Portable high-precision automatic feeding drilling equipment

An automatic feed drilling, high-precision technology, applied in the direction of drilling/drilling equipment, feeding device, positioning device, etc., can solve the problems of fixed transmission ratio, inability to change processing parameters, high price, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

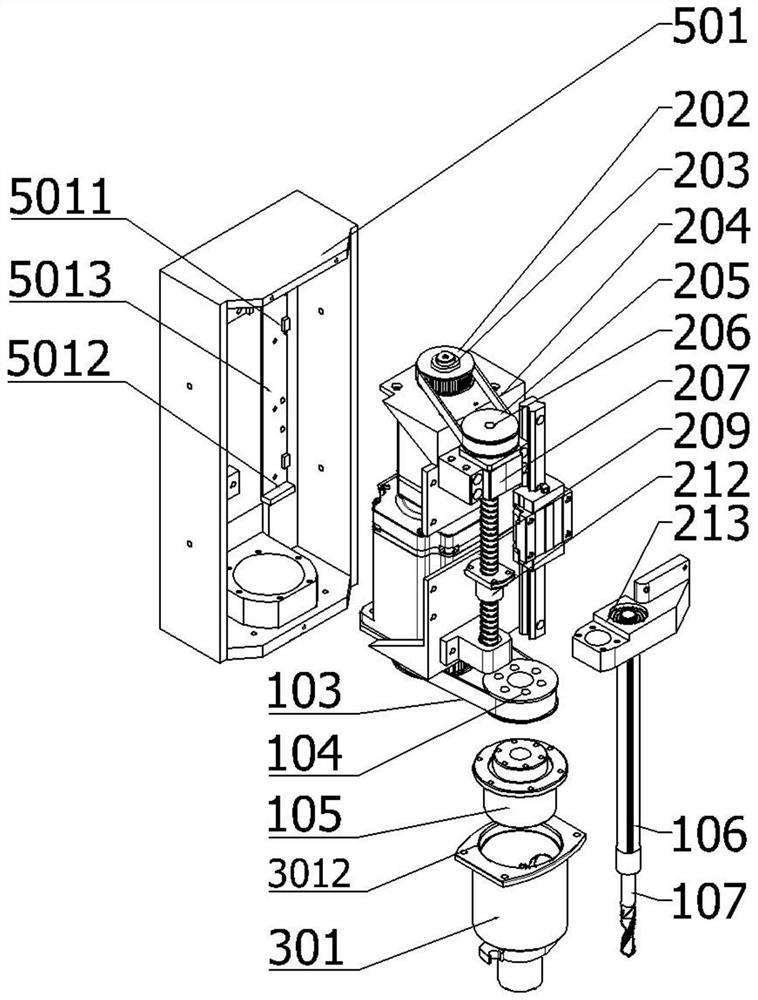

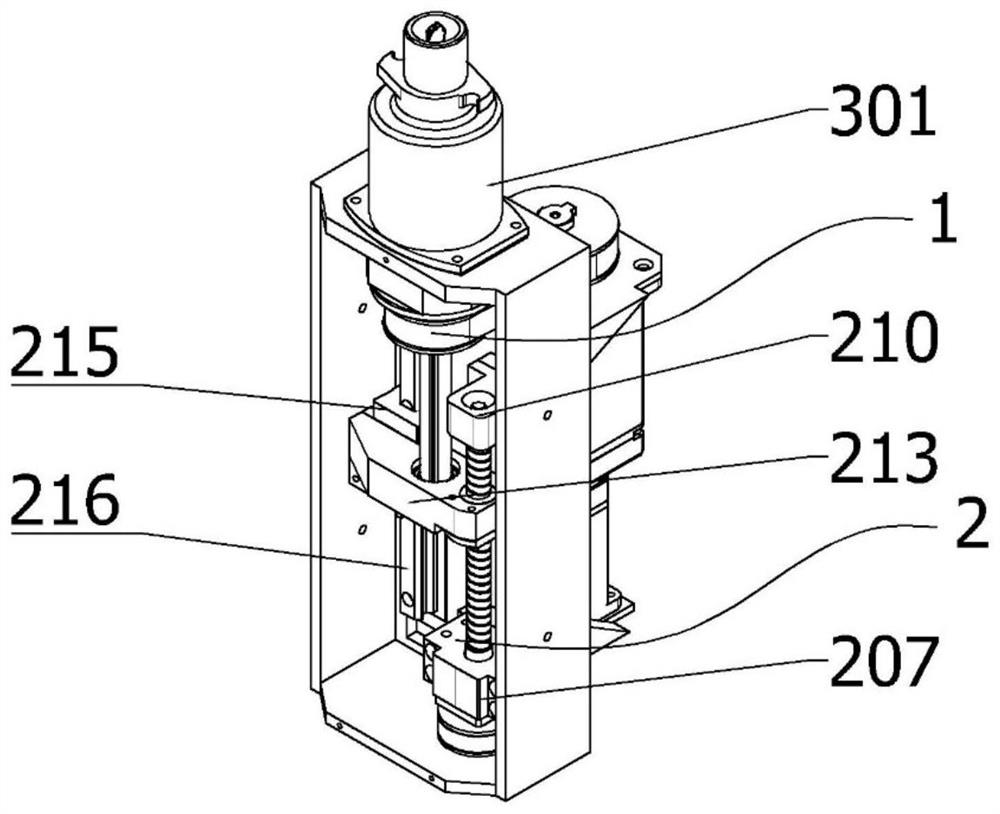

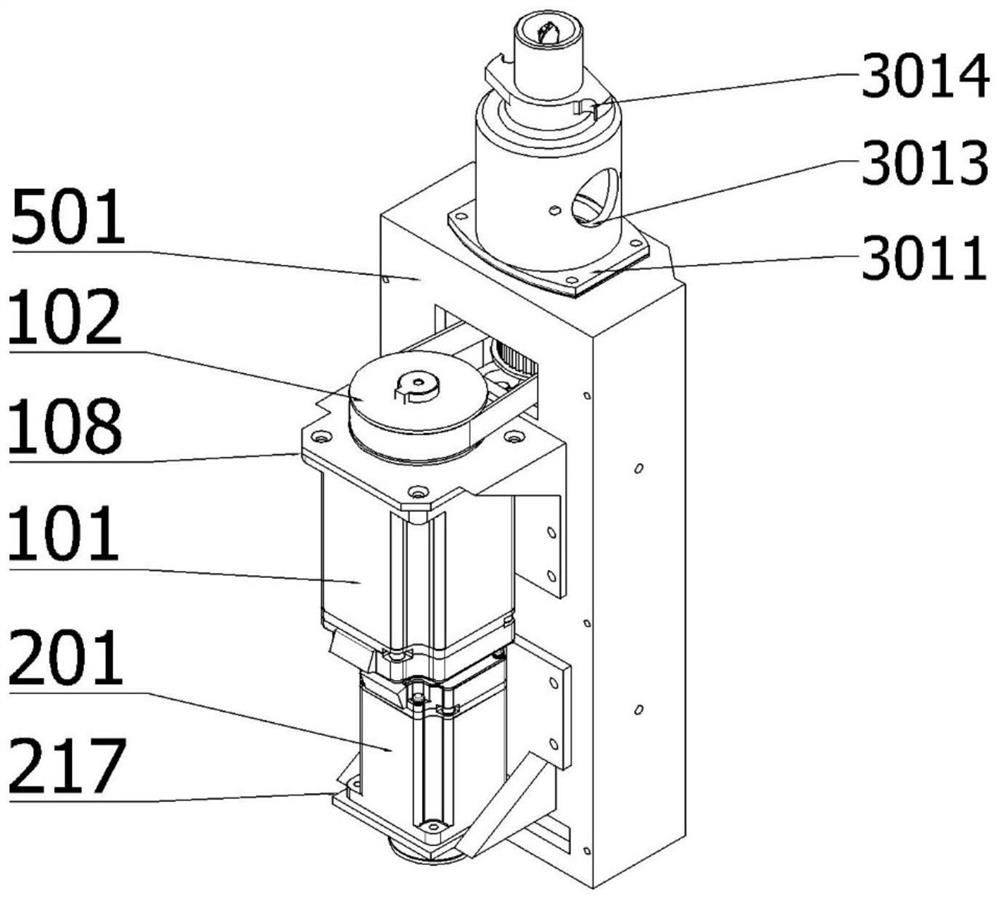

[0030] refer to Figure 1 to Figure 7 , a portable high-precision automatic feeding drilling equipment, including: a spindle module 1, a feeding module 2, a drill body fixing module 3, a control module 4 and a load-bearing frame.

[0031] In this embodiment, the spindle motor base 108 of the spindle module 1 is connected to the spindle motor 101 through bolts. The spindle motor 101 is a power source, and the spindle motor 101 and the spindle timing pulley 102 are tightly connected, and the spindle timing belt 103 is used to synchronize the spindle. The pulley 102 is connected to the spline timing pulley 104 . The spline timing pulley 104 is fastened to one end of the ball spline nut 105 by bolts, and the other end of the ball spline nut 105 is fitted into the mounting hole of the housing 501 . The ball spline nut 105 is divided into two parts: the outer stator and the inner rotor. The inner rotor part has ball grooves. The power is transmitted to the spline spindle 106 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com