium phthalimide with potassium phthalimide is applied in the field of chemical industry and can solve the problems of inability to separate homogeneous catalysts, easy deactivation of heterogeneous catalysts, long reaction time and the like , to achieve the effect of high conversion rate, convenient post-processing, safety and environmental protection problem solving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] The potassium phthalimide was prepared by conventional methods. 3 kilograms of phthalimide and 18 kilograms of dehydrated alcohol were added together in a 0.2 cubic reactor, stirred at room temperature for 10 minutes, and 100 kilograms of saturated ethanolic potassium hydroxide solution were slowly added dropwise simultaneously, stirred for 2 hours, filtered, and filtered. The cake was washed with absolute ethanol until neutral, and dried at 80° C. for 1 hour to obtain 3.69 kg of potassium phthalimide as a yellowish powder.

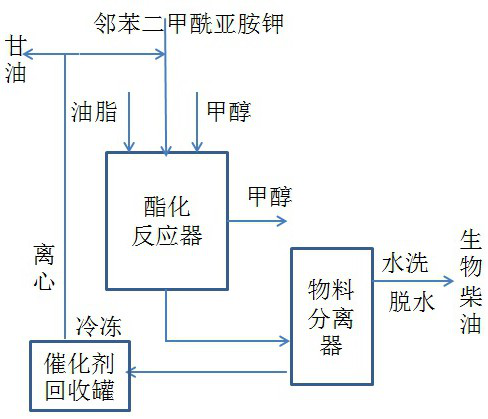

[0013] Dissolve 0.6 kg of potassium phthalimide in 16 kg of methanol, put it into a 0.2-cubic esterification reactor together with 60 kg of rapeseed oil, and heat and stir at 60 °C for 2 h. After the reaction was completed, excess methanol was distilled off at 78°C. Then in the material separator at room temperature, it is divided into upper and lower layers, the upper oil phase is the target product biodiesel, and the lower layer is the by-produc...

Embodiment 2

[0015] The yellowish powder potassium phthalimide 0.65 kilograms obtained in the example one is dissolved in 18 kilograms of methanol, and is dropped into the esterification reactor of 0.2 cubic meters with 60 kilograms of soybean oil, The reaction was heated and stirred at 55°C for 1.5h. After the reaction was completed, excess methanol was distilled off at 79°C. Then in the material separator at room temperature, it is divided into upper and lower layers, the upper oil phase is the target product biodiesel, and the lower layer is the by-product glycerol and catalyst mixture. The lower layer liquid was placed in a catalyst recovery tank and placed at 3°C for 8 hours, so that the catalyst dissolved in glycerol was precipitated, and the catalyst was separated from the glycerol by centrifugation. The centrifuged catalyst was washed with a small amount of ethanol to remove a small amount of glycerol remaining on the surface. Properly replenishing the lost catalyst, the oil co...

Embodiment 3

[0017] The yellowish powder potassium phthalimide 0.66 kilograms obtained in the example one is dissolved in 19 kilograms of methanol, drops into the esterification reactor of 0.2 cubic meters with 60 kilograms of corn oil, The reaction was heated and stirred at 62°C for 2.2h. After the reaction, excess methanol was distilled off at 80°C. Then in the material separator at room temperature, it is divided into upper and lower layers, the upper oil phase is the target product biodiesel, and the lower layer is the by-product glycerol and catalyst mixture. The lower layer liquid was put into the catalyst recovery tank and placed at 2°C for 6 hours, the catalyst dissolved in the glycerol was precipitated, and the catalyst was separated from the glycerol by centrifugation. The recovered catalyst was washed with a small amount of ethanol to remove a small amount of glycerol remaining on the surface. Properly replenishing the lost catalyst, the oil conversion rate can be maintained a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com